System and method for intelligent monitoring and real-time compensation of automation device

An automatic equipment and real-time compensation technology, which is applied in the general control system, test/monitoring control system, control/regulation system, etc., can solve the problem that the fault identification program cannot judge the cause, and achieve the effect of correcting system deviation and optimizing parameter configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

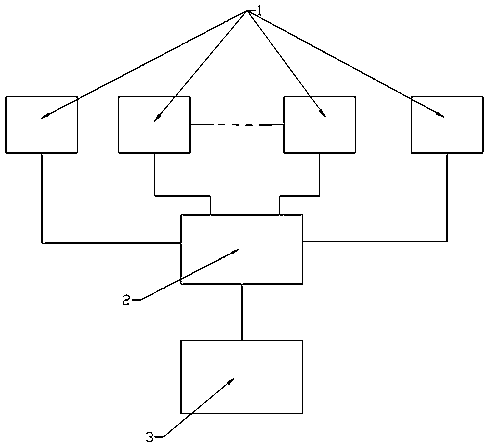

[0032] Such as figure 1 , figure 2 As shown, the intelligent monitoring and real-time compensation system for automation equipment in the present invention includes a device running real-time data transceiver module 1, a data transceiver and monitoring module 2, and a data coupling analysis module 3 that are electrically connected in sequence, and the real-time data of the device running The transceiver module 1 is connected with the working parts of the automation equipment.

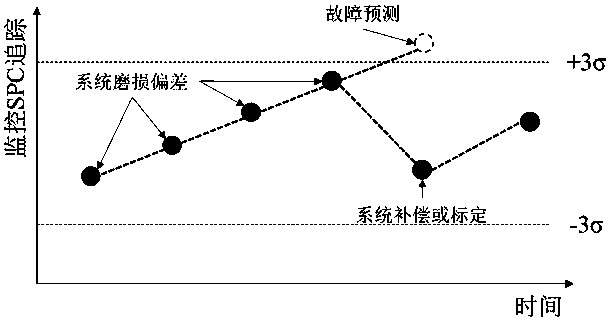

[0033] The data coupling analysis module 3 includes a statistical process control module.

[0034] The data coupling analysis module 3 includes a process capability index calculation module.

[0035] The device operation real-time data transceiver module 1 includes a numerical control processing data transceiver module, a three-dimensional measuring instrument data transceiver module, a glue dispenser data transceiver module, an optical detection data transceiver module, an equipment component data t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com