Comprehensive fire extinguishing system and fire extinguishing method for large floating roof tank fire

A technology of fire extinguishing system and floating roof tank, which is applied in the field of comprehensive fire extinguishing system for large floating roof tank fires, which can solve the difficulty in meeting the actual needs of fire extinguishing protection, lose the technical advantages of fixed system directional application and rapid fire extinguishing, and the ability to resist recombustion Weakness and other problems, to achieve good promotion and application value and potential, solve technical problems in fire prevention and control, and strong anti-resurgence ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

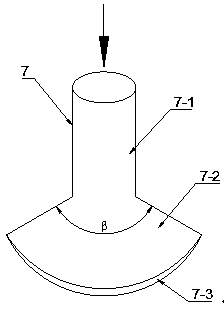

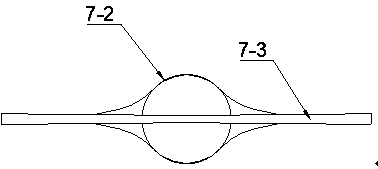

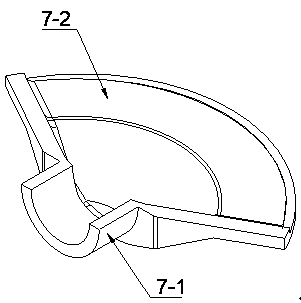

[0039] like Figure 8 As shown, ten duckbill foam release heads and two combined foam release devices 8 are evenly arranged on the roof of the floating roof tank. Compressed gas foam generation system 1, fixed compressed gas foam generation system 1 generates high-stability compressed gas foam according to the preset flow rate, and transports it to each duckbill foam dispensing head 7 and combination through fire main pipe 4 and fire branch pipe 6 Type foam dispensing device 8, because the flow rate of compressed gas foam is small, the working pressure of distributing device is low, can't reach the cracking pressure of burst disc 15-3 in the gun head 15 of combined type foam dispensing device 8, so compressed gas foam all passes through each The duckbill foam dispensing head 7 and the duckbill foam dispensing head 7 of the combined foam dispensing device spray and extinguish the fire;

[0040] When a floating roof oil spill fire occurs in the floating roof tank: the fire alar...

Embodiment 2

[0042] like Figure 9 As shown, six duckbill foam release heads 7 and six combined foam release devices 8 are evenly arranged on the roof of the floating roof tank 9. When a full liquid level fire occurs in the floating roof tank: the fire alarm controller sends an alarm signal and Start the fixed compressed gas foam generating system 1, and the fixed compressed gas foam generating system 1 generates compressed gas foam with high stability according to the preset maximum flow rate, and at the same time close the main distribution valve 14, and the fixed compressed gas foam generating system 1 is specially used for Six duckbill foam dispensing heads 7 provide foam for six combined foam dispensing devices 8 through mobile compressed gas foam generating equipment 12 through fire hose 13, and the increase of compressed gas foam flow makes the combined foam dispensing device 8 The working pressure is significantly increased, thereby opening the rupture disk 15-3 in the nozzle 15 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com