Fuel nozzle assembly with main pipe and brazing method

A technology of fuel nozzles and manifolds, which is applied in the direction of combustion methods, fuel flow passages of turbines/propulsion devices, combustion chambers, etc., and can solve the problems of difficult bottom flatness, poor sealing, and difficult processing, etc., and achieves simple structure and guaranteed The effect of airtightness and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

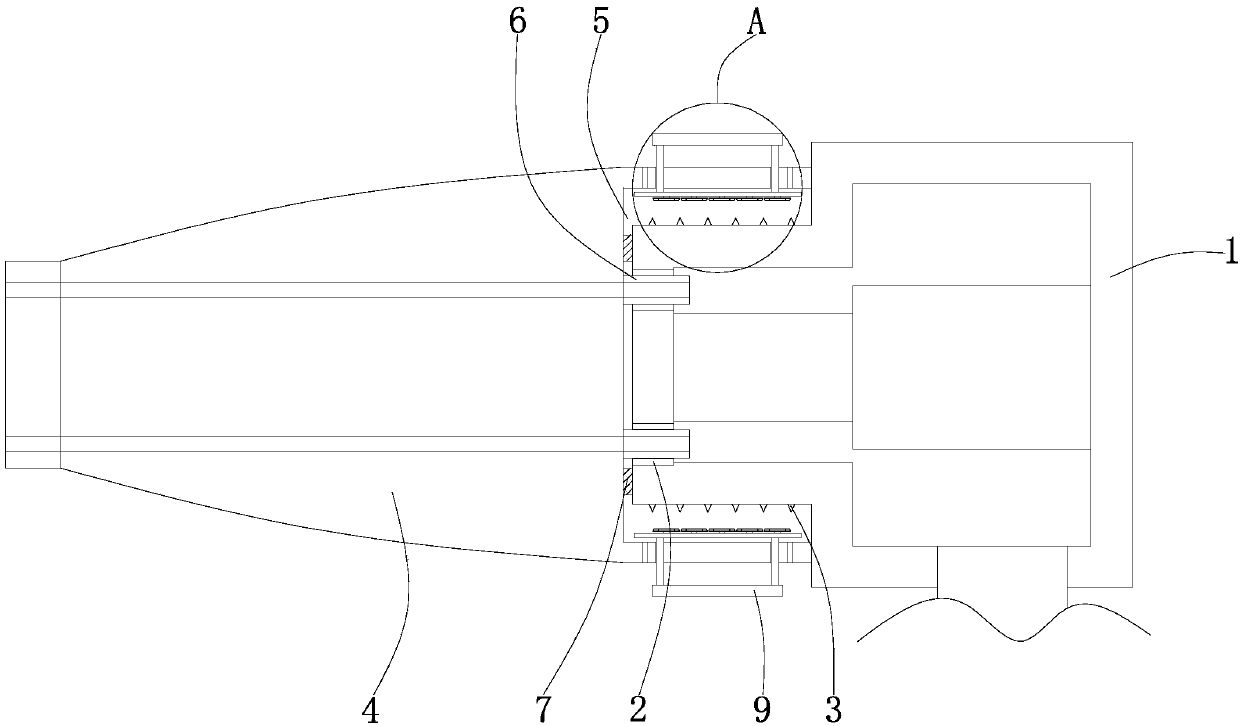

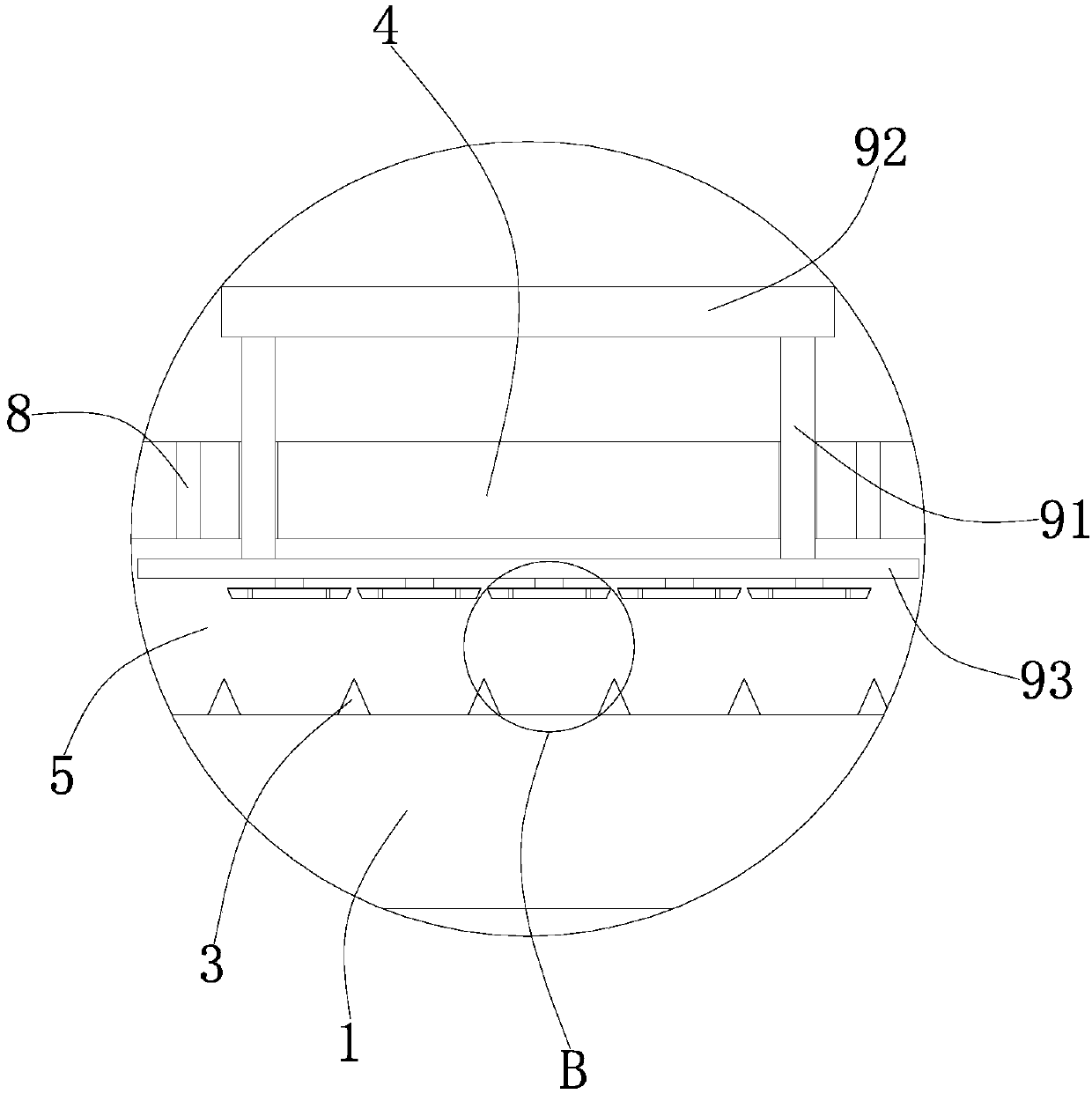

[0025] Such as Figure 1-3 As shown, a fuel nozzle assembly with a manifold includes a manifold 1, a fixed sleeve 2, a bearing tooth 3, a nozzle 4, a groove 5, a boss post 6, a buffer washer 7, a brazing hole 8, and a limit device 9, The number of fixed sleeves 2 is two, and the two fixed sleeves 2 are symmetrically arranged on the top and bottom of the left side of the main pipe 1. The number of load-bearing teeth 3 is twelve, and the load-bearing teeth 3 are symmetrically fixedly connected to the top and bottom of the main pipe 1 respectively. On the left side of the bottom, the nozzle 4 is set on the left side of the main pipe 1, the groove 5 is opened in the middle of the right side of the nozzle 4, the number of the bosses 6 is two, and the two bosses 6 are symmetrically arranged on the left side of the groove 5 inner cavity At the top and bottom of the side, the buffer gasket 7 is arranged in the middle of the left side of the inner cavity of the groove 5, and the number...

