Method for realizing fine analysis of iron ore sintering simulation test through process pause

A technology for simulating test and test process, applied in the field of iron ore powder agglomeration, it can solve the problems of large test error, small effect, waste of manpower and material resources, etc., and achieve the effect of reducing the amount of test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

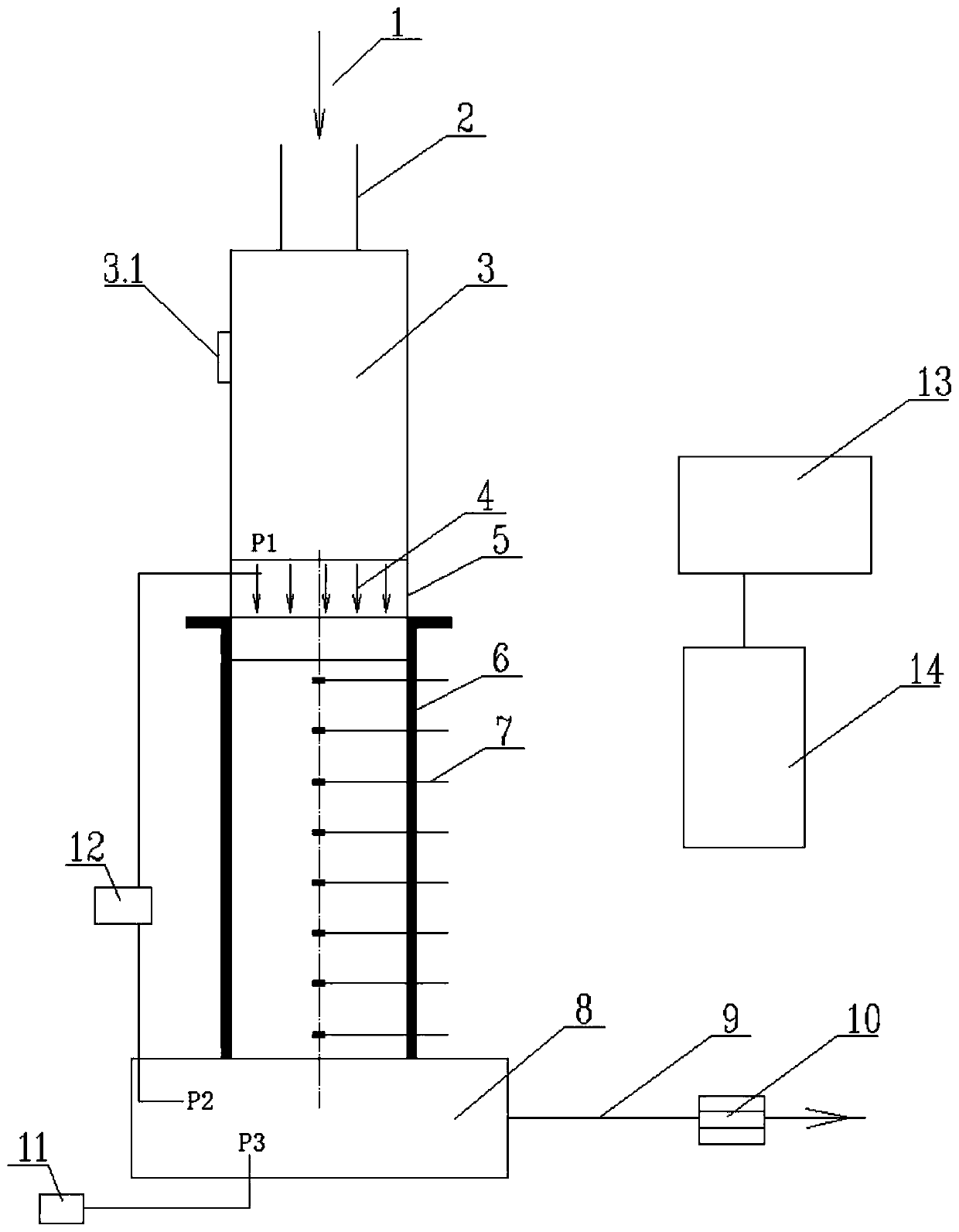

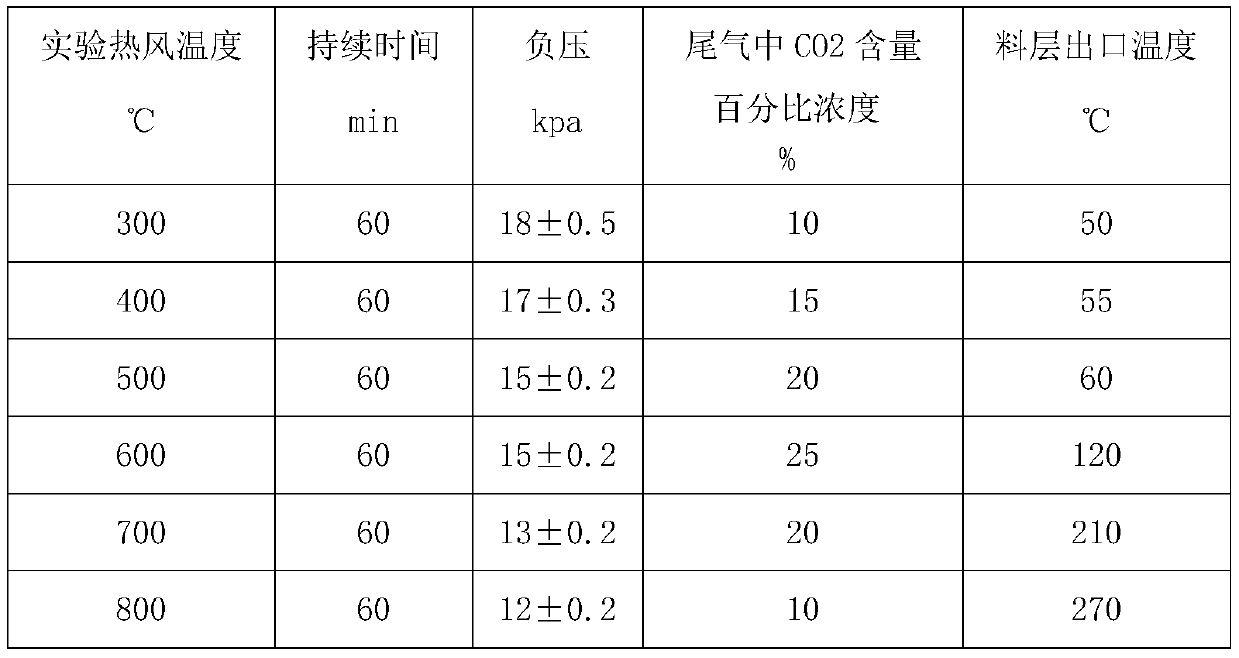

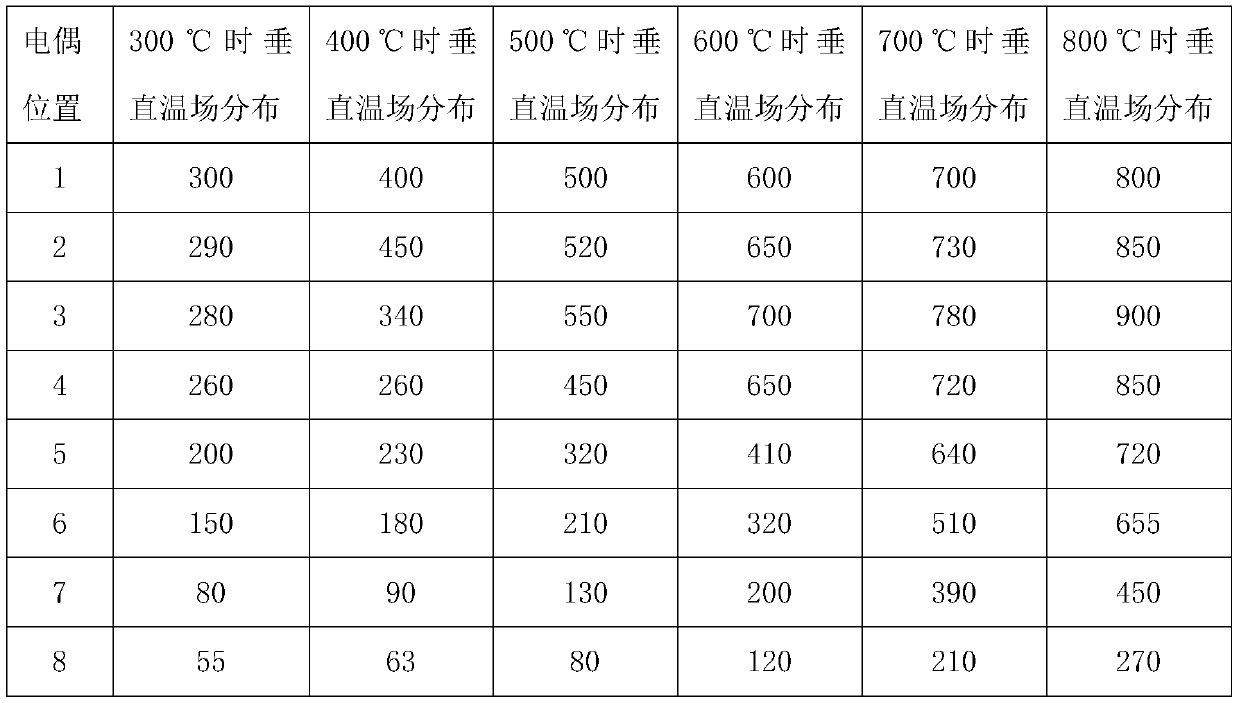

[0036] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0037] According to the invention, a method for fine analysis of iron ore sintering simulation test is realized by process pause. During the test process of the sample material before sintering, the stages of the process are realized through different process conditions, and the process is realized at a certain stage. Pause the sintering process and conduct qualitative analysis for this stage; analyze and adjust the final sintering scheme according to the process parameters and intermediate results of each stage.

[0038] Described process parameter specifically comprises:

[0039] 1) The process change of the moisture content of the material under different temperature conditions affects the air permeability and the temperature of the material layer section;

[0040] 2) Changes in the fusion characteristics of the added flux or other elemental c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com