Yarn waxing device and yarn waxing method

A yarn and candle technology, applied in the field of yarn waxing processing equipment, can solve problems such as complex structure, achieve fluffy effect, improve softness, and reduce failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

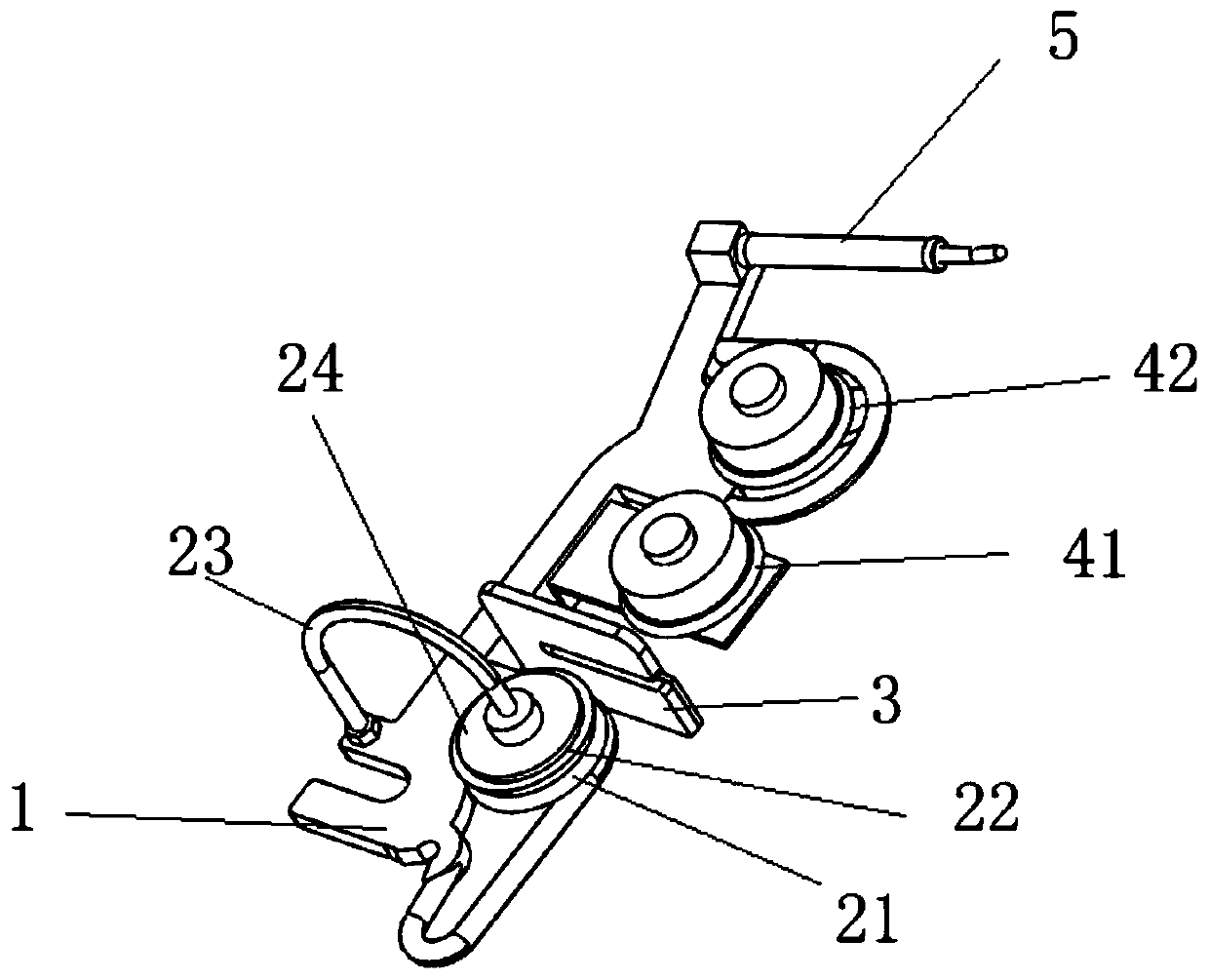

[0048] This embodiment provides a yarn waxing device, such as figure 1 shown, including:

[0049] Rack 1,

[0050] The lower pressure roller 21 and the upper pressure roller 22, the lower pressure roller 21 and the upper pressure roller 22 are coaxially arranged and arranged on the frame 1 to be able to rotate freely in the horizontal direction, and the yarn passes through the lower pressure roller 21 and the upper pressure roller 22 and is pressed by the upper pressure roller 22;

[0051] Knife door 3, the middle of the knife door 3 has a knife edge through which the yarn passes;

[0052] a candle mounting post, at least one, for holding a column-shaped wax post;

[0053] Lead rods are arranged on the frame 1 along the horizontal direction.

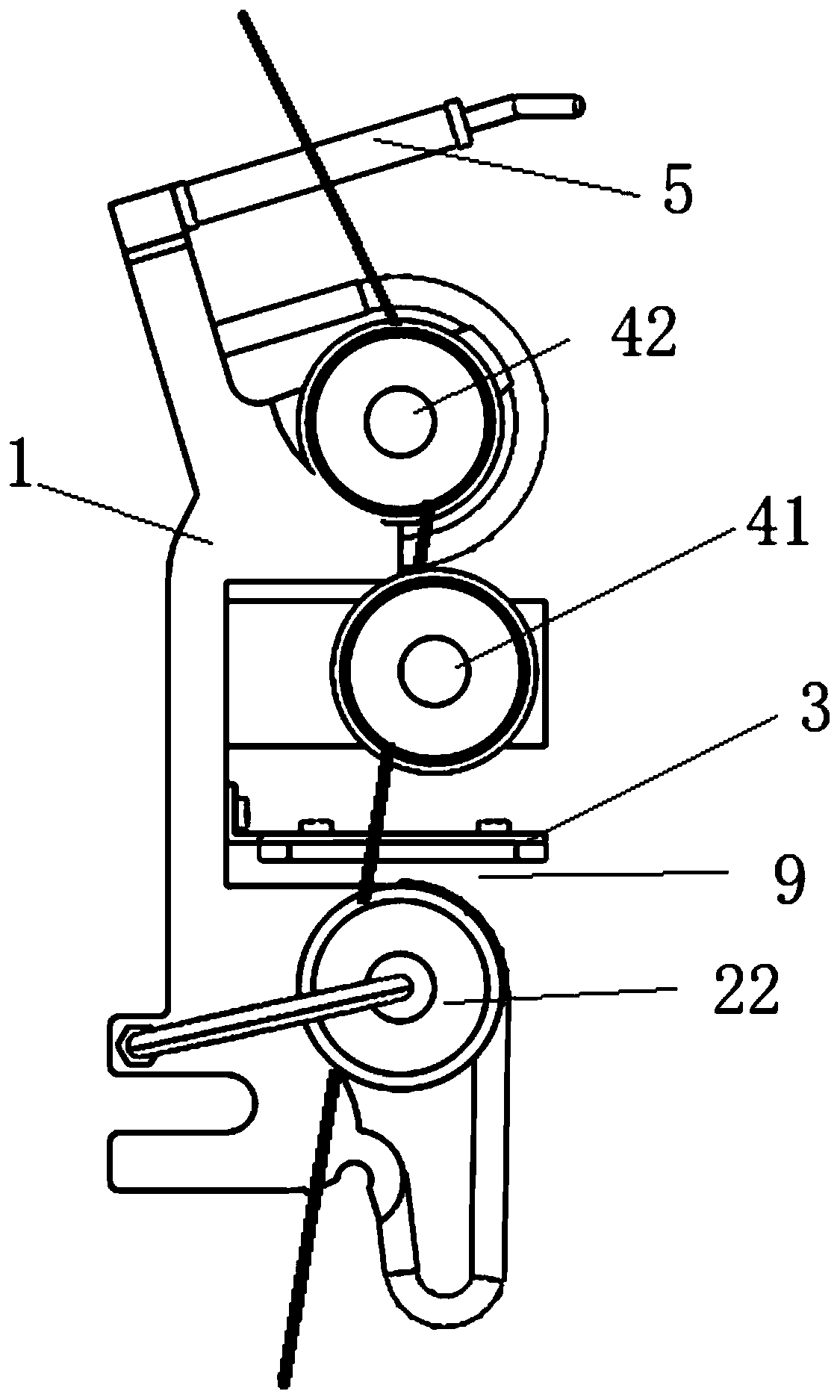

[0054] When the above-mentioned yarn waxing device is used, as figure 2 As shown, the yarn 9 is sequentially passed between the lower pressing wheel 21 and the upper pressing wheel 22, the knife edge of the knife door 3, and the wa...

