Secondary-granulation powder feeding device

A feeding device and secondary granulation technology, applied in the field of secondary granulated powder feeding device and powder supply device, can solve the problem of inefficient and continuous accurate feeding, powder crushing out of roundness, and powder damage. Body shape and other problems, to achieve the effect of solving broken and out-of-round, reducing collision and extrusion, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments are provided below and the present invention is further described in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

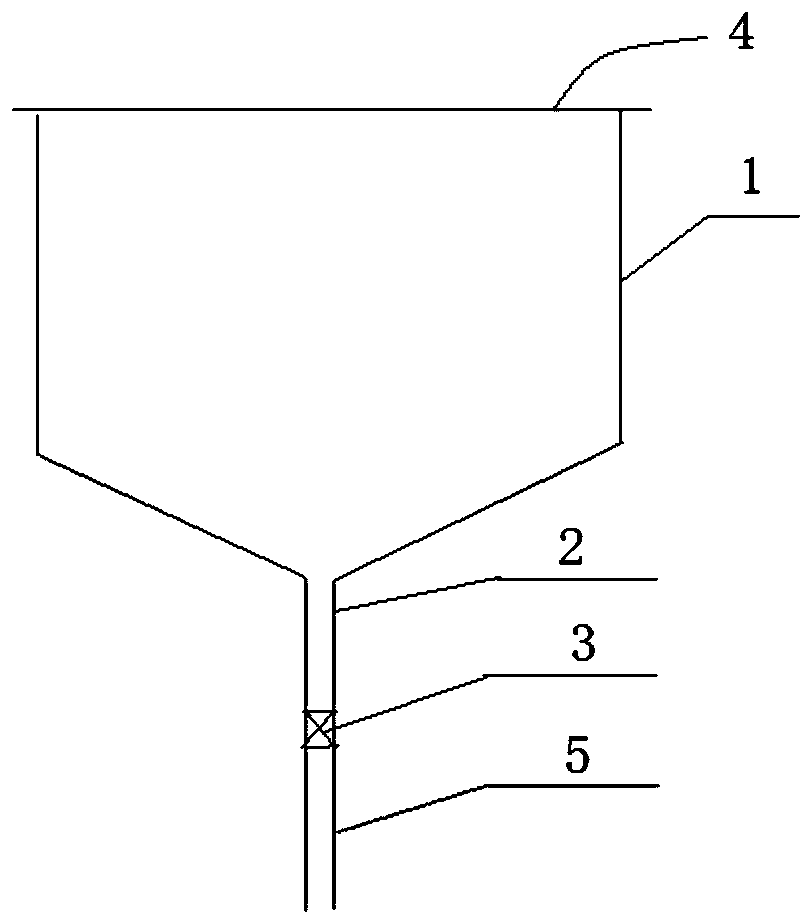

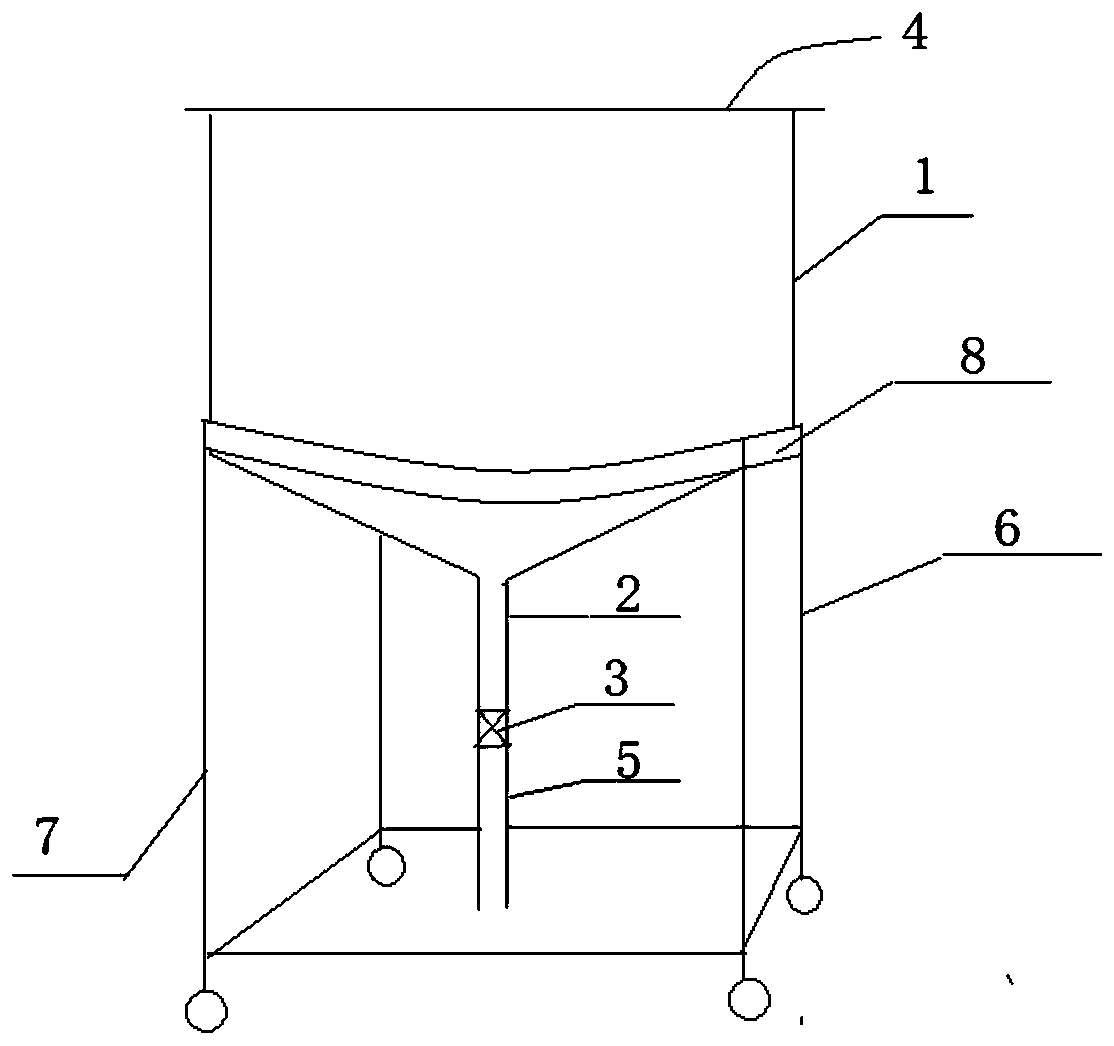

[0020] Such as figure 1 with figure 2 As shown, the secondary granulation powder feeding device of the present invention includes: a silo 1, a discharge port 2 at the bottom of the silo, a control valve 3 arranged at the discharge port, and a dust cover 4.

[0021] The upper part of the feed bin 1 is a cylindrical structure, usually the diameter of the cylinder is slightly greater than the height of the cylinder, and the bottom of the feed bin 1 is a funnel-shaped structure, which is integrated with the upper cylindrical structure. The inside of the silo 1 is hollow and is a place for storing materials. The silo 1 needs to be designed according to the requirements of the process, such as output, working hours, load-bearing, and working space.

[0022] The bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com