A construction method of micro-differential networking outside the hole for vibration-reducing blasting of underground excavation tunnels

A construction method and tunnel technology, applied in blasting and other directions, can solve problems such as safety, construction period and benefit impact, difficulty in meeting construction requirements, poor single-stage blasting effect, etc., to achieve long blasting interval, simple construction, and safe blasting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

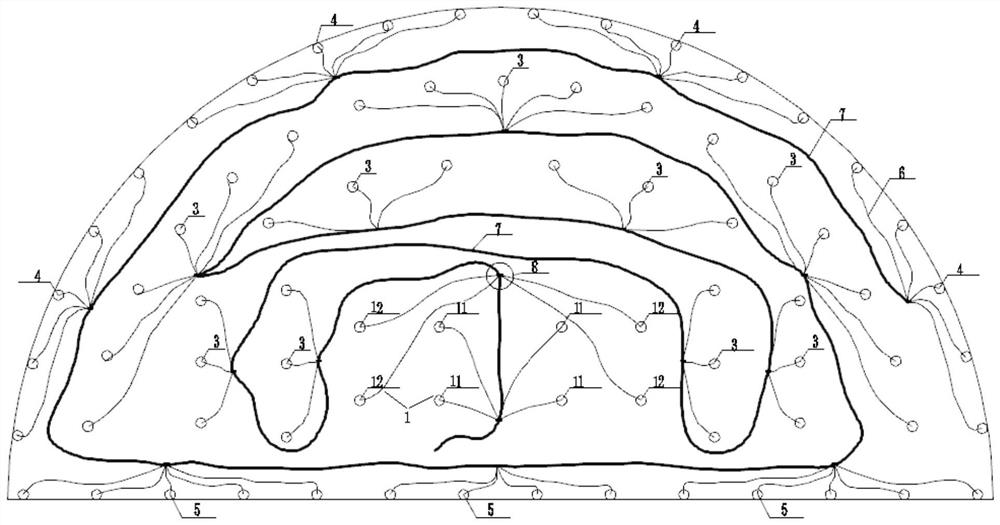

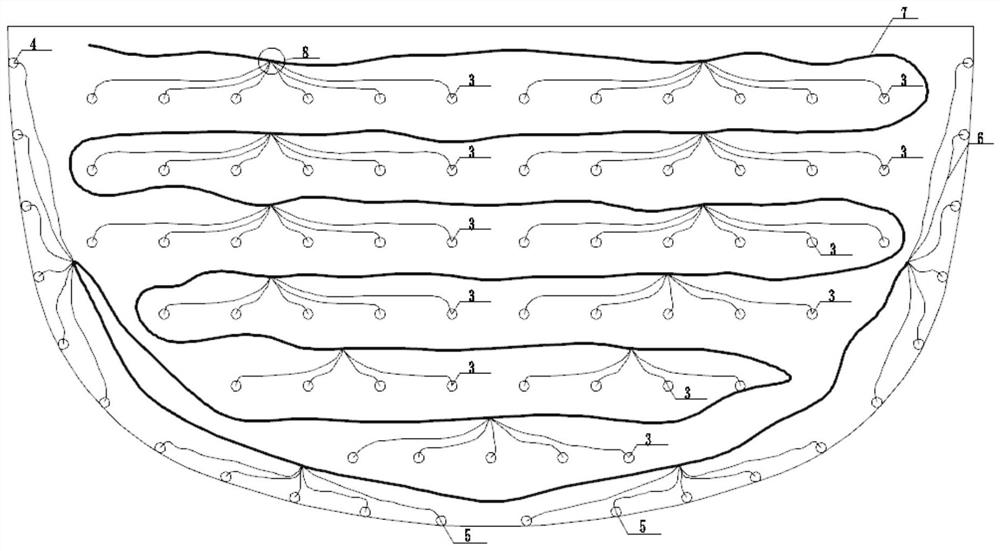

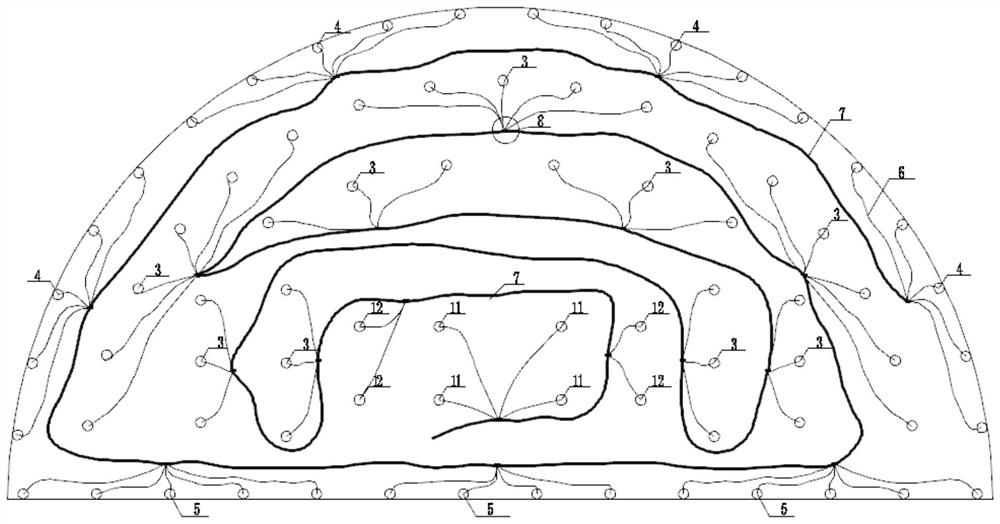

[0061] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0062] like Figure 1 to Figure 7 As shown, the method includes:

[0063] Step 1. Obtain the blasthole parameters, which include the type of blasthole, the position of the blasthole, the number of blastholes, the depth of the blasthole and the single-hole charge;

[0064] Step 1.1, determine the medium coefficient K and attenuation coefficient α of the excavation section according to the lithology, here, the value of K is 200, and the value of α is 1.65;

[0065] Step 1.2, according to the protection object, determine the distance R from the charging center to the protected building and the particle vibration velocity V, where R is 50m and V is 5cm / s;

[0066] Step 1.3, according to the following Saxophone formula (1), calculate the single-stage maximum detonating charge Qmax:

[0067] V=K(Q 1 / 3 / R) α ……(1),

[0068] From the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com