A prefabricated ceramsite concrete hollow slab shaped membrane and its construction method

A ceramsite concrete and hollow slab technology, which is applied in basic structural engineering, construction, protection devices, etc., can solve the problems of reduced work efficiency and troublesome operation, and achieve the effect of reducing production cost, simple operation and ensuring shape stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

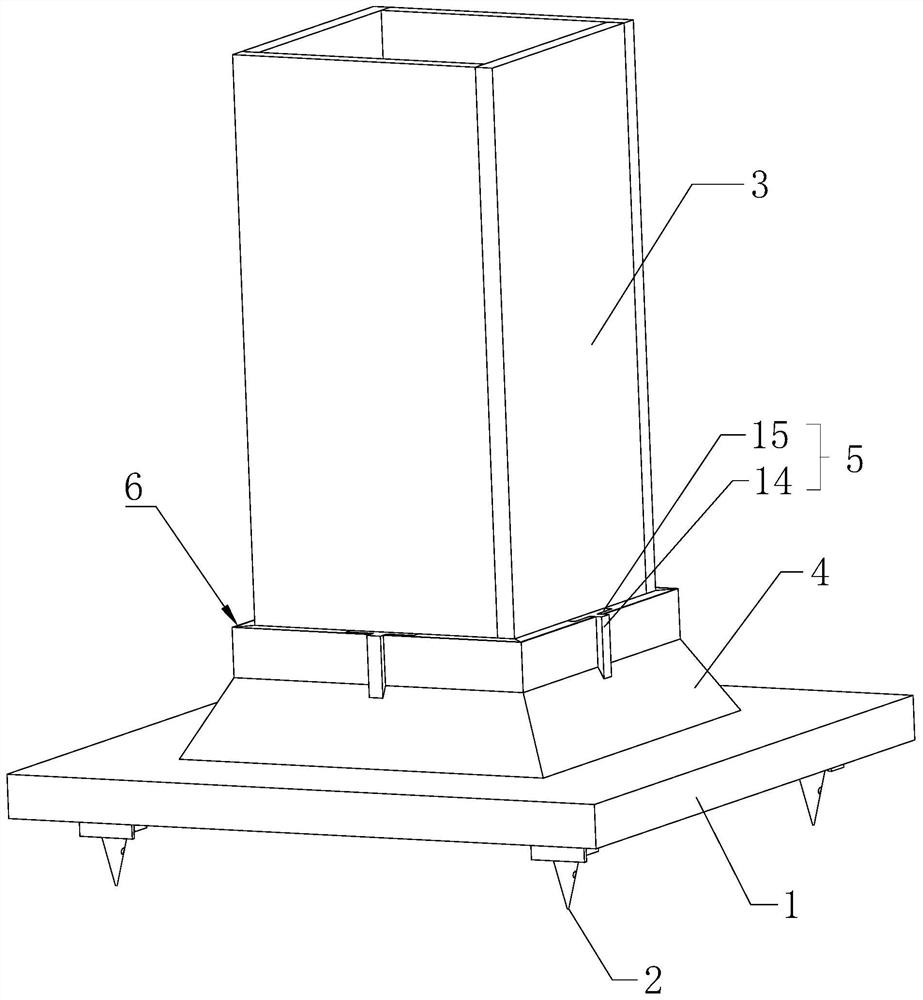

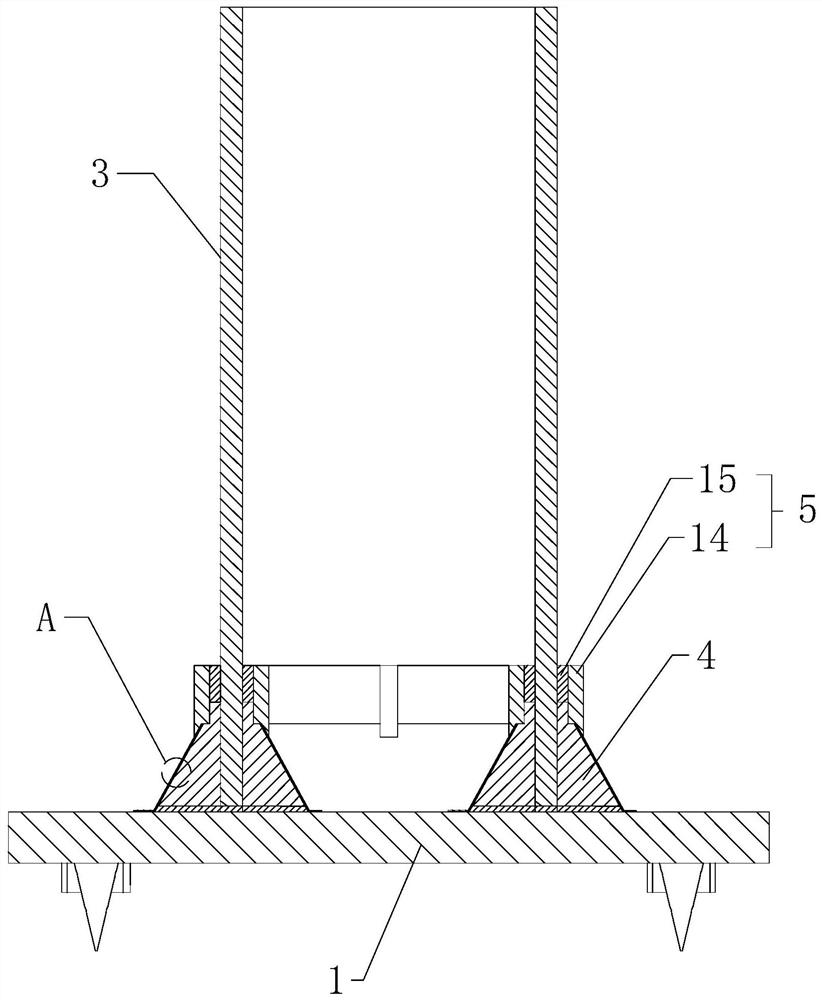

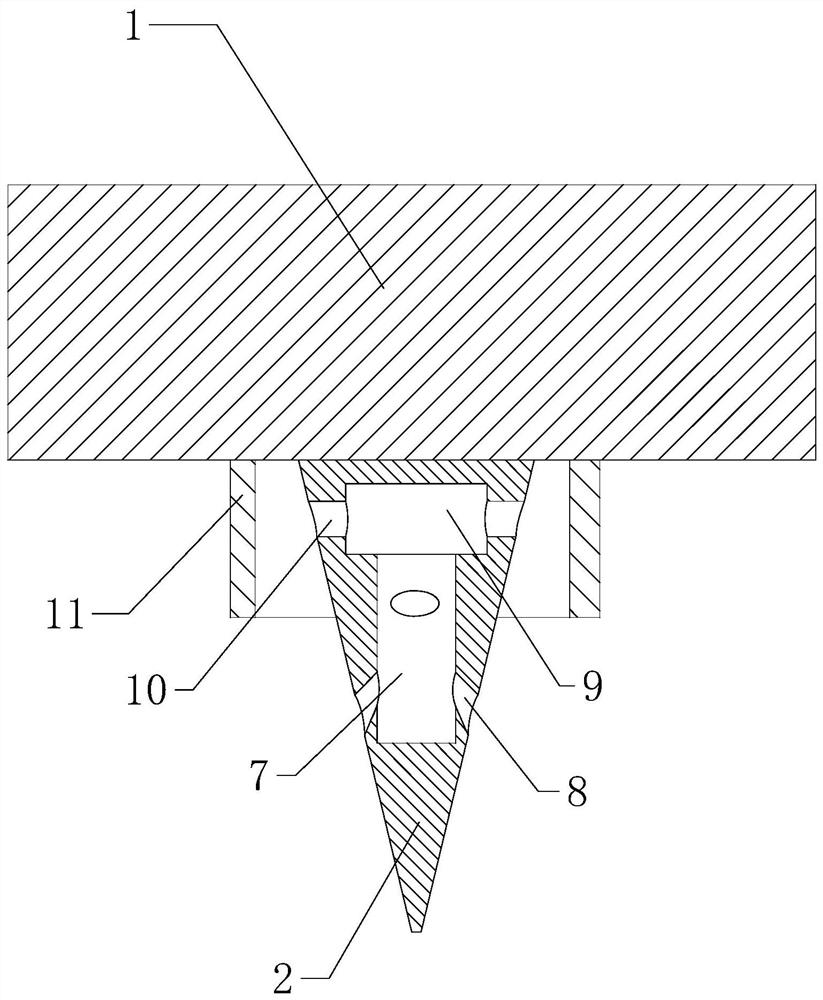

[0042] The invention discloses a prefabricated ceramsite concrete hollow slab shaped membrane, such as figure 1 and figure 2 As shown, it includes a pile cap plate 1, a number of fixed piles 2 arranged on the lower surface of the pile cap plate 1, a shaped plate 3 arranged around the upper surface of the pile cap plate 1, and arranged in the bottom end of the shaped plate 3 The stabilizing platform 4 between the outer wall and the pile cap plate 1 and the stabilizing connecting block 5 embedded in the stabilizing platform 4, the stabilizing connecting block 5 protruding from the side of the stabilizing platform 4 away from the shaping plate 3 along the horizontal direction, the stabilizing platform 4 A waterproof film layer 6 is adhered between the side away from the shaped plate 3 and the pile cap plate 1. The stable platform 4 in the present invention has a right-angled trapezoidal platform at the bottom and a rectangular platform at the top, and four shaped plates 3 flat ...

Embodiment 2

[0047] A construction method for prefabricated ceramsite concrete hollow slab shaped membrane, such as Figure 5 , Figure 6 , Figure 7 and Figure 8 shown, including the following construction steps:

[0048] According to the shape of the stabilizing platform 4 in Embodiment 1 of the present invention, the top end of the construction tooling plate of the present invention is a vertical plate, and the bottom end is an inclined plate.

[0049] S1: According to the size of the shaped membrane, prefabricate the construction tooling board-the first shaped shroud 16 and the second shaped shroud 17, the first shaped shroud 16 is located in the second shaped shroud 17, and the first shaped shroud The distance between the shroud 16 and the second shaped shroud 17 is greater than the thickness of the shaped board 3;

[0050] Then at the outside of the top vertical plate of the first shaped coaming plate 16 and the inboard of the top vertical plate of the second shaped coaming plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com