Method and device for automatically determining steady state of truck scale

A stable state, automatic judgment technology, applied in the direction of measuring devices, optical device exploration, optical devices, etc., can solve the problems of time-consuming and manpower, and the accuracy of measurement data cannot be guaranteed, so as to ensure the accuracy of the position and avoid weighing The effect of cheating and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

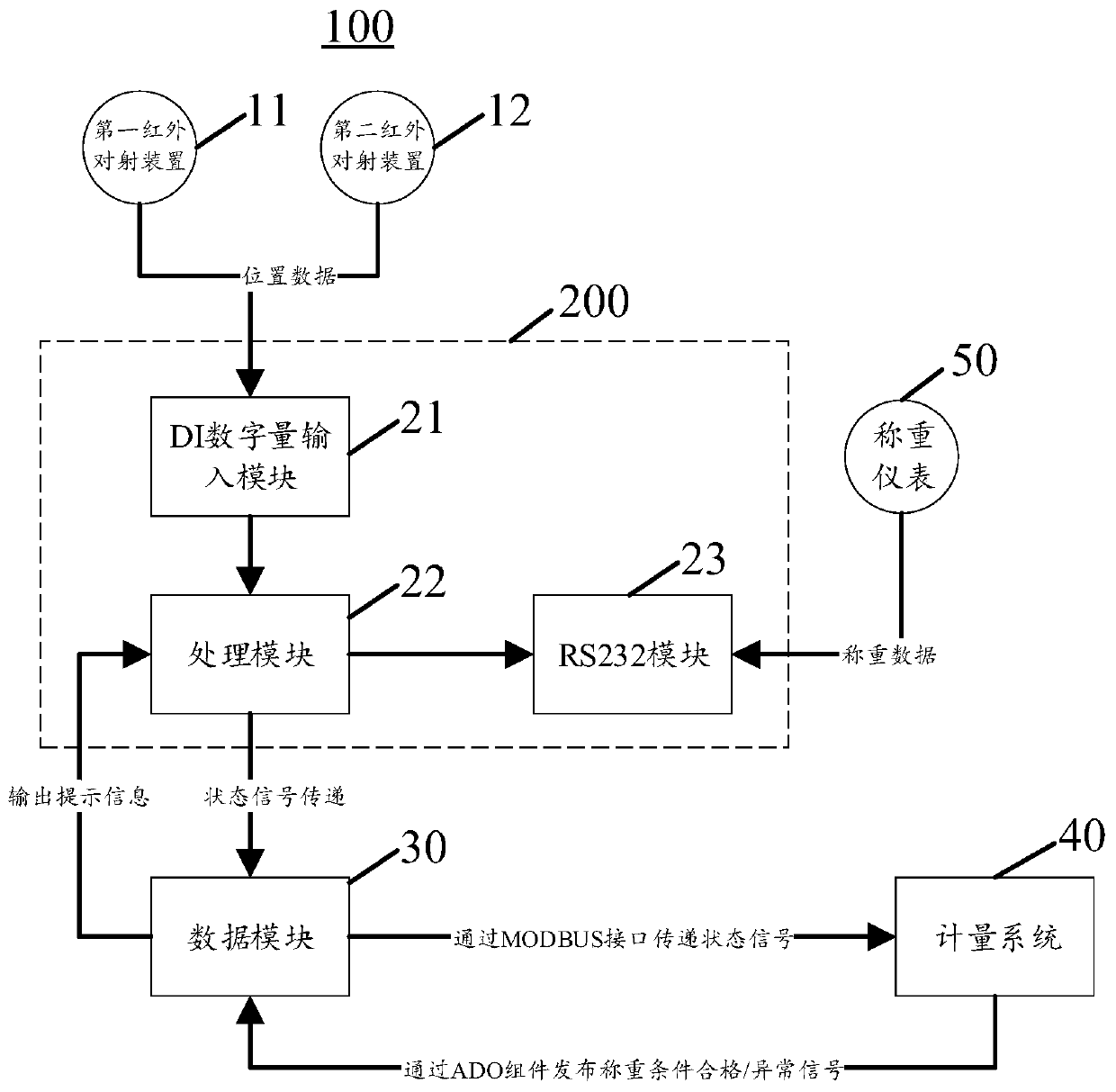

[0037] Please refer to figure 1, In this embodiment, a truck scale stable state automatic judgment device 100 is provided. The device includes: a position detection module, a weighing module, a PLC module 200 , a data module 30 and a metering system 40 .

[0038] The position detection module is used to monitor the position data of the target vehicle on the truck scale, which can be set at the upper scale position and the lower scale position of the truck scale; The radar performs position detection without limitation.

