A tib for aluminum electrolysis 2 -Graphene composite cathode material and preparation method thereof

A graphene composite and cathode material technology, which is applied to the TiB2-graphene composite wettable cathode material for aluminum electrolysis and its preparation, and the TiB2-graphene composite cathode material for aluminum electrolysis and its preparation field, which can solve the problem of coating Low bonding strength with the substrate, poor thermal shock resistance of coating materials, uneven thermal expansion coefficient, etc., to achieve good resistance to high temperature molten salt erosion, good compactness, and easy to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

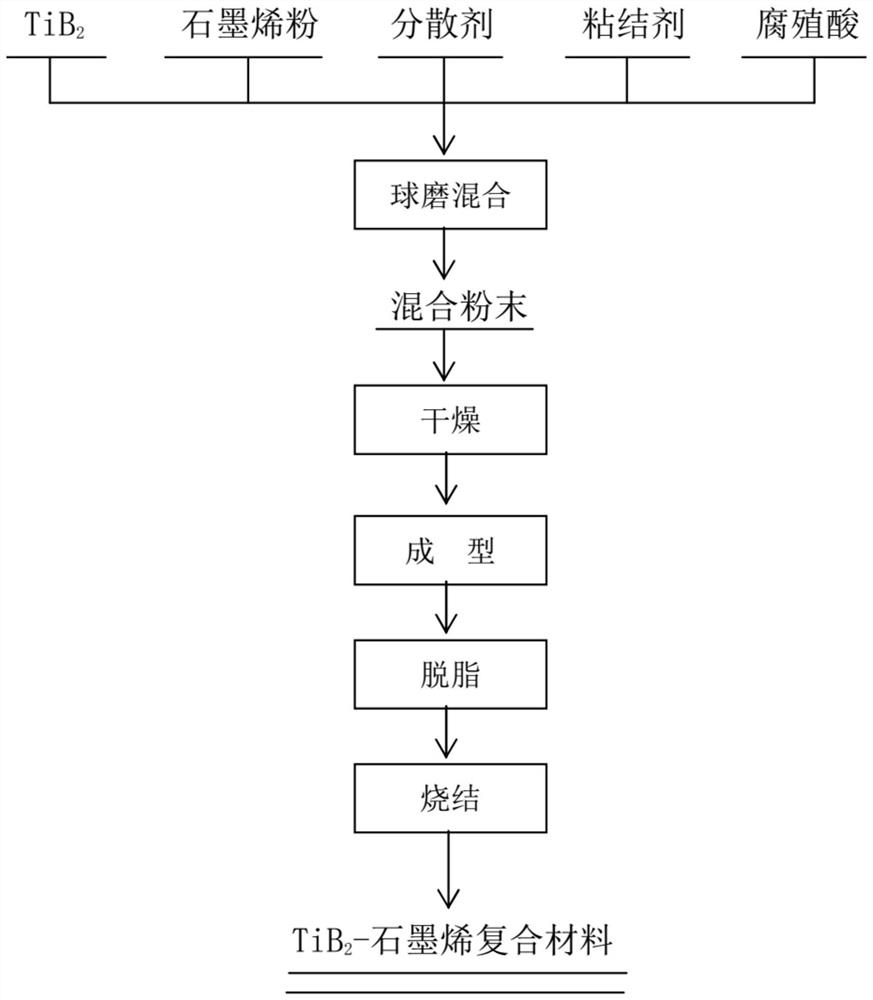

Method used

Image

Examples

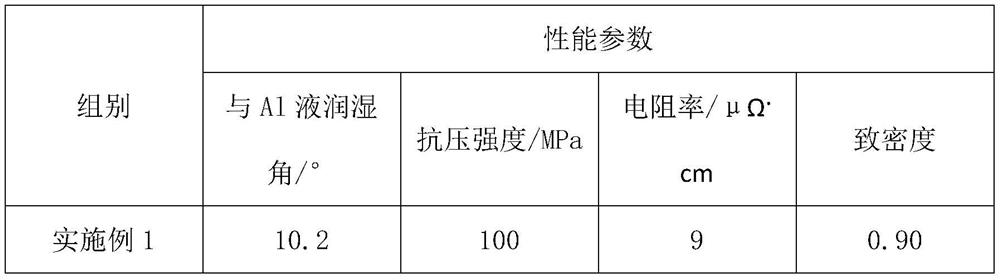

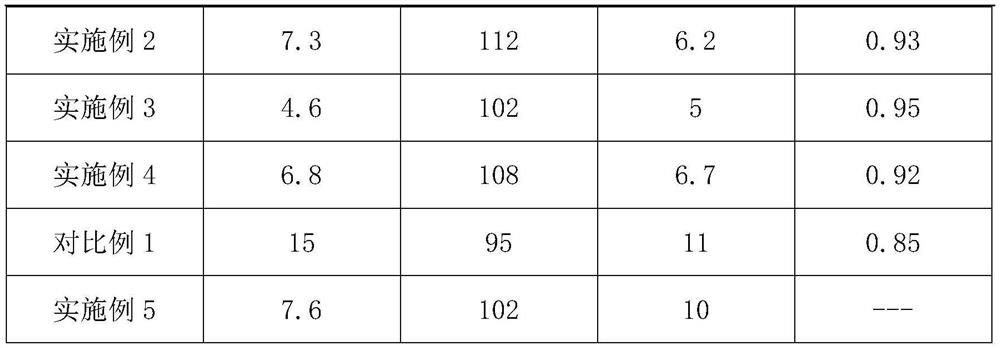

Embodiment 1

[0033] 95gTiB 2 Powder, 5g of graphene powder, 1g of water, 2g of epoxy resin and 1g of humic acid were mixed by ball mill for 4h, dried at 100°C for 10h, and subjected to vibration molding under a pressure of 200MPa to obtain TiB 2 - Graphene composite material green body, put the green body in an electric furnace, and perform degreasing treatment in an inert protective atmosphere, the degreasing temperature is 600 ° C, the degreasing time is 64h, and the oxygen content in the atmosphere is 50ppm; then in the Ar protective atmosphere The sintering process was carried out at a temperature of 50 °C / h to 1600 °C for sintering, and the temperature was kept for 5 h. During the sintering process, O 2 The content of TiB is 1ppm, and the sintering pressure is 2 tons; that is, TiB 2 - Graphene composite cathode material.

