Air-filled ultrasonic transducer

An ultrasonic transducer and air technology, which is applied in ultrasonic/sonic/infrasonic diagnosis, acoustic diagnosis, infrasonic diagnosis, etc., can solve the problems of complex production process of ultrasonic transducer and high difficulty of thin film material process, so as to reduce dependence and simplify The effect of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

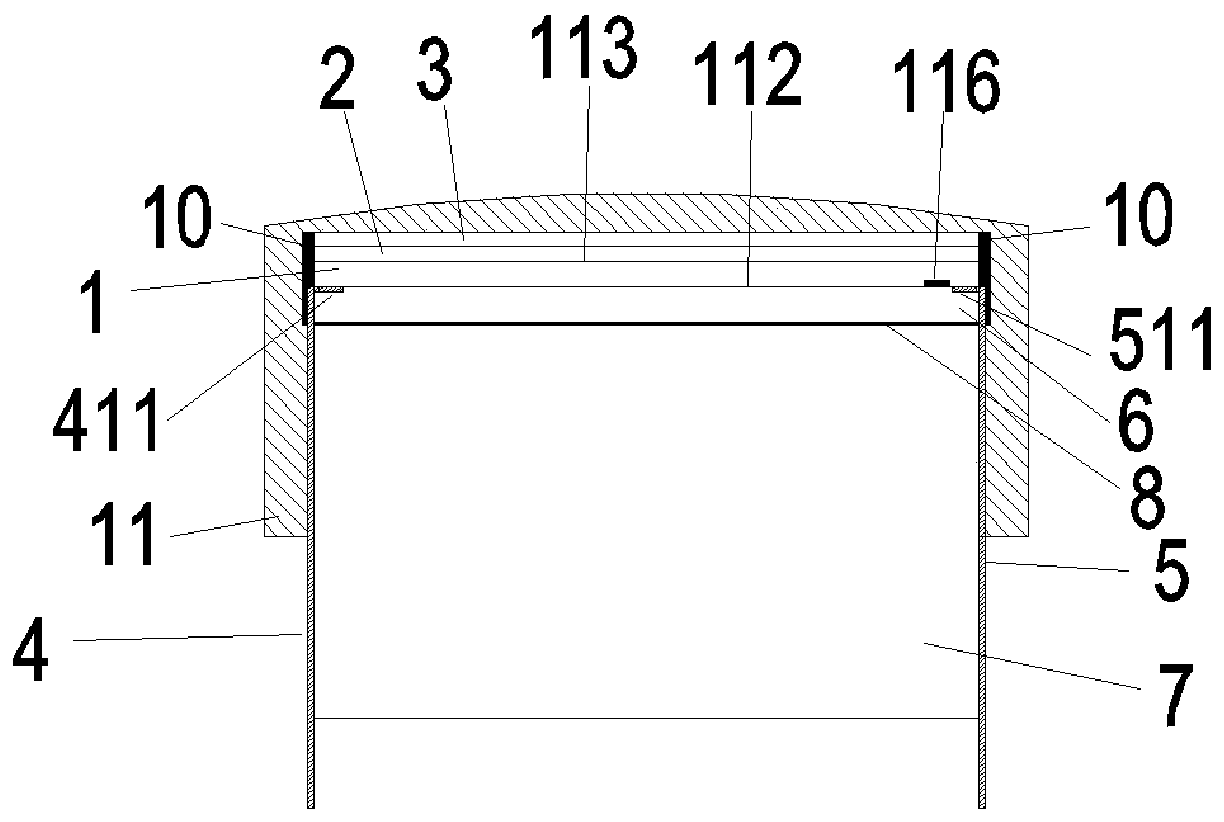

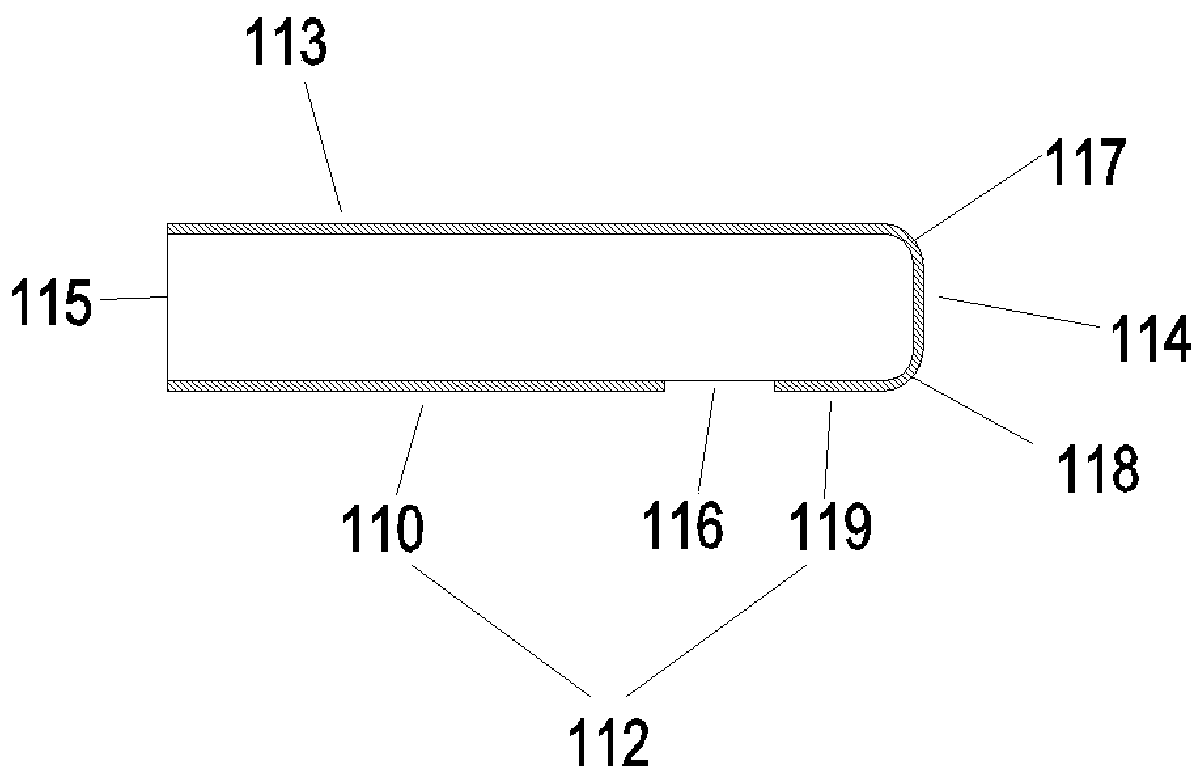

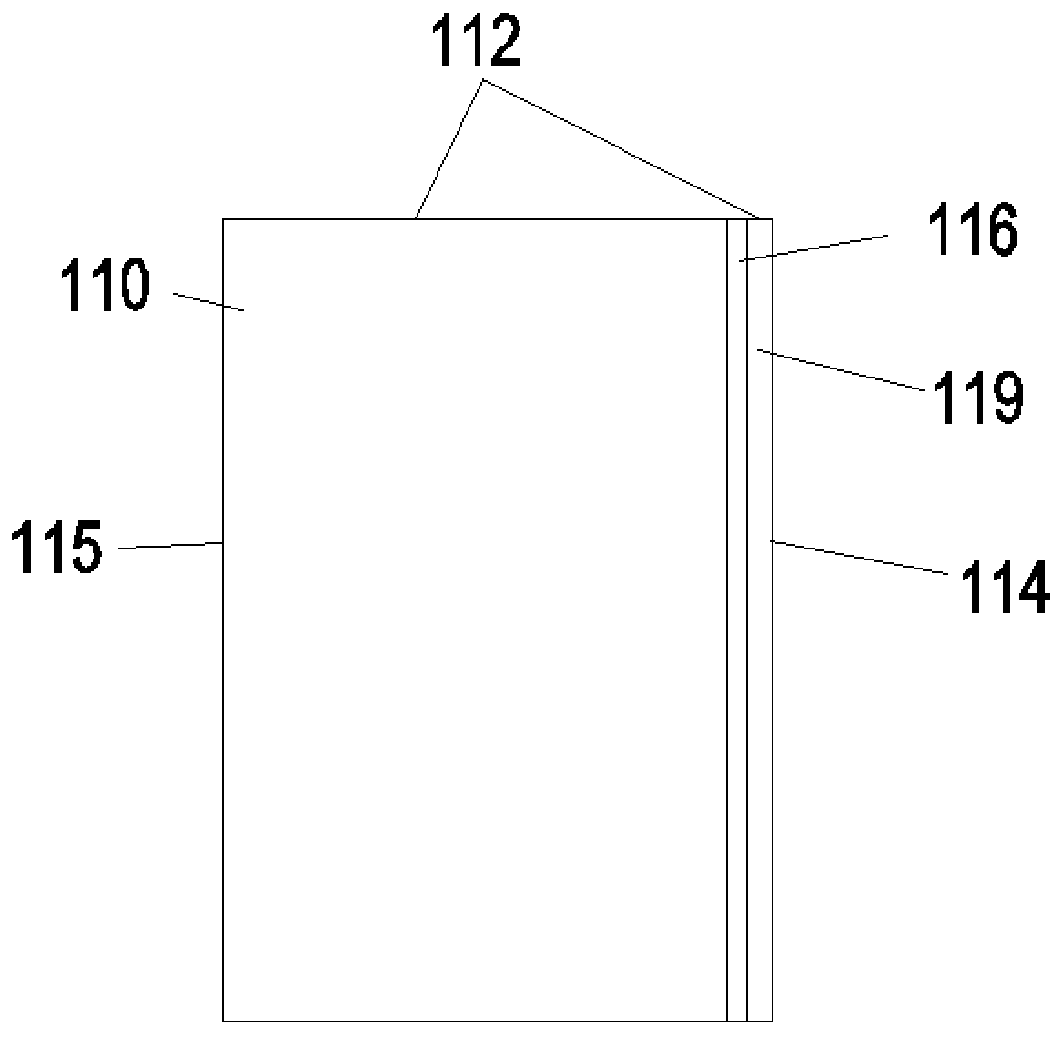

[0025] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0026] In the prior art, in the scheme of using air filling to support the structure of each array element of the piezoelectric layer, the tangent method is generally adopted, that is, the matching layer material, the piezoelectric material and the backing material are all cut, so that each array element Completely isolated. Then stick a layer of film material on the outer surface of the matching layer material to protect the array element and the slit, so as to prevent the lens glue or the glue bonding the lens and the matching layer from entering the gap, and ensure that the gap betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com