Axial flow fan with reinforcing rib structure

An axial flow fan and reinforcing rib technology, which is applied to the components of the pumping device for elastic fluid, non-variable displacement pump, machine/engine, etc. Achieve the effect of reducing risk, reducing blade deformation, and increasing strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

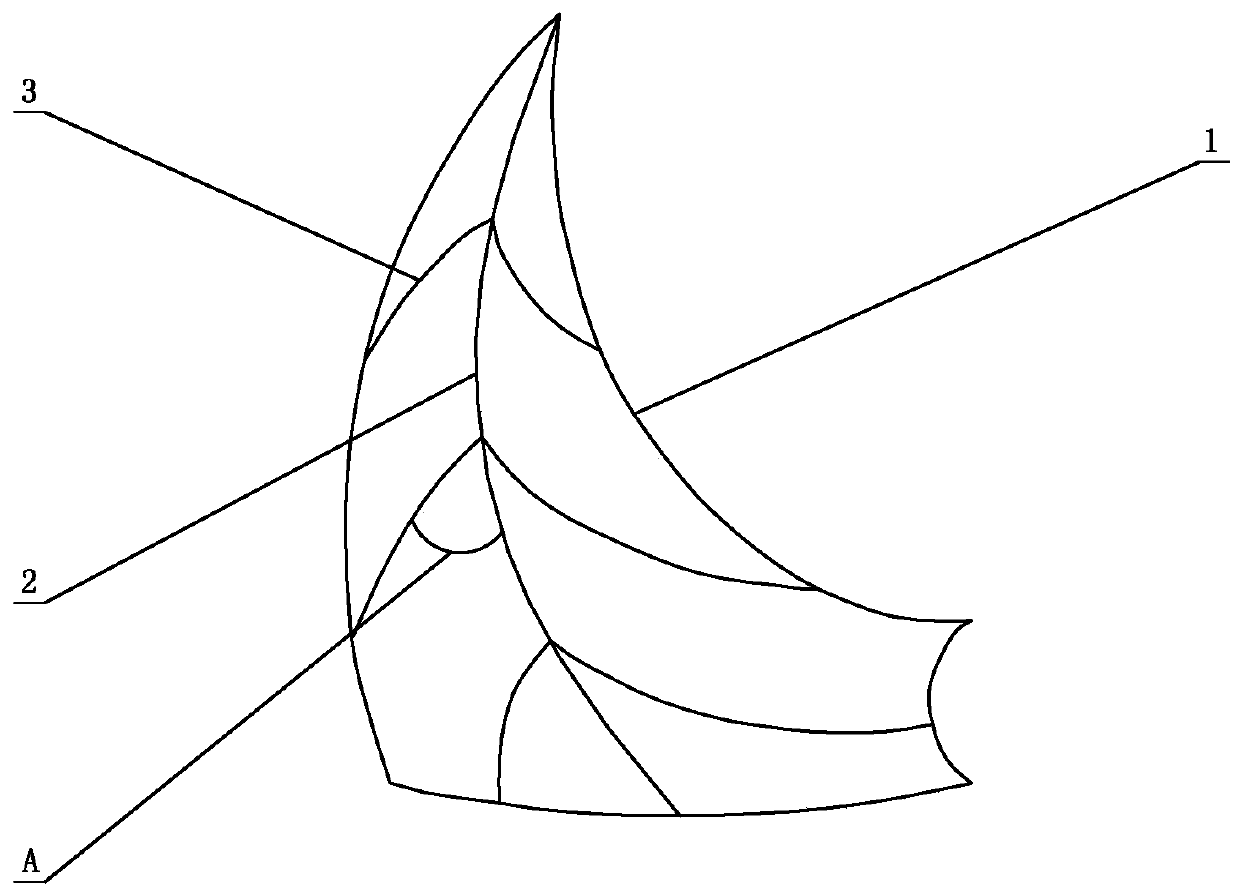

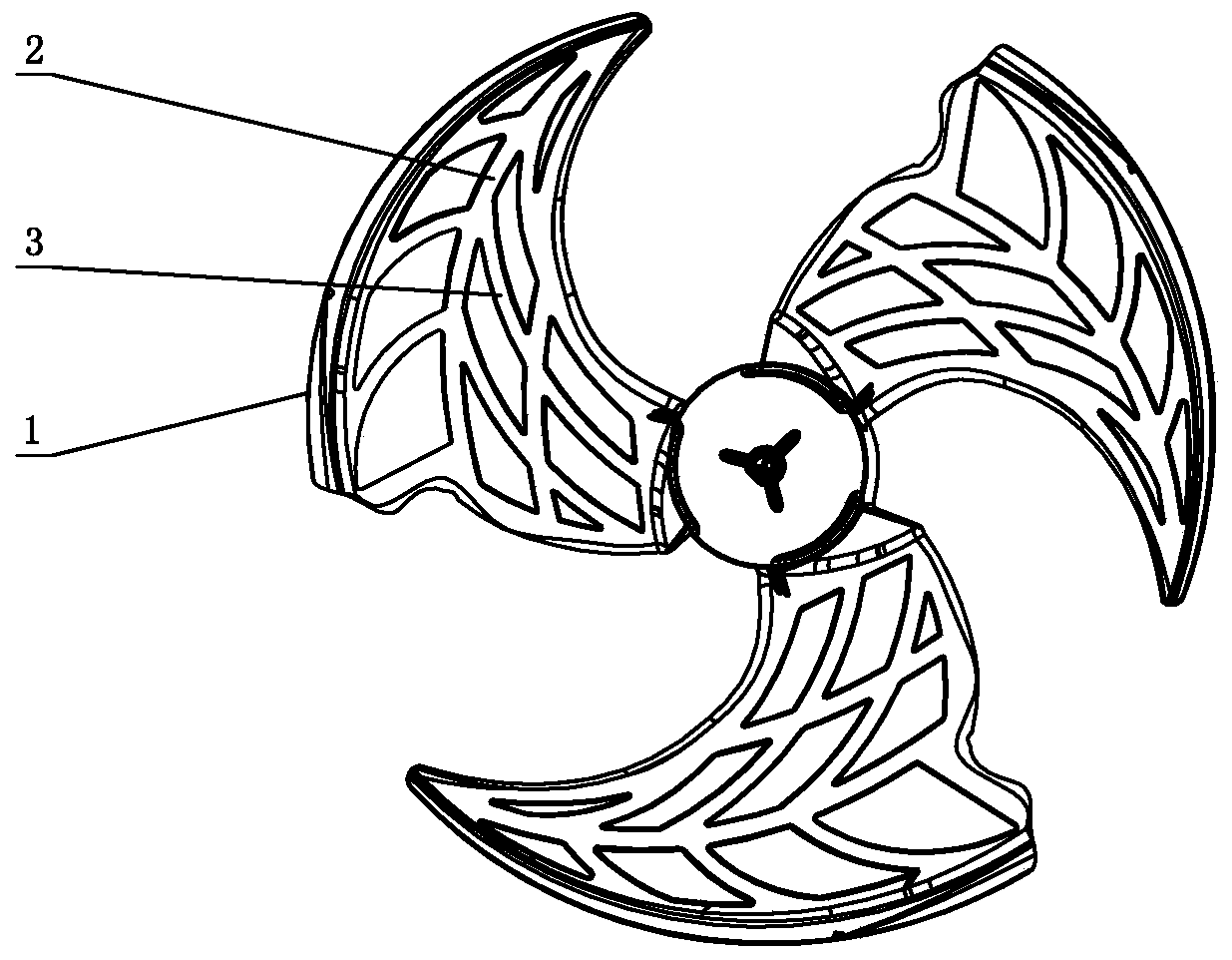

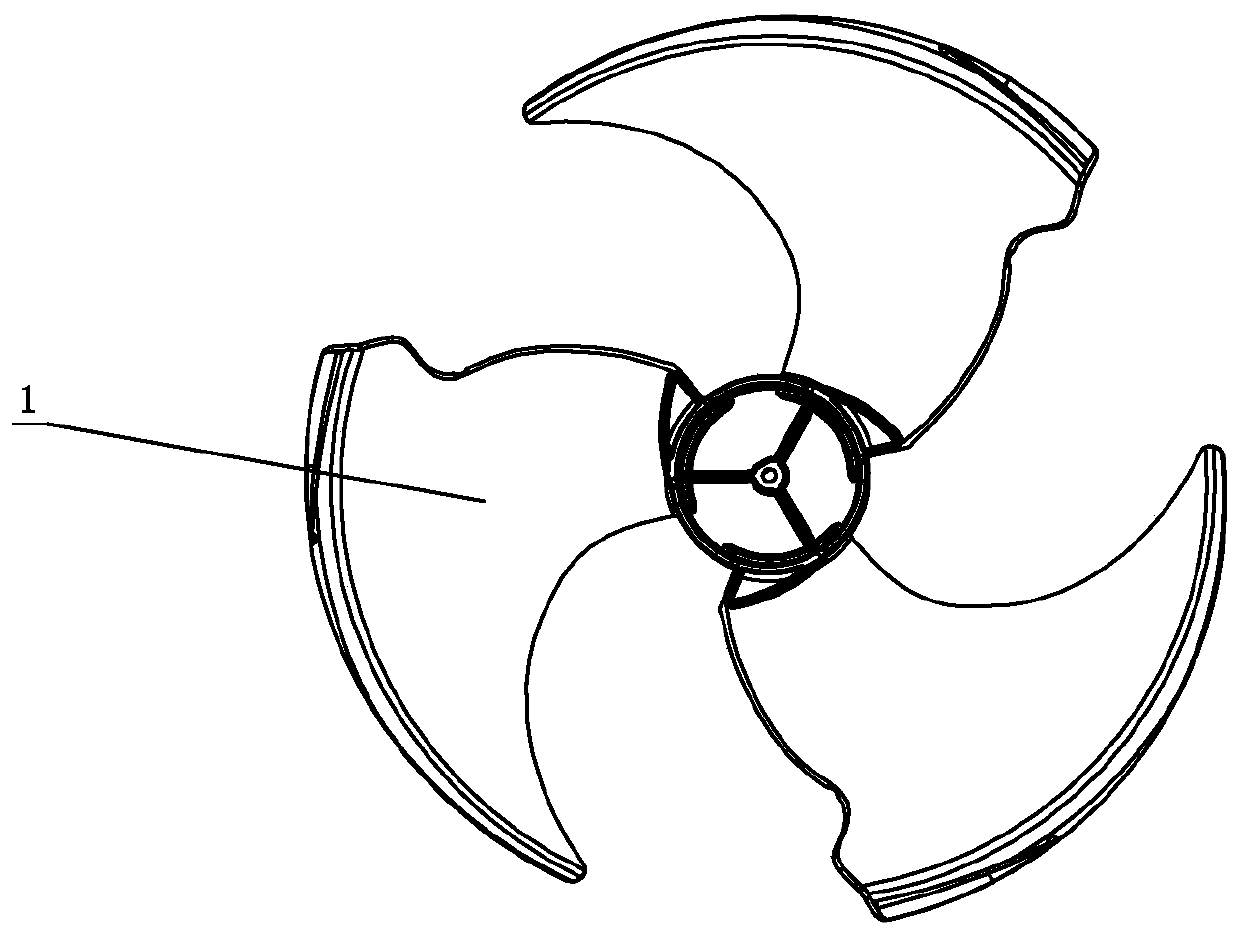

[0026] see Figure 1-Figure 3 , an axial flow fan with a rib structure, comprising a blade 1, the blade 1 is respectively provided with more than one first rib 2 and second rib 3 in the longitudinal direction and the transverse direction, so that several ribs are formed on the blade 1 Bosses, and an airflow guiding area is formed between two adjacent bosses; wherein, more than one second rib 3 extends from one or both sides of the first rib 2, and the first rib 2 and the second rib 3 Spline curves in arc shape or polyline combination respectively. Polylines include arcs and lines.

[0027] The first rib 2 and the second rib 3 increase the strength and rigidity of the blade 1 , reduce the deformation of the blade during the operation of the axial flow fan, and reduce the risk of the blade 1 being broken.

[0028] The first and second ribs 2, 3 and the small boss structure on the surface of the blade 1 will generate turbulence when the blade 1 rotates, thereby destroying the b...

no. 2 example

[0033] see Figure 4 An axial flow fan with rib structure is different from the first embodiment in that the second rib 3 on one side of the first rib 2 is provided with a third rib 4, and the third rib 4 is longitudinally arranged on the blade 1 on.

[0034] The cross-sections of the first, second and third ribs 2, 3, and 4 are rectangular, stepped, triangular, semicircular or polygonal, and the dimensions of the first, second, and third ribs 2, 3, and 4 are respectively = 1-3 times of the maximum thickness of the blade 1, the cross-sectional area of the second rib 3=50%-70% of the cross-sectional area of the first rib 2, the third rib 4=25%-50% of the first rib 2 Sectional area.

[0035] A third rib 4 is connected between two adjacent second ribs 3 on one side of the first rib 2 , so that two adjacent second ribs 3 and third ribs 4 form a closed loop.

[0036] The third reinforcing rib 4 is separated from the 1 / 2 of the second reinforcing rib 3 on the side of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com