Embodiment 2

[0035] 60gTiB 2Powder, 40g graphene powder, 2g alcohol, 3g phenolic resin and 5g humic acid were mixed by ball mill for 6h, dried at 110°C for 10h, and vibrated under a pressure of 300MPa to obtain TiB 2 - Graphene composite green body, put the green body in an electric furnace, degrease in an inert protective atmosphere, the degreasing temperature is 800 ° C, the degreasing time is 48h, and the oxygen content in the atmosphere is 30ppm; then in the Ar protective atmosphere The sintering process was carried out at a temperature of 50 °C / h to 1500 °C for sintering, and the temperature was kept for 20 h. During the sintering process, O 2 The content of TiB is 5ppm, and the sintering pressure is 3 tons; that is, TiB 2 - Graphene composite cathode material.

Embodiment 3

[0037] 30gTiB 2 Powder, 70g of graphene powder, 5g of phthalic acid, 5g of polyethylene ethyl ester and 10g of humic acid were mixed by ball mill for 4 hours, dried at 100°C for 10 hours, and subjected to vibration molding under a pressure of 200MPa to obtain TiB 2 - Graphene composite material green body, put the green body in an electric furnace, degrease in an inert protective atmosphere, the degreasing temperature is 900 ° C, the degreasing time is 64h, and the oxygen content in the atmosphere is 10ppm; The sintering process was carried out at a temperature of 50°C / h to 1300°C for sintering, and the temperature was kept for 40h. During the sintering process, O 2 The content of TiB is 10ppm, and the sintering pressure is 4 tons; that is, TiB 2 - Graphene composite cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com