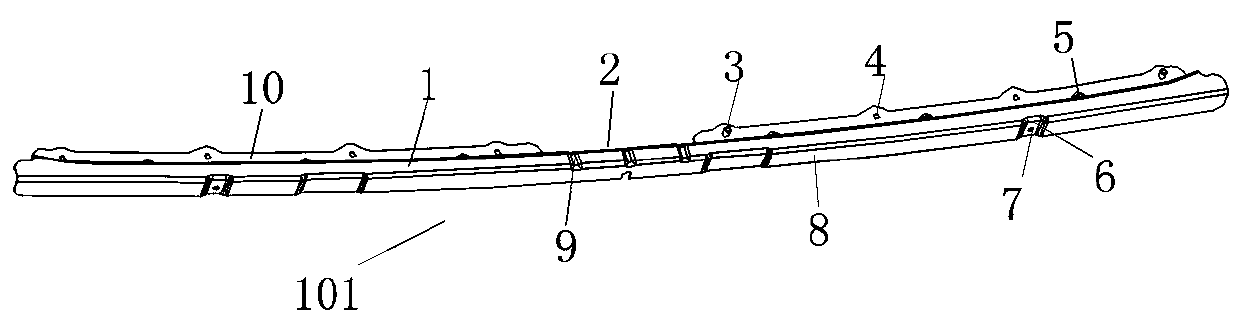

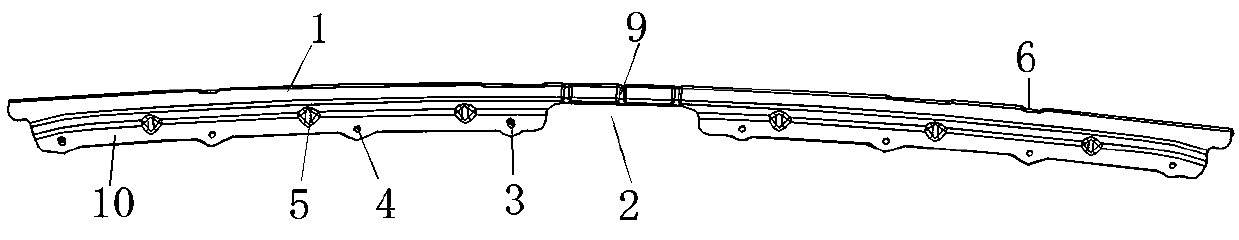

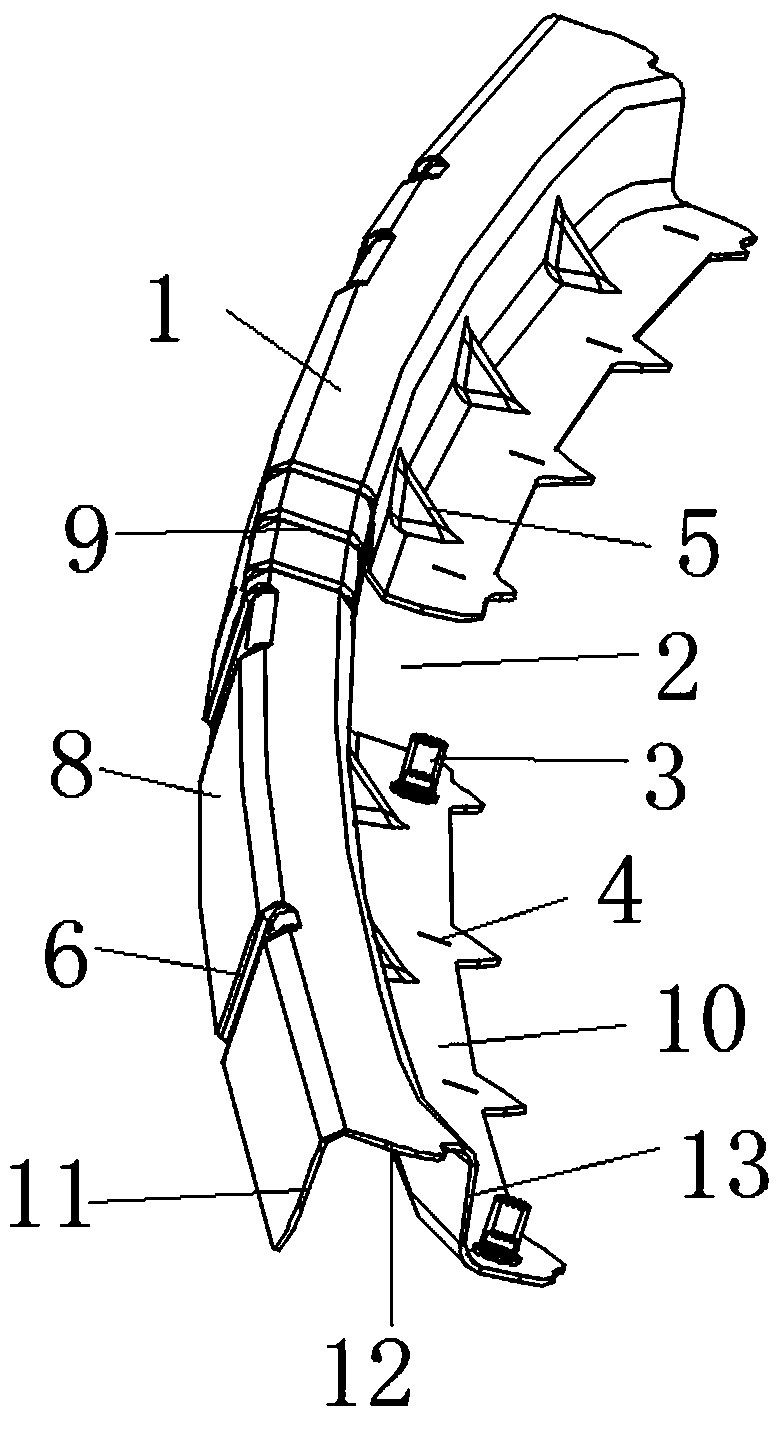

Front wall framework, fixing support of front wall framework and vehicle

A technology of cowl frame and fixing bracket, which is applied in the direction of vehicle parts, upper structure, upper structure sub-assembly, etc., can solve the problems of large amount of welding, difficult positioning, and single function of fixing bracket, so as to reduce welding amount and ensure Consistency, the effect of improving fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 9

[0056] The specific embodiment 9 of the cowl framework of the present invention, as a further optimization of the specific embodiment 8, in order to increase the strength of the position of the weight-reducing notch corresponding to the bottom plate, in this embodiment, the position of the bottom plate corresponding to the weight-reducing notch is provided with Bottom plate stiffeners. In other embodiments, no bottom plate reinforcing ribs may be provided.

[0057] The specific embodiment 10 of the cowl framework of the present invention, as a further optimization of the specific embodiment 5, in order to facilitate the installation of the front windshield, in this embodiment, the second hem and the windshield upper beam are arranged in a dislocation to form steps The front brim skin corresponding to the second flange and the upper beam of the windshield forms a positioning notch of the front windshield at the step.

[0058] The specific embodiment 11 of the cowl frame of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com