Residue sorting equipment and residue sorting method thereof

A residue and sorting technology, applied in chemical instruments and methods, solid separation, sieves, etc., can solve problems such as clogging of the slag outlet, and achieve the effect of improving mechanical efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

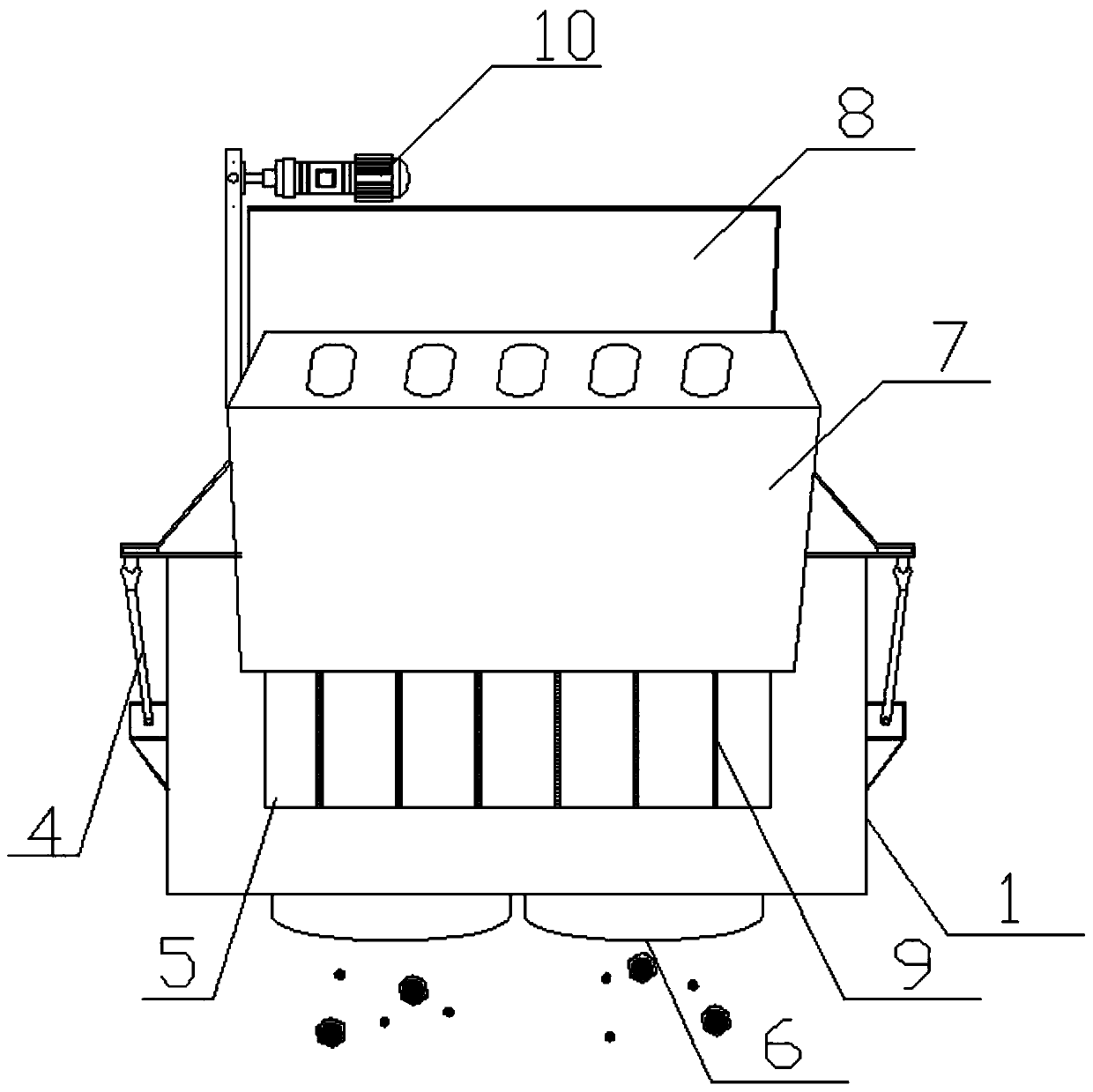

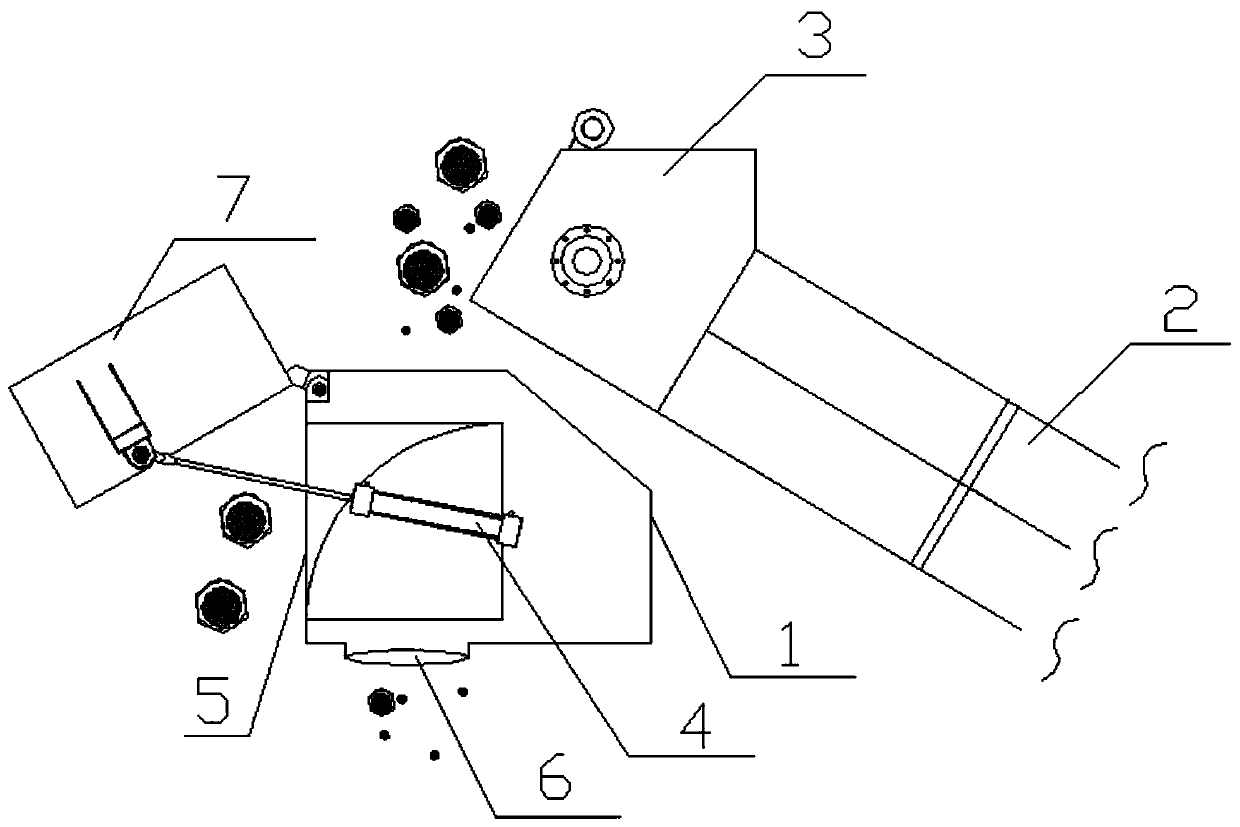

[0030] Such as Figures 1 to 2 As shown, the present invention provides a kind of equipment for sorting residues, comprising: a slag sorting device 1, which is provided with a slag inlet; the residue enters the slag sorting device 1 through the slag inlet; the residue includes fine slag and coarse slag; The inside of the slag sorting device 1 is provided with a plurality of grates 9, and the multiple grates 9 are evenly spaced; the fine slag outlet 6 is provided in the slag sorting device 1, and the fine slag leaves the slag from the fine slag outlet 6 through the gap between the grates 9 Device 1; sealing device 7, the sealing device 7 is arranged on the outside of the slag separating device 1 and connected with the slag separating device 1; the pneumatic device, the pneumatic device is respectively connected with the slag separating device 1 and the sealing device 7, and the pneumatic device is arranged on the slag separating device 1, the pneumatic device is used to control...

