Wear-resistant large white glaze, ceramic product with wear-resistant large white glaze and preparation method thereof

A technology of large white and raw materials, applied in the field of ceramic products, can solve the problems of poor wear resistance, unhealthy, poisoning, etc., and achieve the effect of smooth and delicate glaze, excellent wear resistance and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

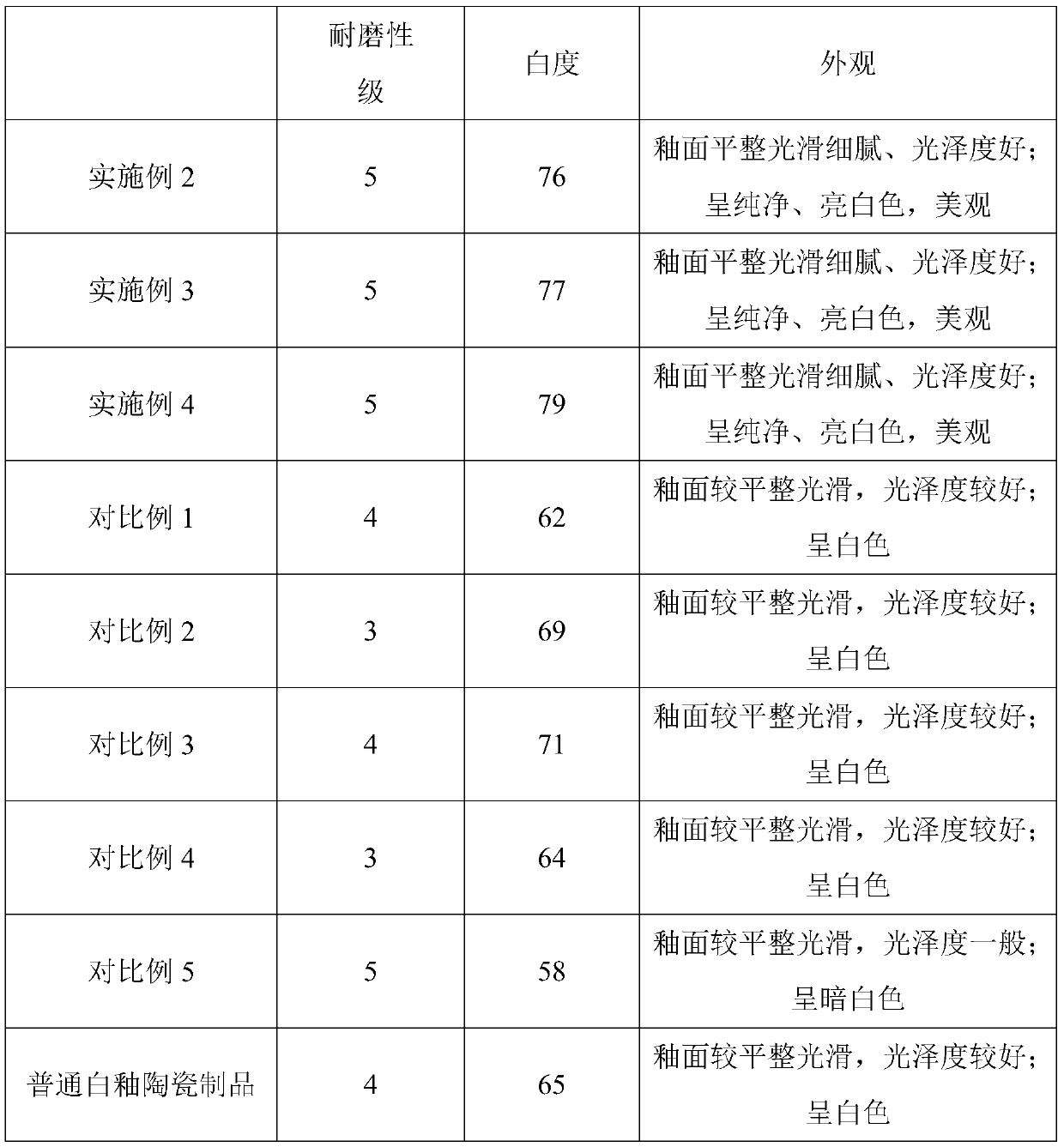

Examples

Embodiment 1

[0030] A wear-resistant large white glaze, which is made of the following raw materials in parts by weight: 55-65 parts of quartz powder, 13-17 parts of potassium feldspar powder, 7-10 parts of talcum powder, 8-14 parts of cryolite powder, and 5 parts of spodumene powder ~8 parts, manganese nitrate 3~5 parts, barium oxide 3~5 parts, magnesium oxide 3~5 parts, titanium oxide 4~6 parts, scandium oxide 2~4 parts, high boron frit 5~8 parts.

[0031] Preferably, the wear-resistant large white glaze is made of the following raw materials in parts by weight: 60 parts of quartz powder, 15.2 parts of potassium feldspar powder, 8.5 parts of talc powder, 11.5 parts of cryolite powder, 7.5 parts of spodumene powder, and 4.2 parts of manganese nitrate , 3.3 parts of barium oxide, 3 parts of magnesium oxide, 5.1 parts of titanium oxide, 3 parts of scandium oxide, and 6.5 parts of high boron frit.

[0032] Preferably, the quartz includes α-quartz and β-quartz.

[0033] Preferably, the mass ...

Embodiment 2

[0044] A wear-resistant large white glaze, made of the following raw materials in parts by weight: 55 parts of quartz powder, 13 parts of potassium feldspar powder, 7 parts of talc powder, 8 parts of cryolite powder, 5 parts of spodumene powder, 3 parts of manganese nitrate, 3 parts of barium, 3 parts of magnesium oxide, 4 parts of titanium oxide, 2 parts of scandium oxide, 5 parts of high boron frit.

[0045] In this embodiment, the quartz includes α-quartz and β-quartz.

[0046] In this embodiment, the mass ratio of α-quartz to β-quartz in the quartz is 100:6.

[0047] In the present embodiment, the manganese nitrate is manganese nitrate tetrahydrate (Mn(NO 3 ) 2 4H 2 O).

[0048] In this embodiment, the titanium oxide is nano titanium dioxide.

[0049] In this embodiment, the boron content of the high boron frit is 10%, and the lead content is less than 0.01%.

[0050] In this embodiment, a ceramic product is also provided, which includes a body and a glaze layer cove...

Embodiment 3

[0057] A wear-resistant large white glaze, made of the following raw materials in parts by weight: 65 parts of quartz powder, 17 parts of potassium feldspar powder, 10 parts of talc powder, 14 parts of cryolite powder, 8 parts of spodumene powder, 5 parts of manganese nitrate, 5 parts of barium, 5 parts of magnesium oxide, 6 parts of titanium oxide, 4 parts of scandium oxide, 8 parts of high boron frit.

[0058] In this embodiment, the quartz includes α-quartz and β-quartz.

[0059] In this embodiment, the mass ratio of α-quartz to β-quartz in the quartz is 100:8.

[0060] In the present embodiment, the manganese nitrate is manganese nitrate tetrahydrate (Mn(NO 3 ) 2 4H 2 O).

[0061] In this embodiment, the titanium oxide is nano titanium dioxide.

[0062] In this embodiment, the boron content of the high boron frit is 15%, and the lead content is less than 0.01%.

[0063] In this embodiment, a ceramic product is also provided, including a body and a glaze layer coverin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap