Drill stand face pipe column treatment device

A processing device and drilling floor technology, applied in drill pipes, drill pipes, casings, etc., can solve the problems of small market promotion value, low degree of automation, affecting working space, etc., to minimize installation space requirements and simple displacement Convenience and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

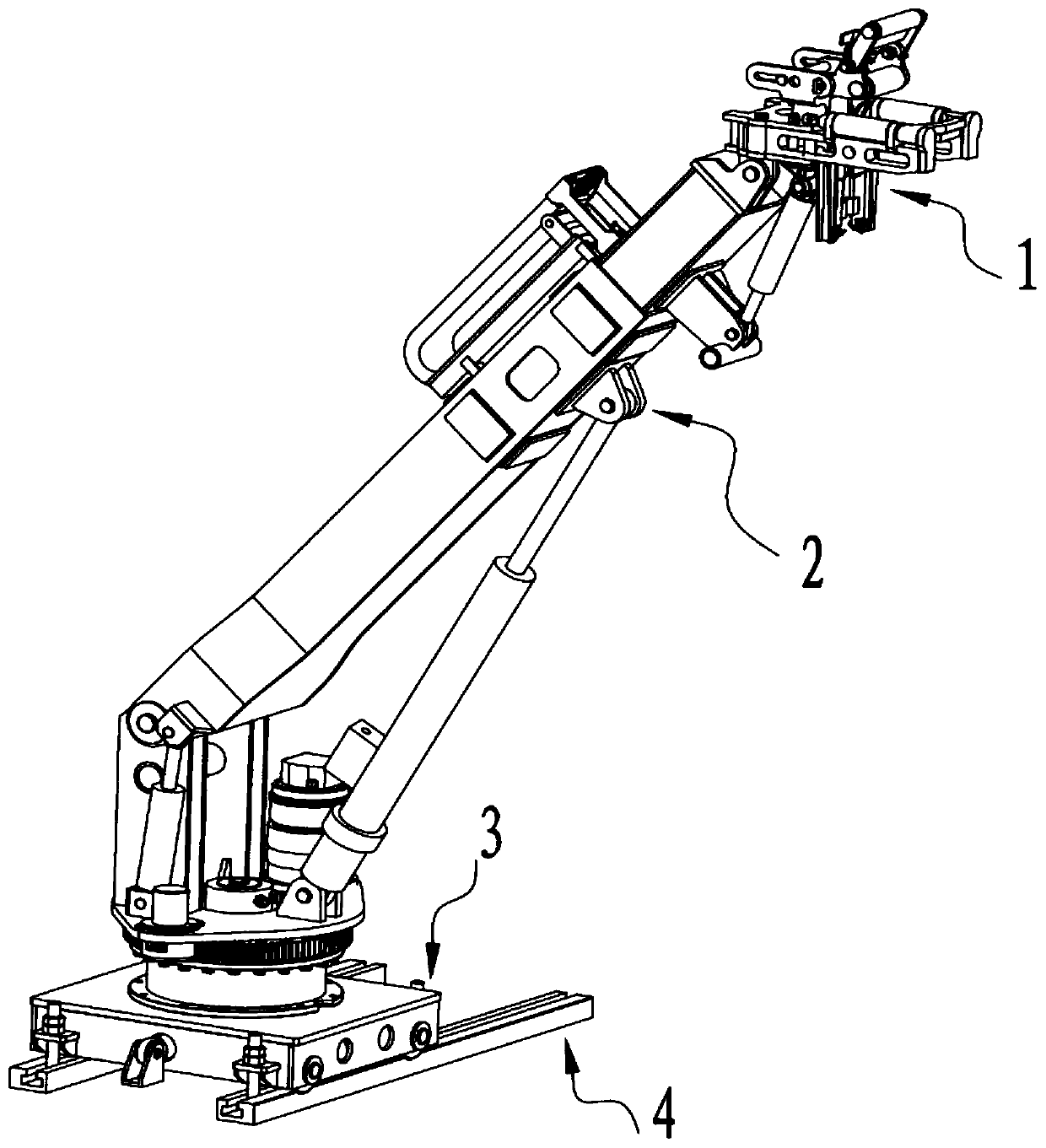

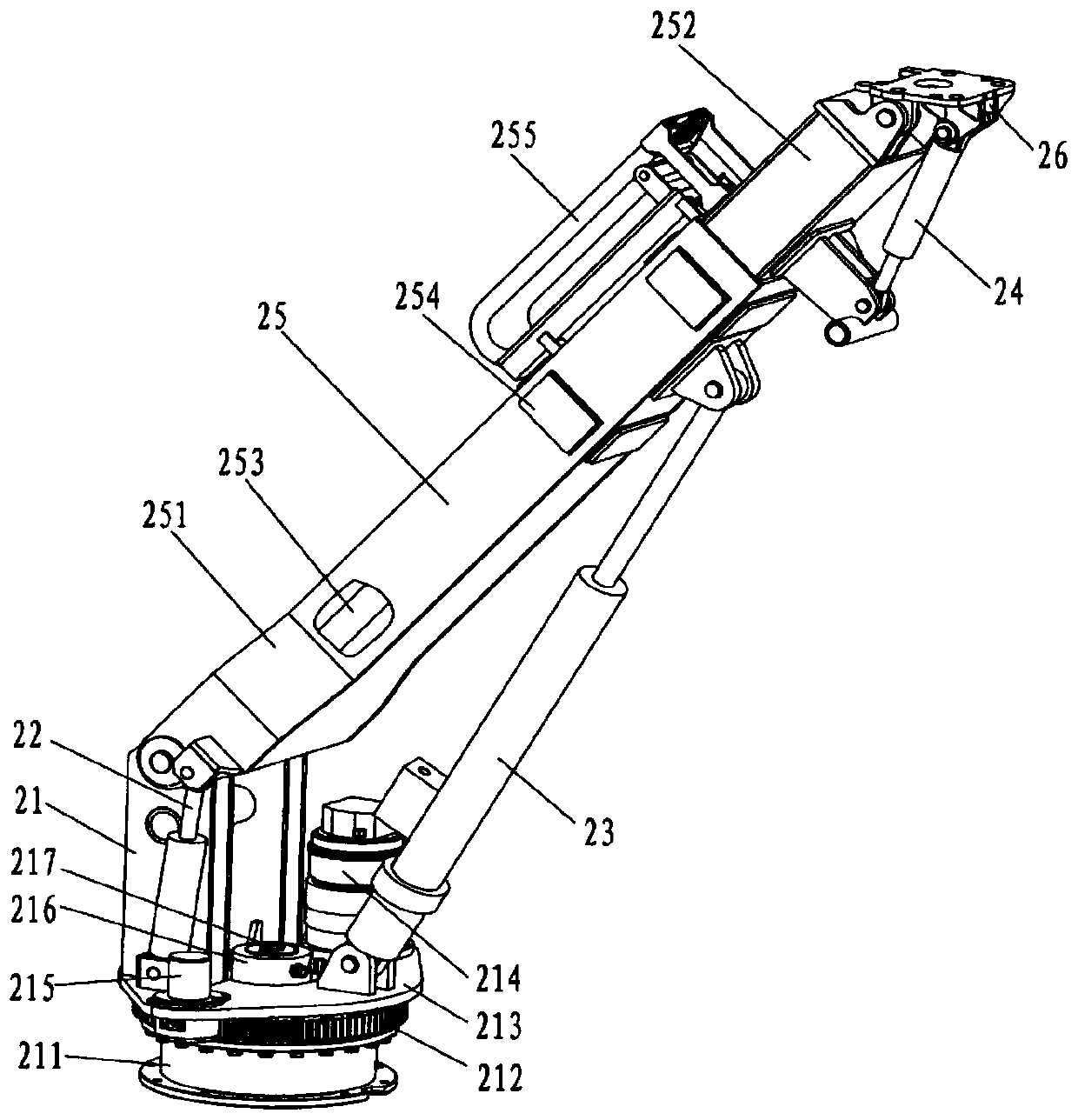