Embodiment 2

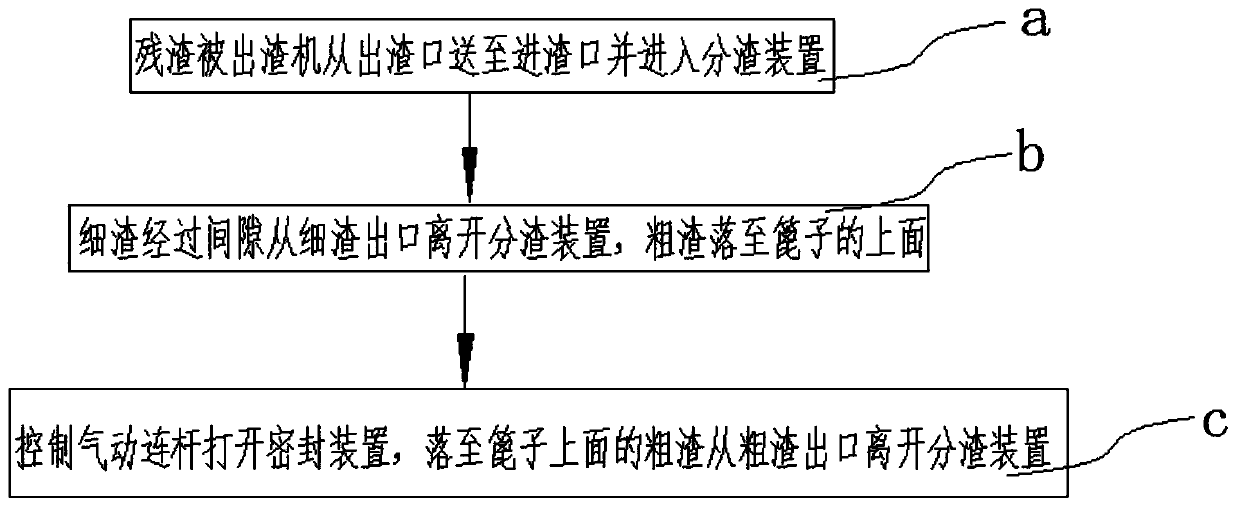

[0039] Such as image 3 Shown, the present invention provides a kind of method of sorting residue, comprises the steps:

[0040] a. Start the motor 10, the motor 10 drives the chain of the slag extractor 2 to rotate, and the chain drives the scraper at the bottom of the slag extractor 2 to move, and the residue at the bottom of the slag extractor 2 is sent from the slag outlet 8 to the slag inlet by the scraper. Enter the slag separator 1;

[0041] b. The fine slag leaves the slag sorting device 1 from the fine slag outlet 6 through the gap and is collected, and the coarse slag falls to the top of the grate 9;

[0042] c. Control the pneumatic connecting rod 4 to open the sealing device 7, and the coarse slag falling on the top of the grate 9 leaves the slag separating device 1 from the slag outlet and is collected; after the collection is completed, control the pneumatic connecting rod 4 to close the sealing device 7.

[0043] The method for sorting residues of the inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com