Household minitype walnut automatic shell breaking machine

A shell breaking machine, walnut technology, applied in household appliances, applications, kitchen utensils and other directions, can solve the problems of high use cost, high equipment cost, unsafe, etc., to improve the quality of life, high degree of automation, low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

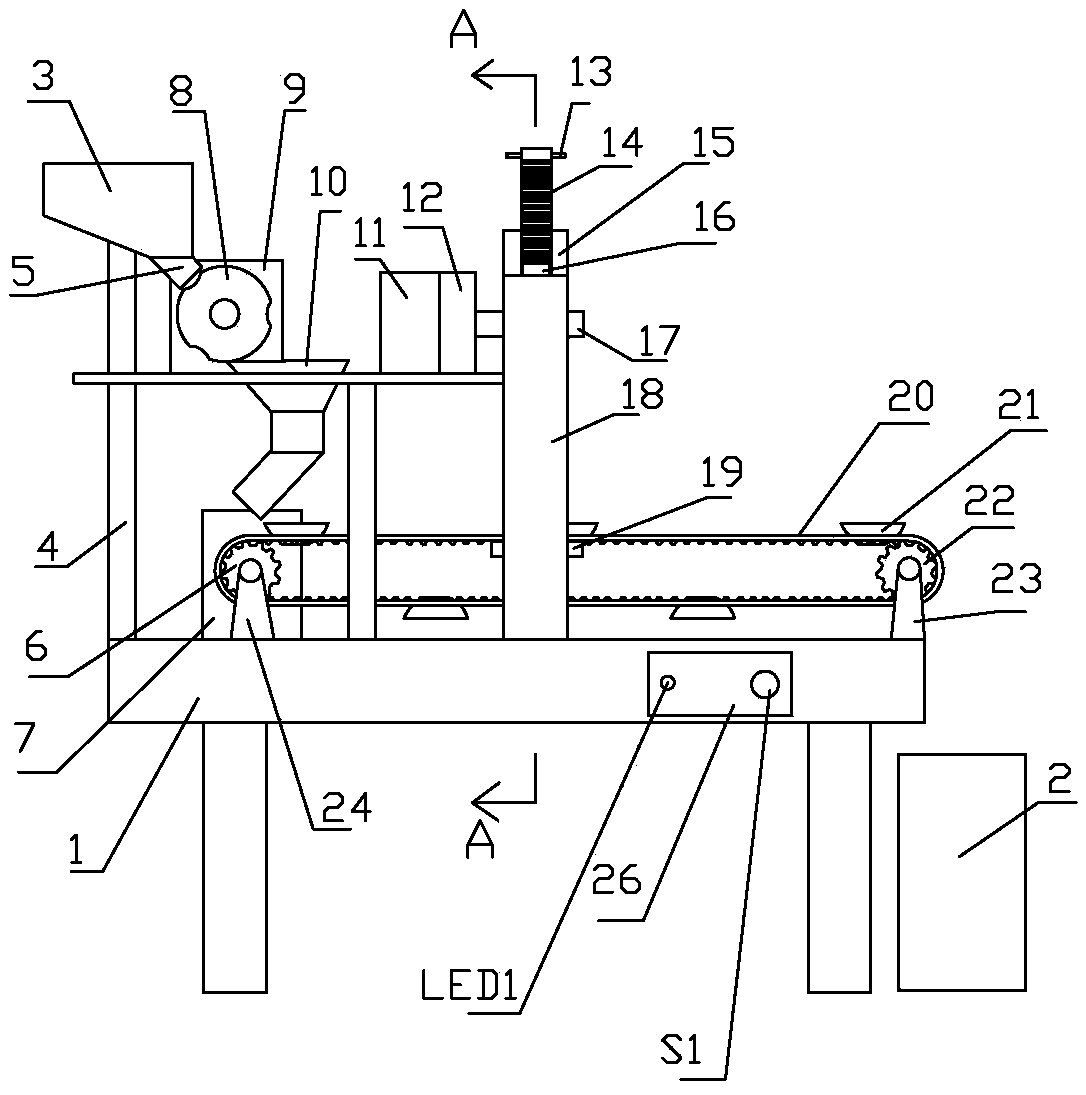

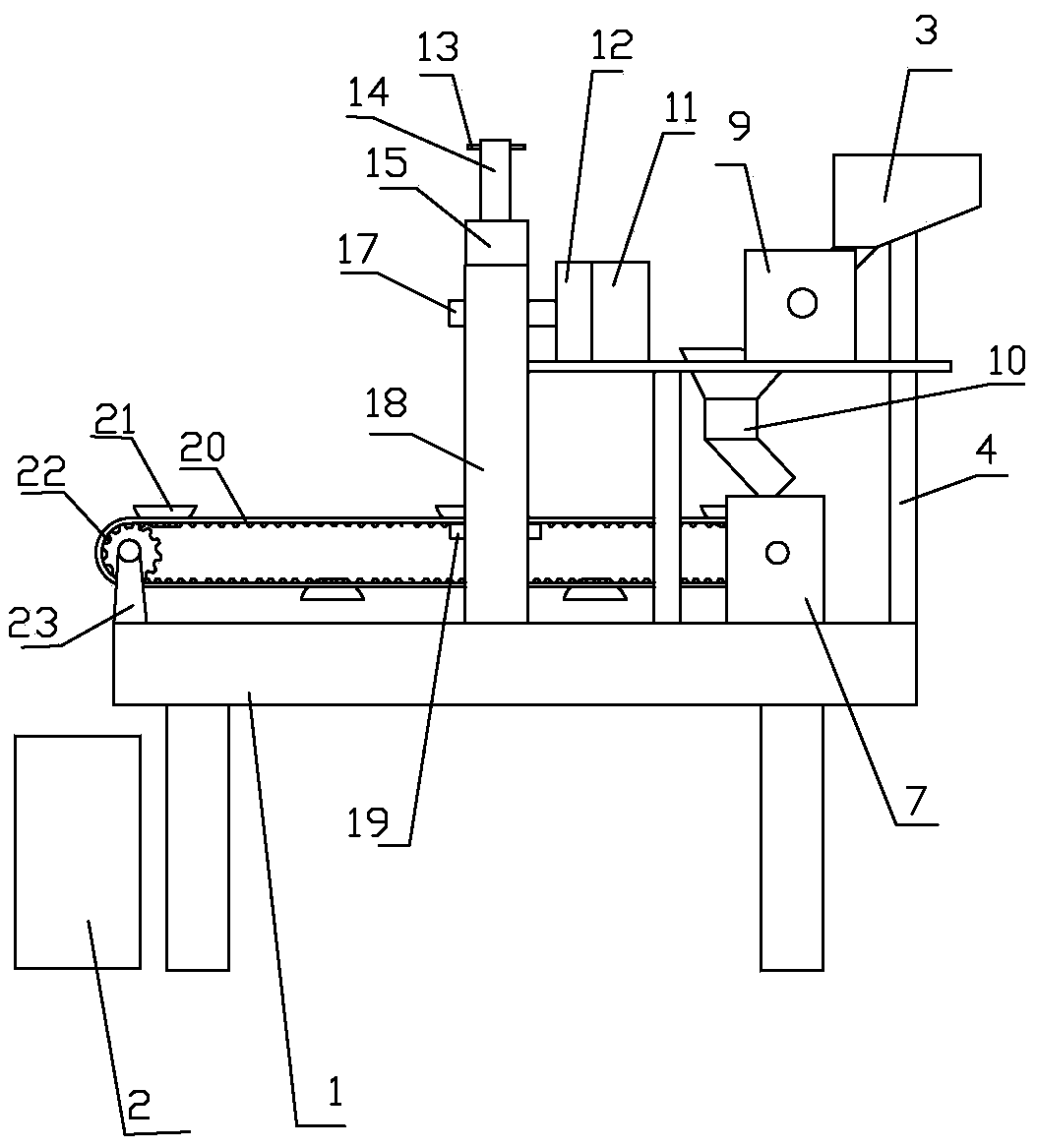

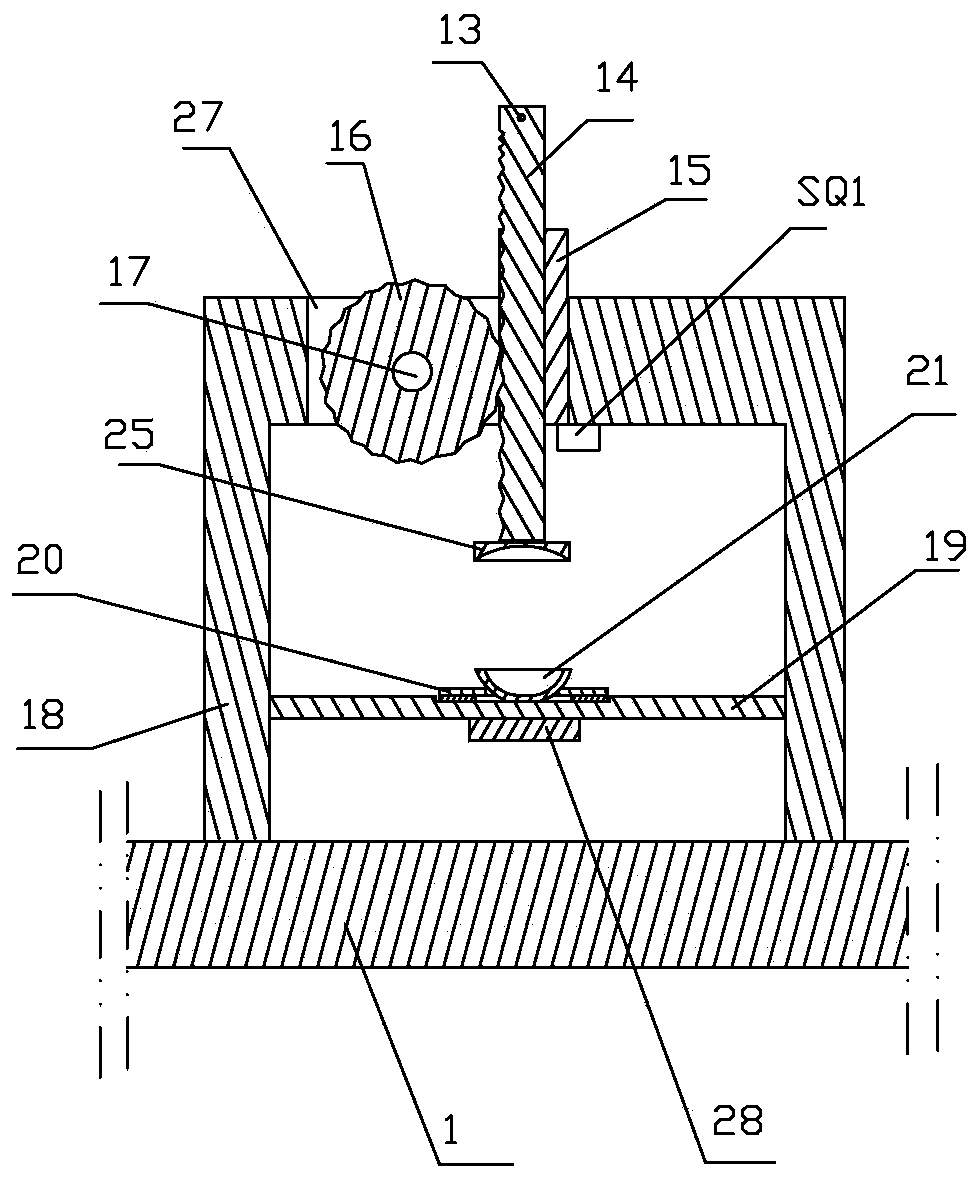

[0047] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 Make the invention.

[0048] The domestic small-sized walnut automatic shell breaking machine includes a frame 1, a collection bucket 2, a feeding bucket 3, a controller 26, a feeding stepping motor 9, a feeding stepping motor 7, a broken shell DC motor 11, a reducer 12 and Conveyor belt 20, the rotating shaft of broken shell DC motor 11 is connected to the reducer 12 for transmission, and the front end of frame 1 is fixed with feeding bucket 3 through bracket 4, and the rear end of frame 1 is provided with collecting bucket 2 and controller 26 Connect the feeding stepper motor 9, the feeding stepper motor 7 and the crushed shell DC motor 11 through wires respectively, and control the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com