[0039] Specifically, the position detection module may include: a first infrared radiation device 11, installed on both sides of the front of the truck scale, for detecting whether there is a block in front of the truck scale, and obtaining first position data; The shooting device 12 is installed on both sides of the rear of the truck scale, and is used to detect whether there is an obstruction at the rear of the truck scale, and obtain second position data. ...

no. 2 example

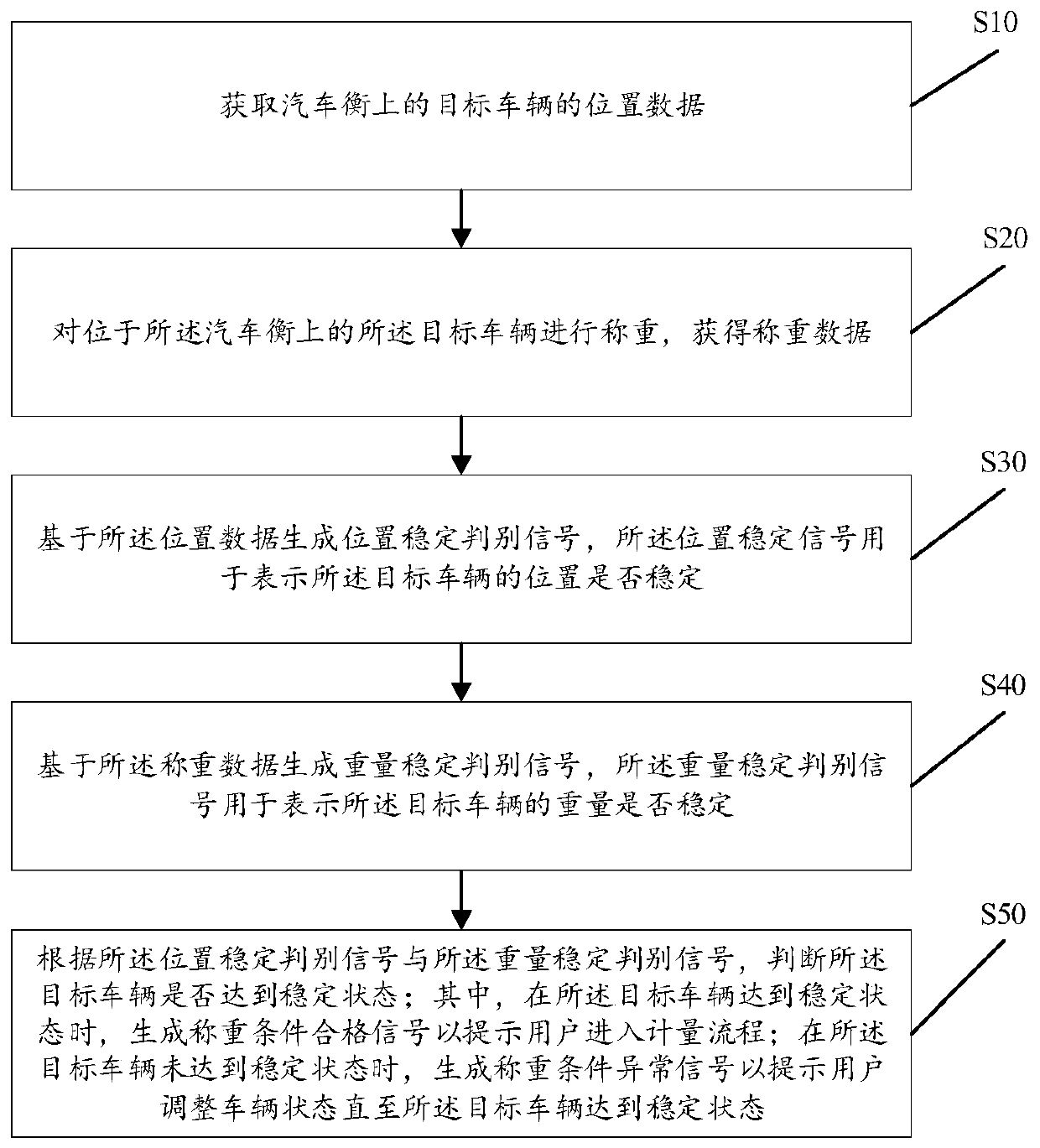

[0061] see image 3 , In this embodiment, a method for automatically judging the stable state of a truck scale is provided, which can be applied to the device described in the first embodiment, and the method includes:

[0062] Step S10: Obtain the position data of the target vehicle on the truck scale;

[0063] Step S20: weighing the target vehicle on the truck scale to obtain weighing data;

[0064] Step S30: generating a position stability discrimination signal based on the position data, the position stability signal is used to indicate whether the position of the target vehicle is stable;

[0065] Step S40: generating a weight stability discrimination signal based on the weighing data, and the weight stability discrimination signal is used to indicate whether the weight of the target vehicle is stable;

[0066] Step S50: According to the position stability determination signal and the weight stability determination signal, determine whether the target vehicle has reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com