Energy-saving and environment-friendly cooling and dehumidifying system and method for metal mold production line

A technology of cooling and dehumidification, metal molds, applied in air conditioning systems, heating methods, household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

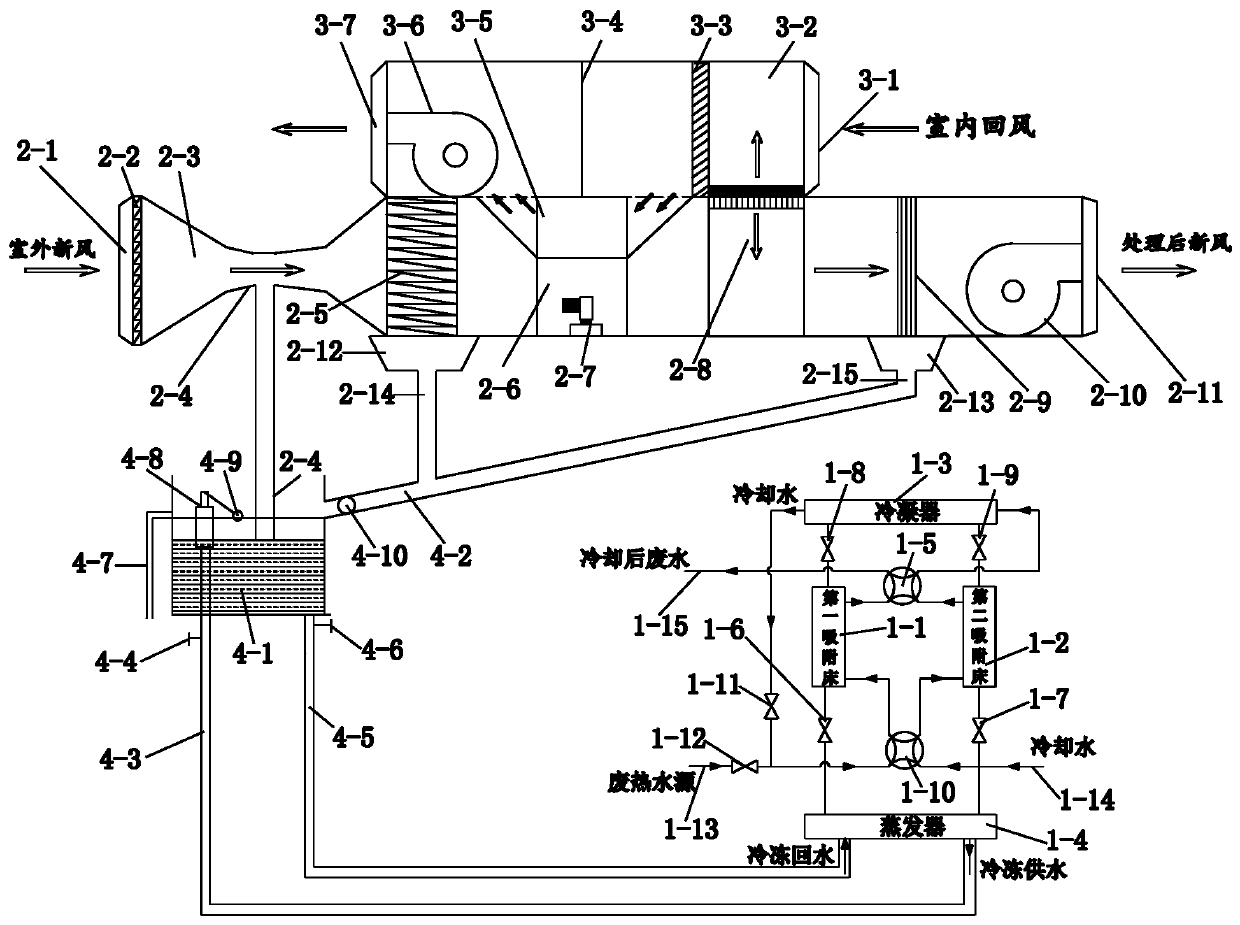

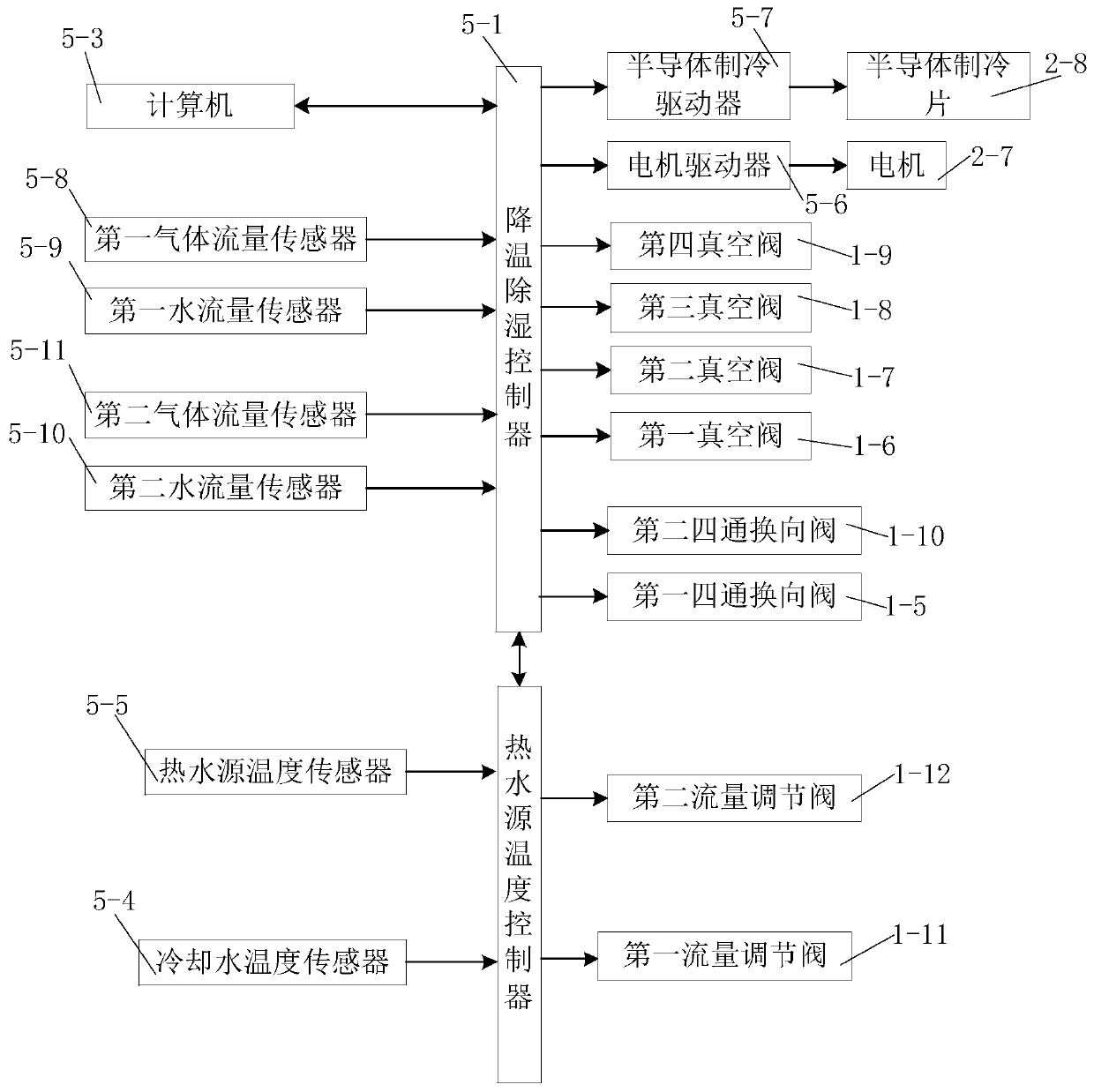

[0100] Such as figure 1 As shown, the energy-saving and environment-friendly metal mold production line cooling and dehumidification system of the present invention includes an adsorption refrigeration system, a pumpless cooling and dehumidification purification system, a runner dehumidification regeneration system and an automatic water replenishment system, and the runner dehumidification regeneration system is arranged in a pumpless The top of the cooling and dehumidification purification system;

[0101] The adsorption refrigeration system includes a first adsorption bed 1-1, a second adsorption bed 1-2, a condenser 1-3, an evaporator 1-4, a first four-way reversing valve 1-5, a second four-way Reversing valve 1-10, first vacuum valve 1-6, second vacuum valve 1-7, third vacuum valve 1-8, fourth vacuum valve 1-9, first flow regulating valve 1-11 and second A flow regulating valve 1-12, the first adsorption bed 1-1 and the second adsorption bed 1-2 are arranged side by side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com