A gripping manipulator and a glove packaging machine

A technology of manipulators and packaging machines, which is applied in the directions of packaging, transportation, packaging, and strapping machine parts, etc. It can solve the problems of cumbersome grasping methods, inability to remove gloves, and reduce the efficiency of glove packaging, so as to avoid folding backlogs and improve Tolerance ratio and the effect of expanding the clamping position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

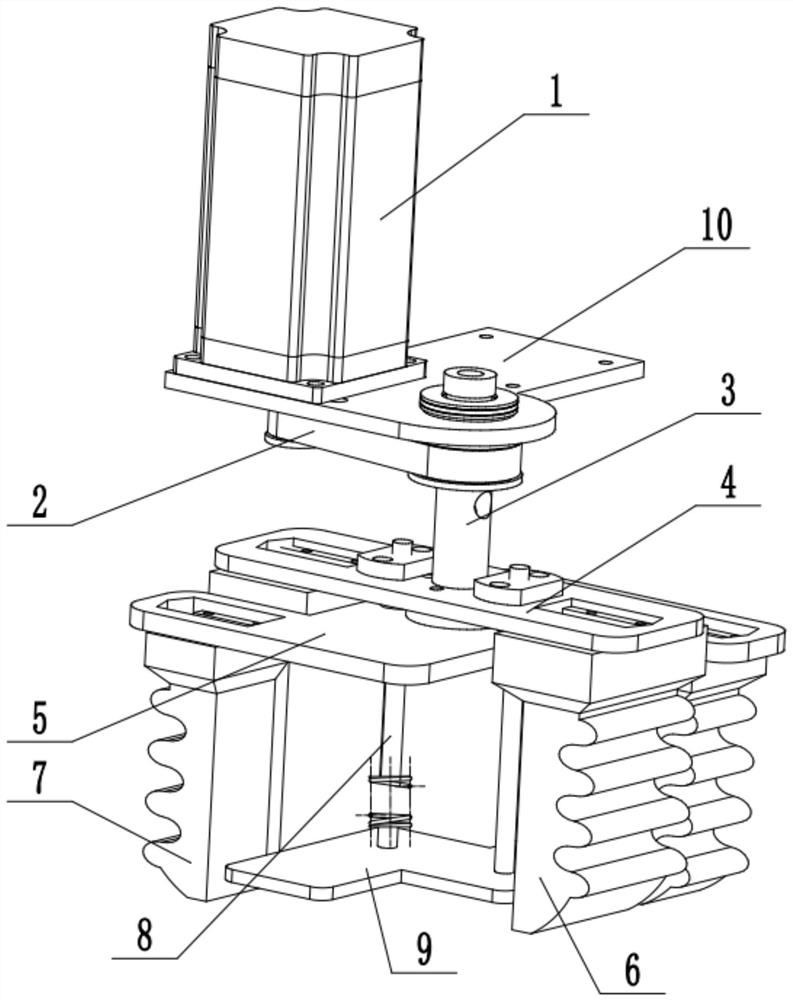

[0044] In a typical embodiment of the application, such as Figure 1 A clamping manipulator for glove packaging machine is proposed.

[0045] The utility model comprises a fourth plate 10, the first plate is used for docking the mechanical arm, and a rotating shaft 3 is installed on it through a bearing, the rotating shaft is connected with the fourth stepping motor 1 through a transmission structure, the other end of the rotating shaft is connected with a support plate 4, the support plate is provided with a through hole, a sliding rod 8 is matched in the through hole, one end of the sliding rod is connected with a positioning plate 9, and both ends of the support plate are respectively equipped with soft fingers 6, The fourth stepping motor drives the rotating shaft to rotate through the transmission structure 2, so as to drive the support plate and the structure installed on the support plate to rotate together. The soft finger includes an air bag and a contact plate. The air ba...

