Spraying arm assembly of dish-washing machine

A technology of spray arm assembly and dishwasher, which is applied to the parts of dishwashing machine/rinsing machine, dishwashing machine/washing machine, cleaning equipment, etc., can solve the problem that the driving force of the spray arm becomes smaller and the washing time is prolonged. , waste of resources and other problems, to achieve the effect of avoiding spray surface design, saving washing time, and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A preferred embodiment of the present invention will be described below with reference to the accompanying drawings.

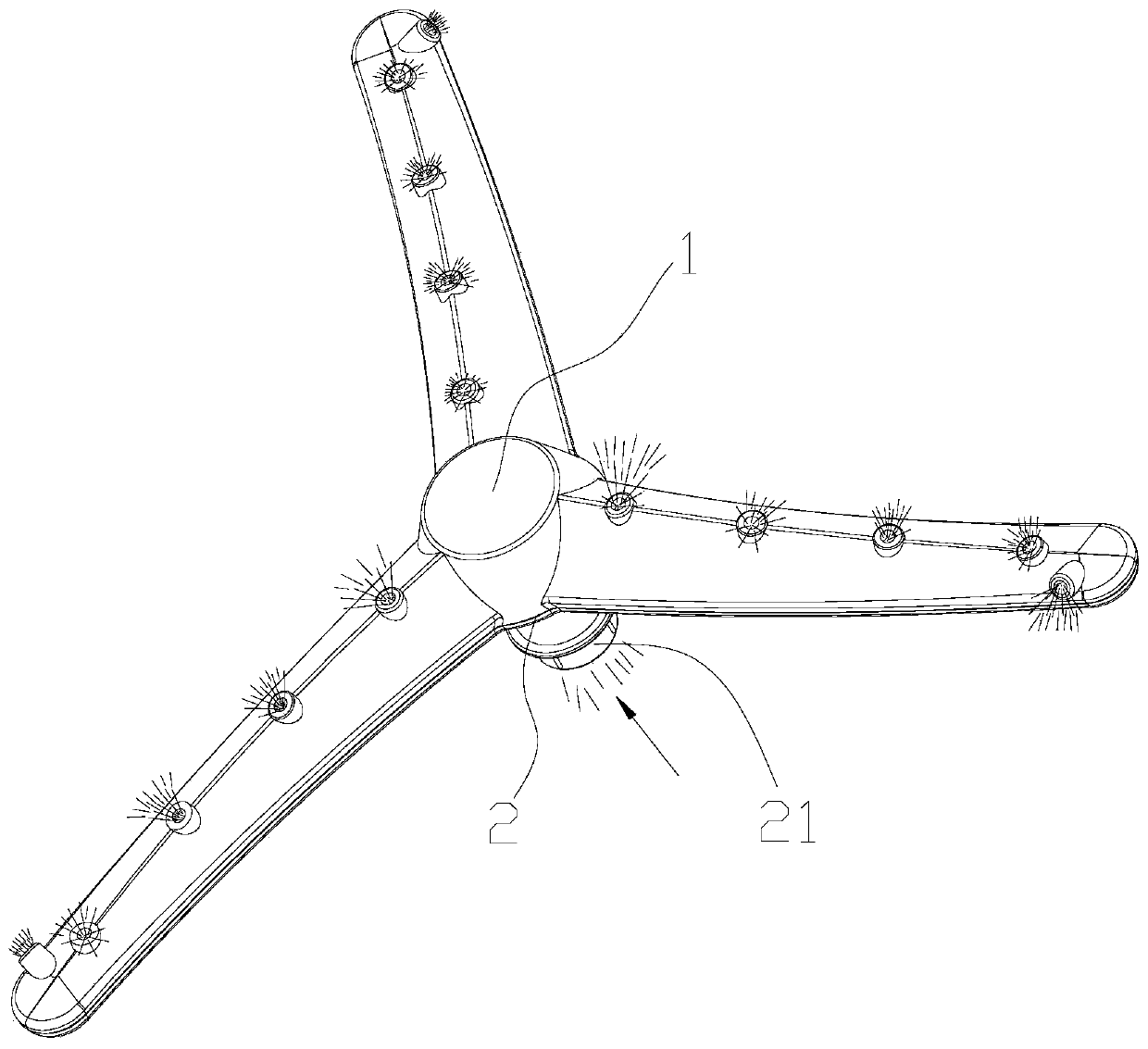

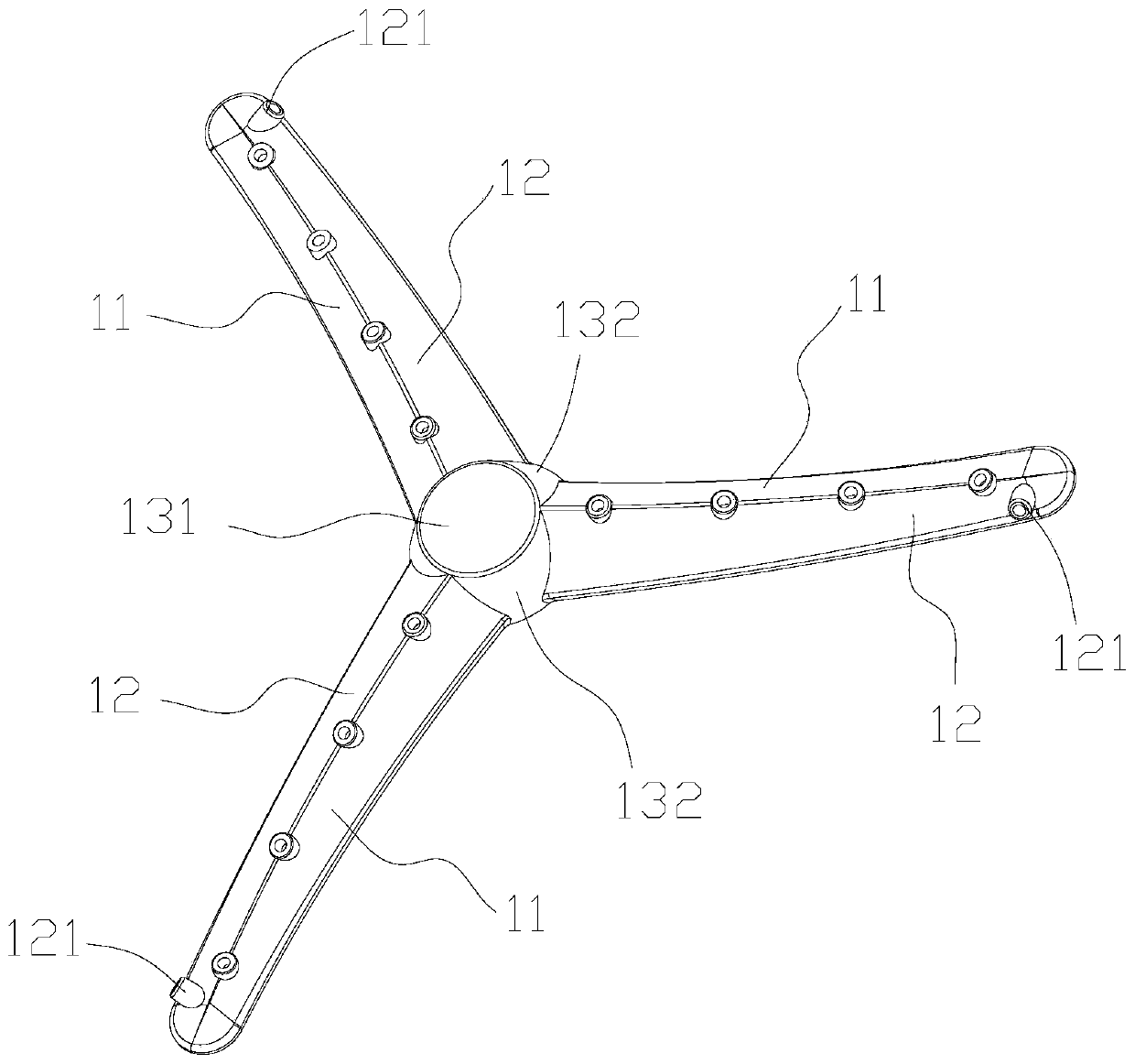

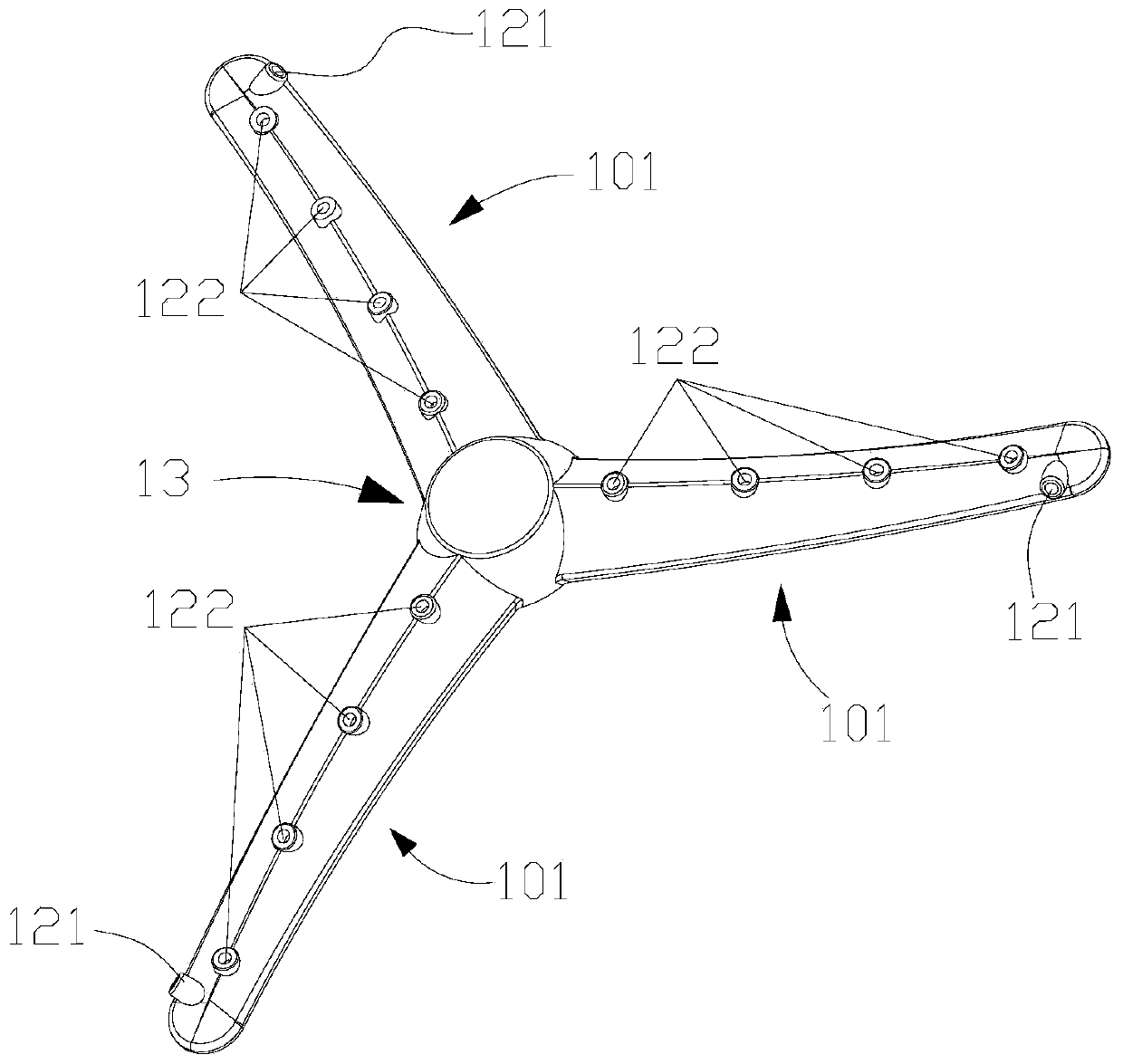

[0030] see Figure 1 to Figure 10 , a spray arm assembly of a dishwasher, the spray arm assembly includes an upper spray arm group 1 and a lower spray arm group 2, the middle part of the lower spray arm group 2 is provided with a guide tube 21, and the upper spray arm group 1 and the lower spray arm group 2 are connected to form a spray arm water collection chamber (not shown in the figure), and the spray arm water collection chamber communicates with the guide pipe 21, and the upper spray arm group 1 includes a connecting piece 13 and three The upper spray arm 101, the three upper spray arms 101 are arranged around the connecting piece 13, and the three upper spray arms 101 are arranged symmetrically to each other, and the upper spray arm 101 includes a thrust surface 12 and a suction surface 11 connected to each other , the connecting piece 13 is con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap