Paper faced gypsum board suspended ceiling construction technology

A paper-faced gypsum board and construction technology technology, applied in the direction of ceilings, building components, buildings, etc., can solve problems such as affecting the overall ceiling flatness and visual effect, the quality of construction cannot be guaranteed, falling off or loosening, etc., so as to improve the overall Flatness and look and feel, improved accuracy and installation efficiency, the effect of high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

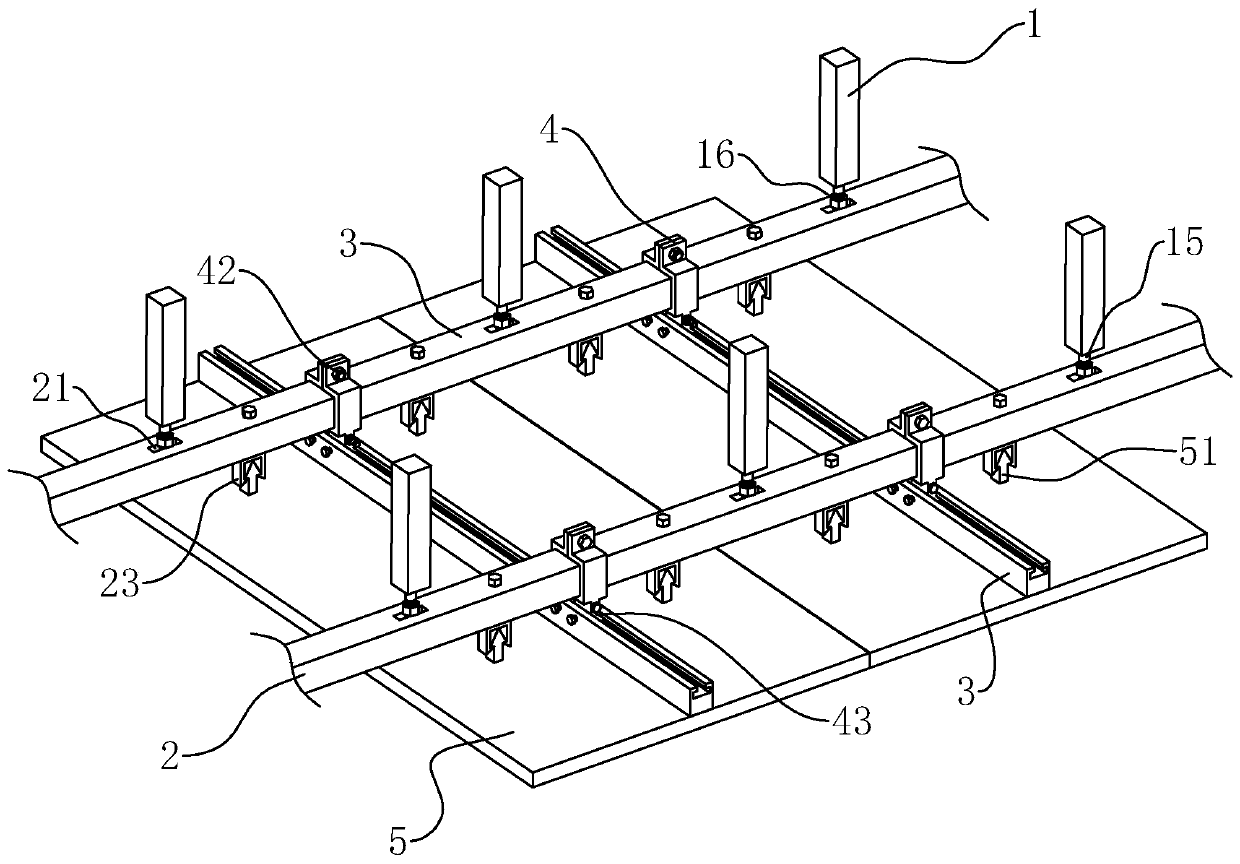

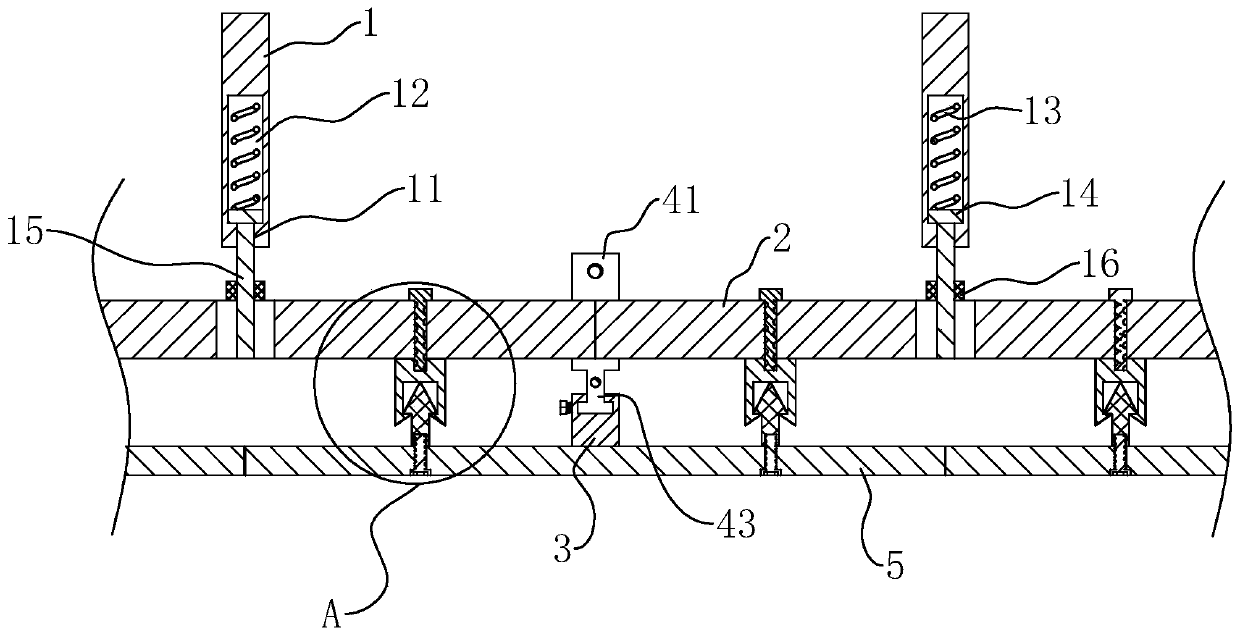

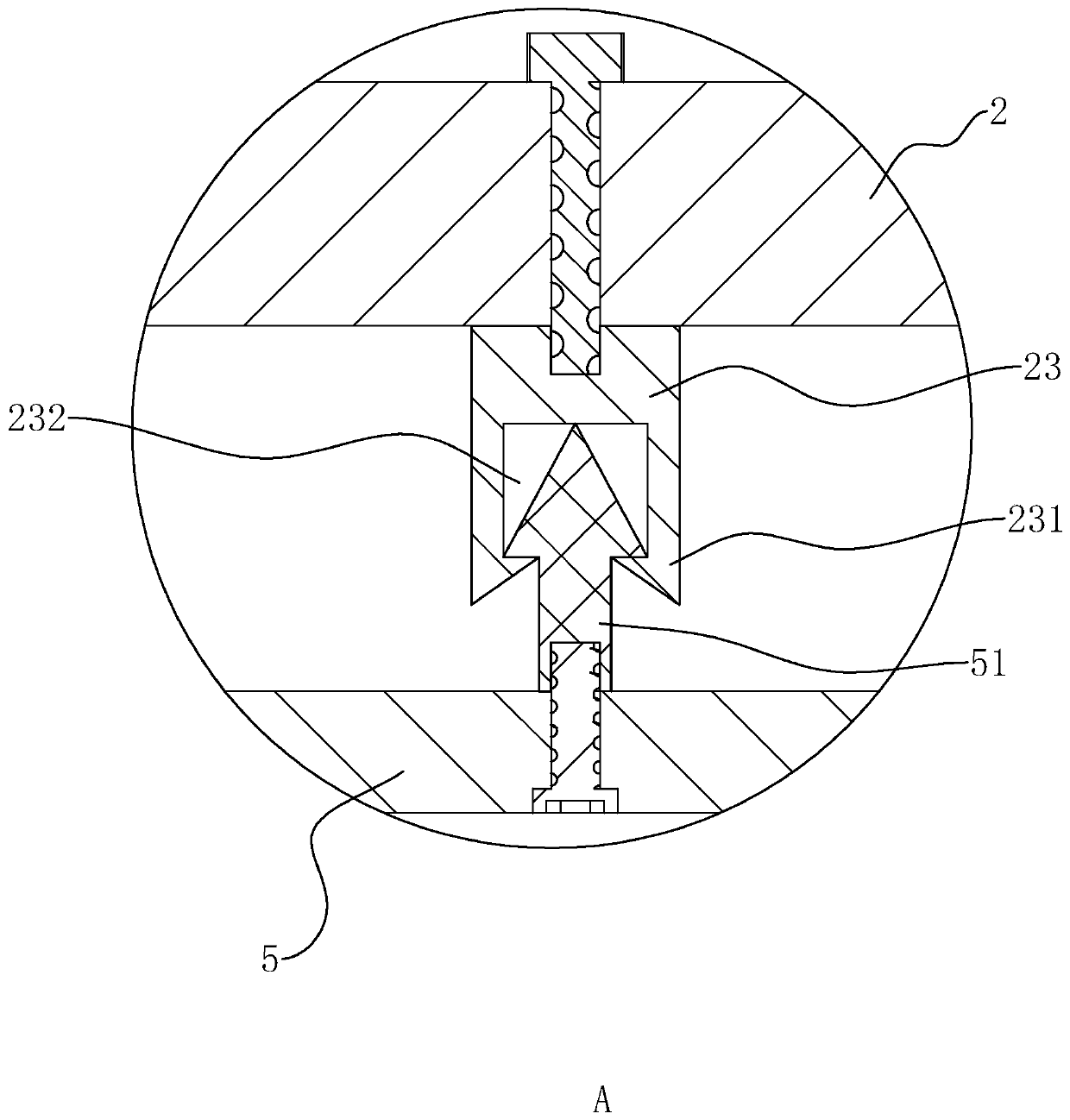

[0037] The construction technology of the gypsum board suspended ceiling will be further explained with reference to the accompanying drawings.

[0038] A kind of construction technology of plaster board suspended ceiling, comprises the following steps:

[0039] S1. Measure the spring line: according to the floor elevation reference line, the ceiling elevation horizontal line is projected along the wall, and the keel classification position line is drawn on the wall along the horizontal line, and the keel position line is led to the base layer of the top floor.

[0040] S2. Suspender installation: According to the design requirements and national regulations, determine the distance between the keel suspender 1 along the position line of the main keel 2, determine the position, drill holes at the base of the floor with an electric drill, and fix the keel suspender 1 to the building with expansion bolts superior.

[0041] S3. Install the main keel: combine figure 1 As shown, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com