Embodiment 2

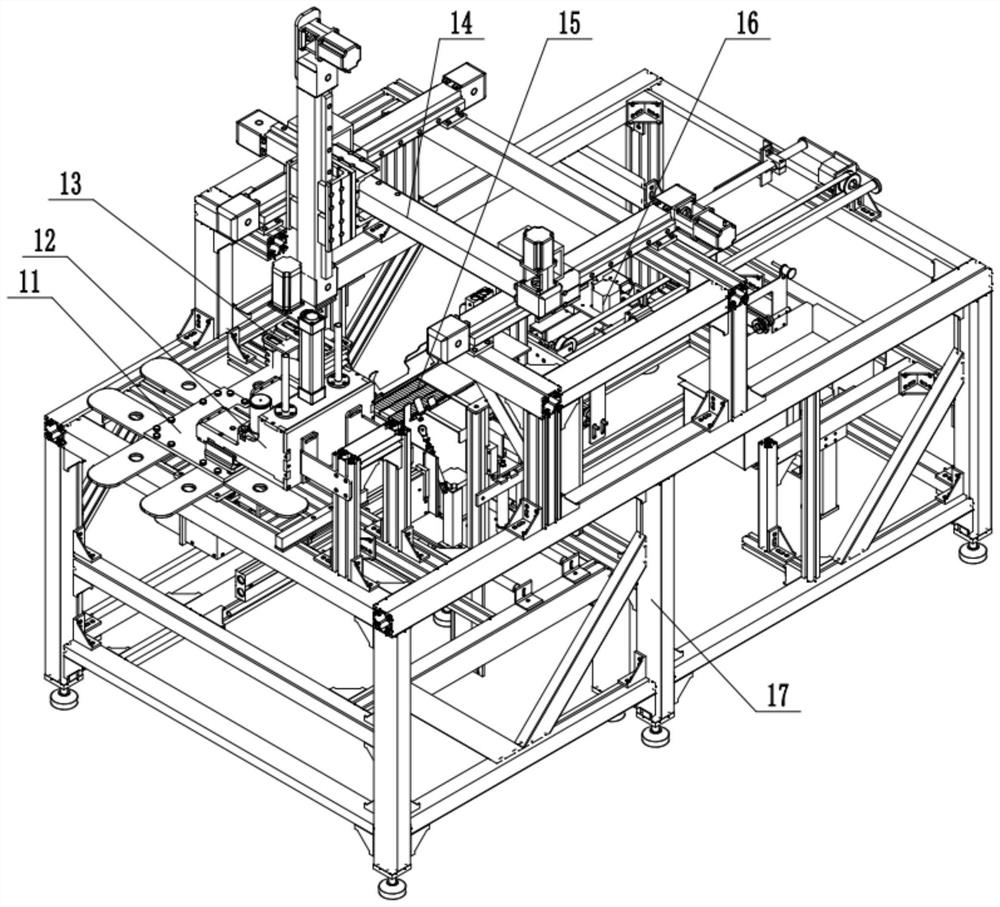

[0055] In another exemplary embodiment of the invention, such as Figure 1 - Figure 7 As shown in the figure, a glove packaging machine using the clamping manipulator in embodiment 1 is provided.

[0056] The glove packaging machine comprises:

[0057] A rotary table device for conveying gloves to the clamping station in pairs through the rotary table;

[0058] The baling device is used to receive pairs of gloves and transport them to the bagging station after being compressed;

[0059] The gripping device comprises a mechanical arm with three degrees of freedom, the end of the mechanical arm is equipped with a gripping manipulator, and the mechanical arm drives the gripping manipulator to grab gloves from the gripping station and transport them to the baling device;

[0060] The bagging device is used to receive the gloves of the bagging station and put them into the packaging bag.

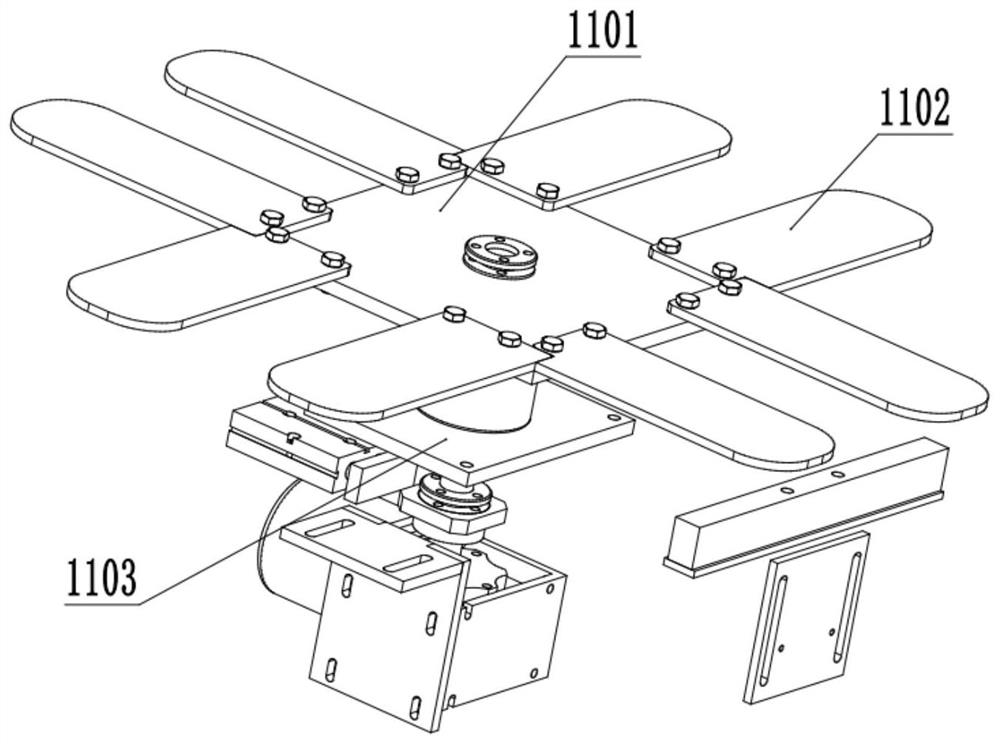

[0061] The rotary table device includes a rectangular rotary table 1101, which is driven to rotate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap