Mutual-inserted rail-side signal equipment floor hardeners and mounting method thereof

A technology of ground hardening and signal equipment, which is applied in the fields of soil protection, construction, and infrastructure engineering. It can solve the problems of different weights on both sides of the roadbed, many processes on the cement hardened surface, and no cement construction is allowed, so as to achieve fast construction. The effect of fast construction progress and simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

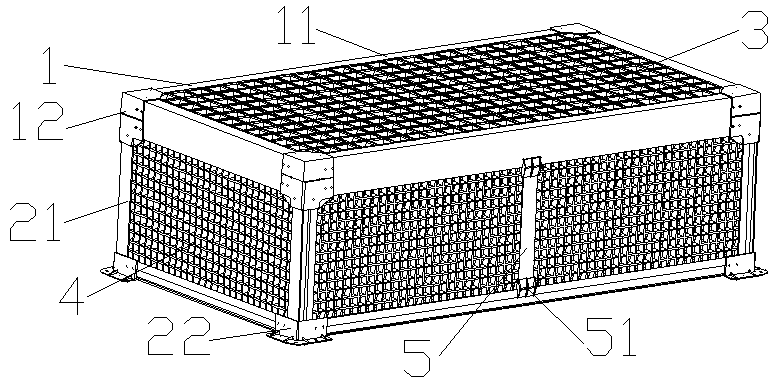

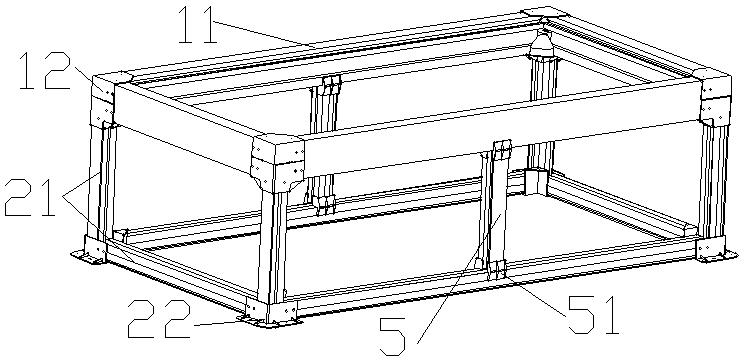

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the ground hardening of a kind of interconnected wayside signal equipment provided by the present invention includes an upper plane frame 1, a surrounding platform, a hardened surface panel, and a grid plate 4; the upper plane frame 1 is rectangular; the The hardened surface panel is fixedly installed on the upper plane frame 1 by self-tapping screws or rivets; the surrounding platform is a rectangular parallelepiped frame and is fixedly installed under the upper plane frame 1; the grid plate 4 is fixed on on the four sides of the enclosure.

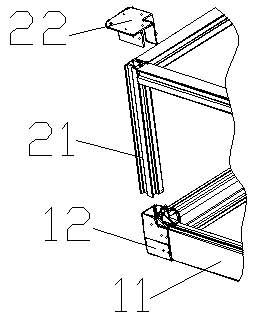

[0032] Specifically, the upper plane frame 1 is composed of several profiles 11, and two adjacent profiles 11 are connected by a three-way wrap angle 12; the three-way wrap angle 12 is right-angled, and the three-way wrap angle 12, two through holes on the same plane are respectively connected with two adjacent profiles 12.

[0033] Spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com