Embodiment 2

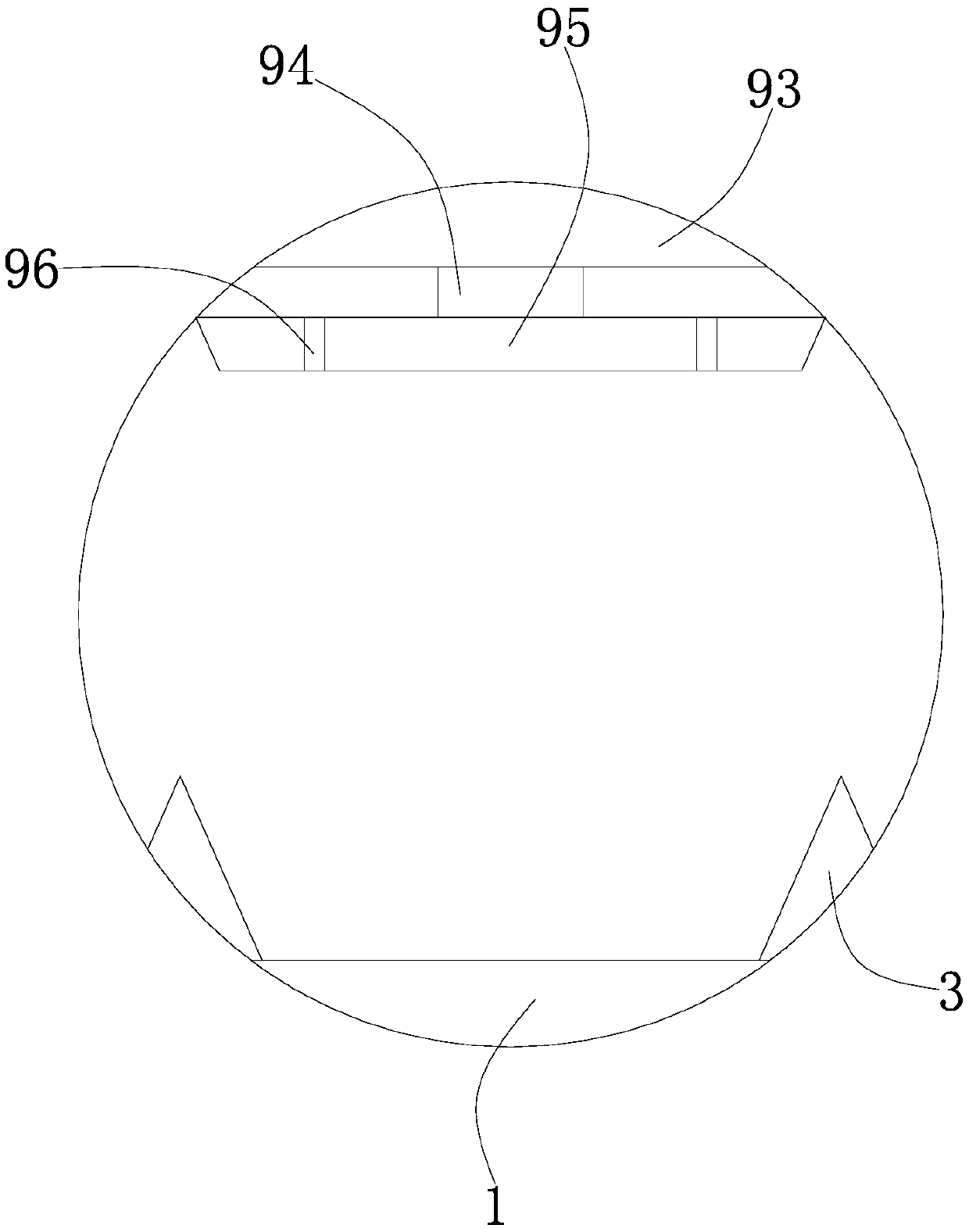

[0027] On the basis of Embodiment 1, the limiting device 9 includes a connecting rod 91, a pressing plate 92, a bearing plate 93, a support rod 94, a limiting plate 95, and a through hole 96. The number of connecting rods 91 is two, two The connecting rods 91 are symmetrically arranged on the left and right sides between the pressing plate 92 and the bearing plate 93, the number of the supporting rods 94 is five, and the supporting rods 94 are uniformly fixedly connected to the side of the bearing plate 93 away from the connecting rod 91 , the number of limiting plates 95 is five, the limiting plate 95 is evenly arranged on one side of the bearing plate 93, the number of through holes 96 is ten, and the ten through holes 96 are respectively set on five limiting plates 95 left and right ends.

Embodiment 3

[0029] On the basis of Examples 1 and 2, the fixed sleeve 2 runs through the wall on the left side of the main pipe 1 and extends to the inside of the main pipe 1. The fixed sleeve 2 is closely attached to the wall of the main pipe 1 and is fixedly connected. It is arranged at one end away from the main pipe 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap