A kind of bouncing flapping wing robot and its bouncing flapping wing method

A robot and rack technology, applied in the field of robotics, can solve problems such as deviation from expectations, large energy consumption, and large landing impact, and achieve the effects of reducing device weight, enhancing bounce stability, and increasing bounce height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

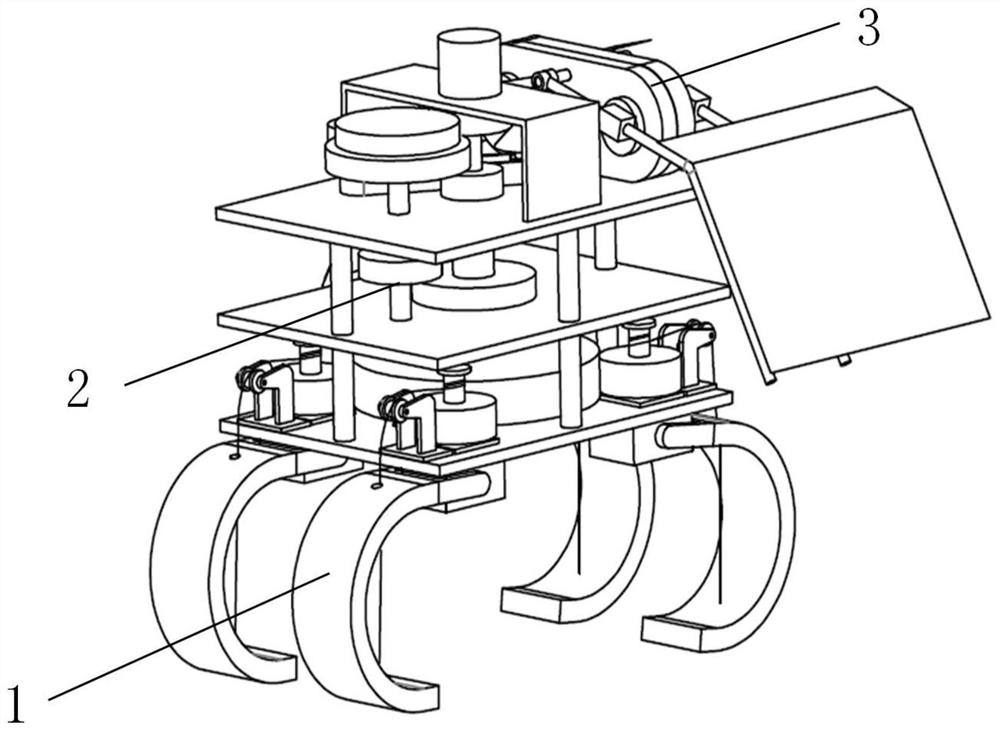

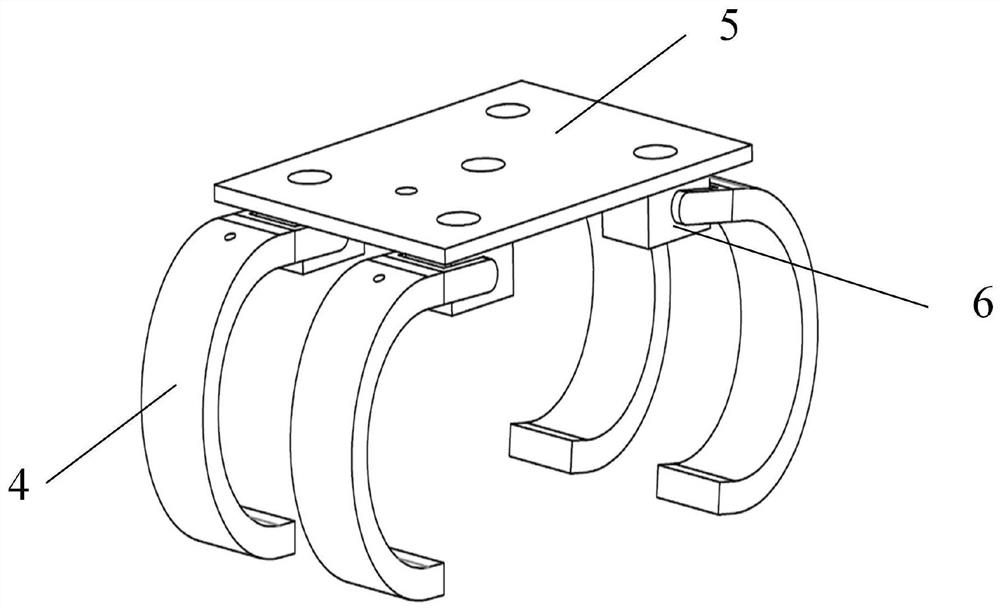

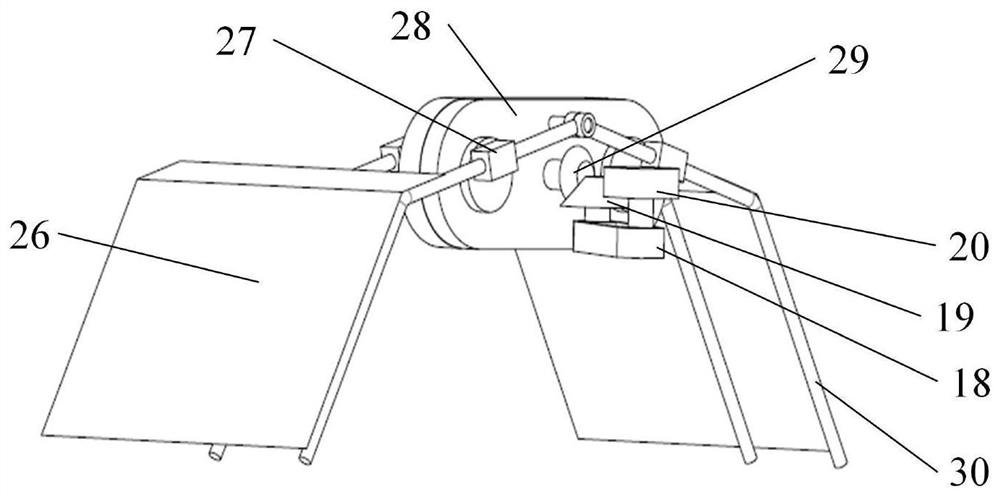

[0039] Such as figure 1 As shown, a bounce flapping wing robot includes a frame, a bounce mechanism 1, a multiplexing drive mechanism 2, a flapping wing mechanism 3, and a control sensor system. The frame includes a bounce base plate 5, a middle base plate 9 and a flapping wing top plate 31 arranged and fixed together in sequence, forming a three-layer gear placement position.

[0040] Such as figure 1 with 2 As shown, the bounce mechanism 1 is installed at the bottom of the entire device, and includes four steering gears 6 and four spring legs 4. The bounce bottom plate 5 is a plate of 250mm×150mm×10mm. Four steering gears 6 are fixed on the four corners of the bottom surface of the bounce base plate 5. The output shaft of the four servos 6. The elastic leg 4 is made of elastic material, specifically rubber. The leg 4 is C-shaped. The inner ends of the elastic legs 4 are provided with rope holes. The inner ends of the four spring legs 4 are fixed to the output shafts of the...

Embodiment 2

[0059] A bouncing flapping wing robot differs from Embodiment 1 in that the material of the switching ring is a permanent magnet, and one of its magnetic poles faces the switching electromagnet.

[0060] In the bouncing flapping method of the bouncing flapping wing robot, the direction of the magnetic pole is changed by switching the forward and reverse energization of the electromagnet, thereby realizing the switching of the switching axis between the upper limit position and the lower limit position. When the switching electromagnet generates repulsive force on the switching ring, the switching shaft is at the lower limit position; when the switching electromagnet generates attraction to the switching ring, the switching shaft is at the upper limit position; embodiment 2 is relative to embodiment 1, the position of the switching shaft is adjusted It is more stable and reliable without relying on gravity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com