Embodiment 2

[0064] This embodiment provides a method for waxing yarns,

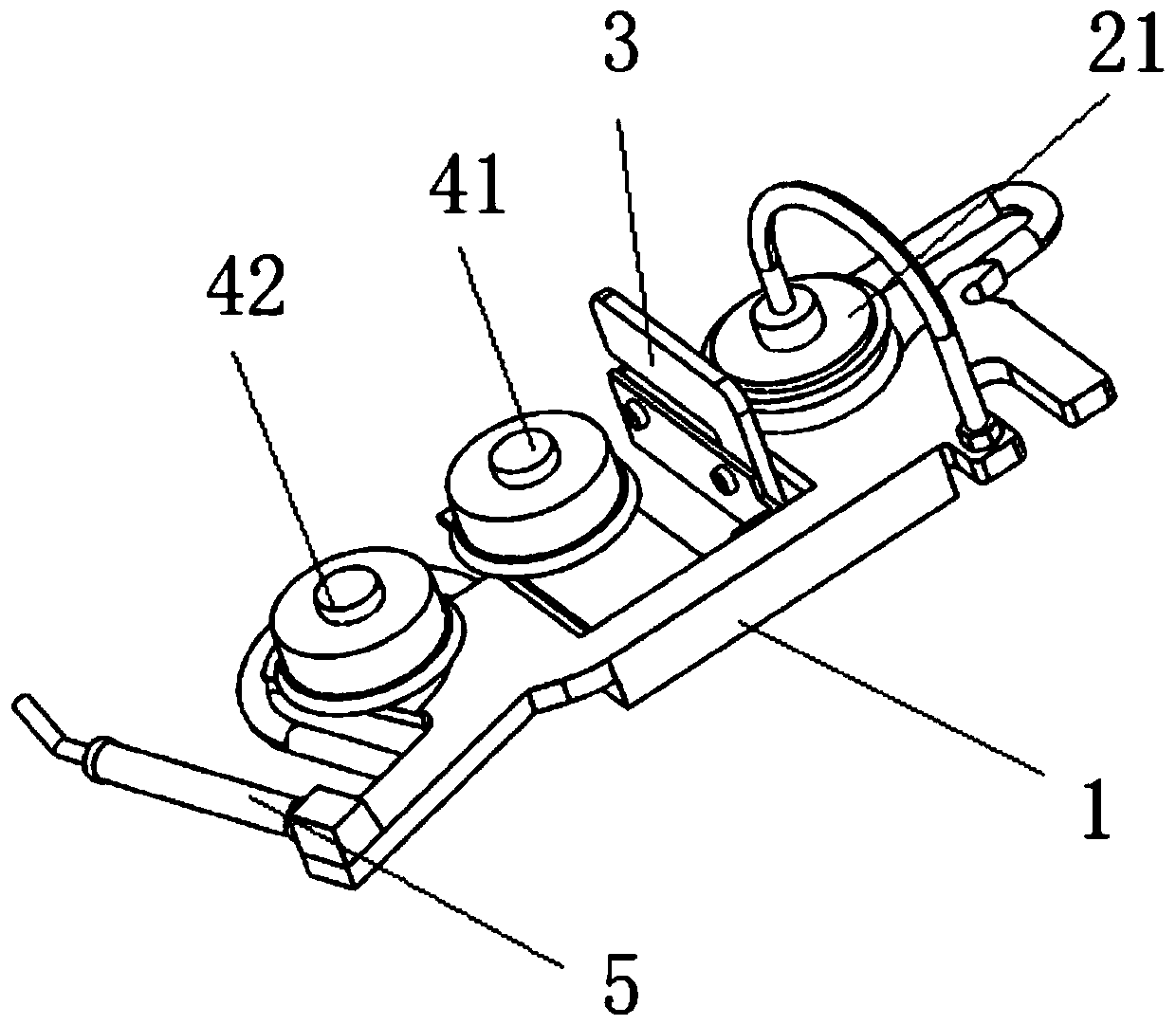

[0065] Use a yarn waxing device with two candle installation posts, the two candle installation posts are respectively the first installation post 41 and the second installation post 42, and the first installation post 41 and the second installation post 42 are respectively placed with 6-10cm wax column, the gap or the diameter of the edge of the knife door 3 is set to 10-20 times the yarn diameter;

[0066] Include the following steps:

[0067] Pass the yarn 9 sequentially between the lower pressing wheel 21 and the upper pressing wheel 22, the knife edge of the knife door 3, and the wax column on the candle installation column, and the yarn is twitched by external force, so that the yarn flows out of the yarn through the guide rod for waxing When the yarn is installed, the yarn passes through both sides of the first installation column 41 and the second installation column 42 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com