[0050] The structure of a pipe string processing device on the drilling floor of the present invention is as follows: figure 1 As shown, it includes a sliding track 4 with a T-shaped groove, the sliding track 4 is fixed on the drill floor surface, and the sliding track 4 is provided with a moving assembly 3 to slide, and the moving assembly 3 is fixedly connected with a mechanical arm assembly 2. A pipe string processing tong head 1 is installed on the top of the arm assembly 2, the mechanical arm assembly 2 is used to adjust the transport pipe string and keep the pipe string processing tong head 1 level, and the pipe string processing tong head 1 is used to clamp the pipe string.

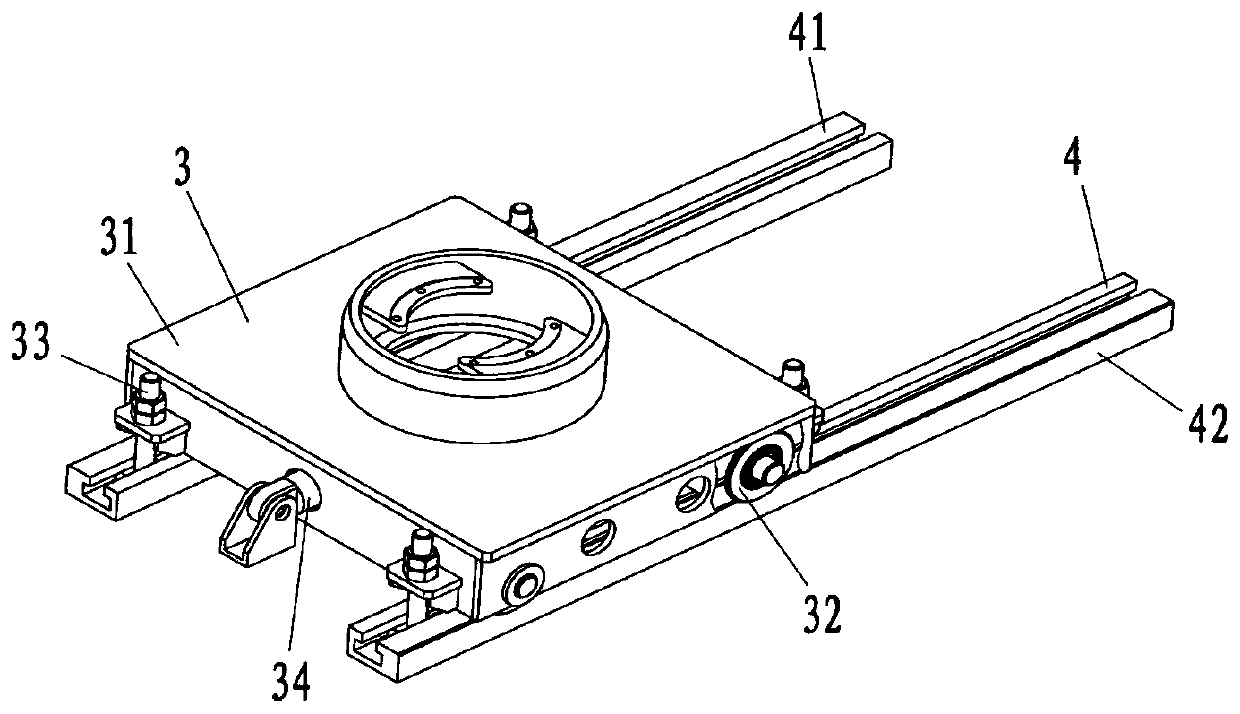

[0051] Such as figure 2 As shown, the moving assembly 3 includes a pulley 31, the pulley 31 slides on the sliding track 4 through the rollers 32, the upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com