Soft rock shearing box for simulating blasting effect

A technology of shear box and soft rock, applied in the field of shear box, which can solve the problems of inability to simulate and transform the influence of blasting construction parameters, inability to simulate realistically, large difference between blasting vibration frequency and peak vibration velocity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

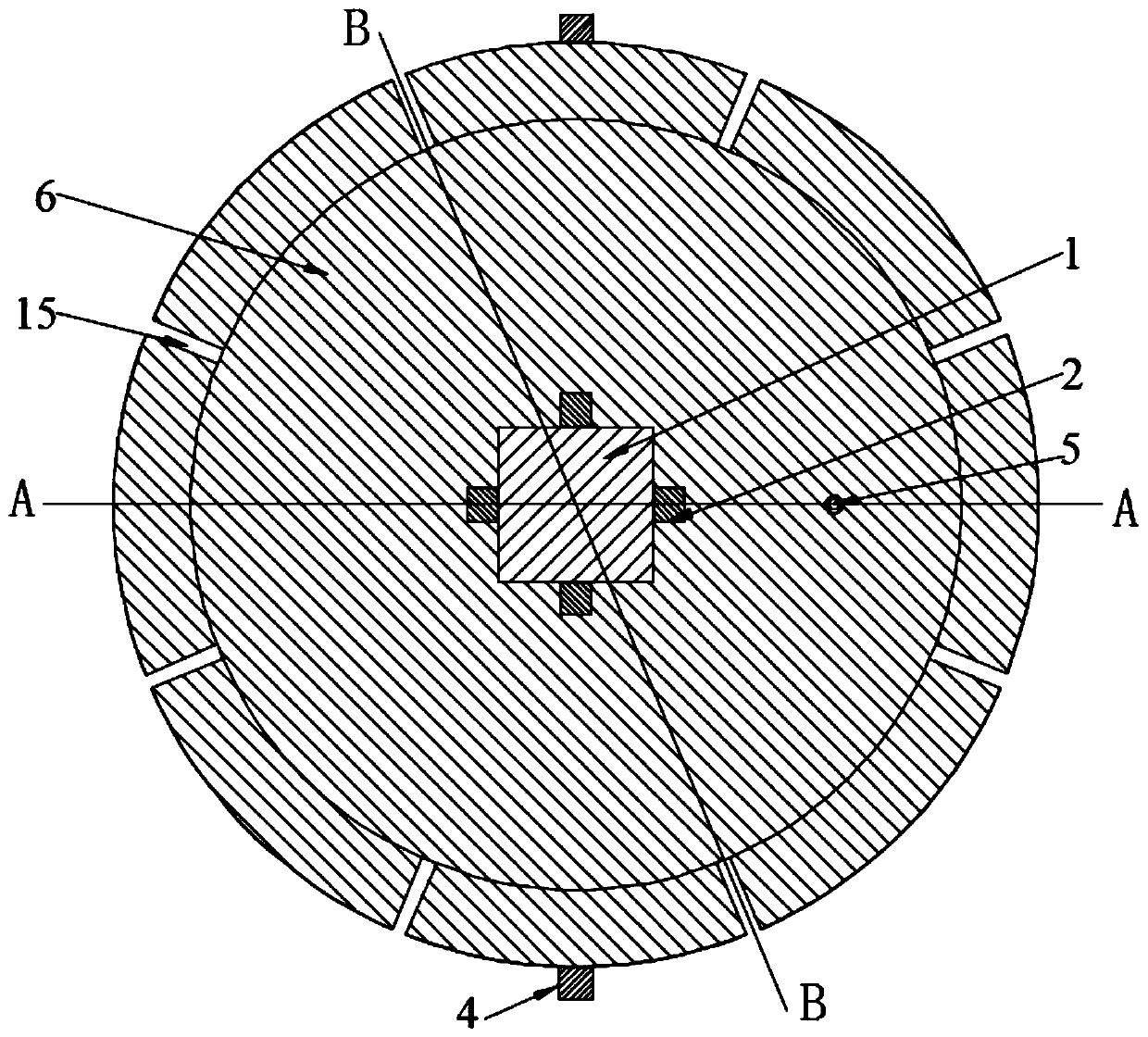

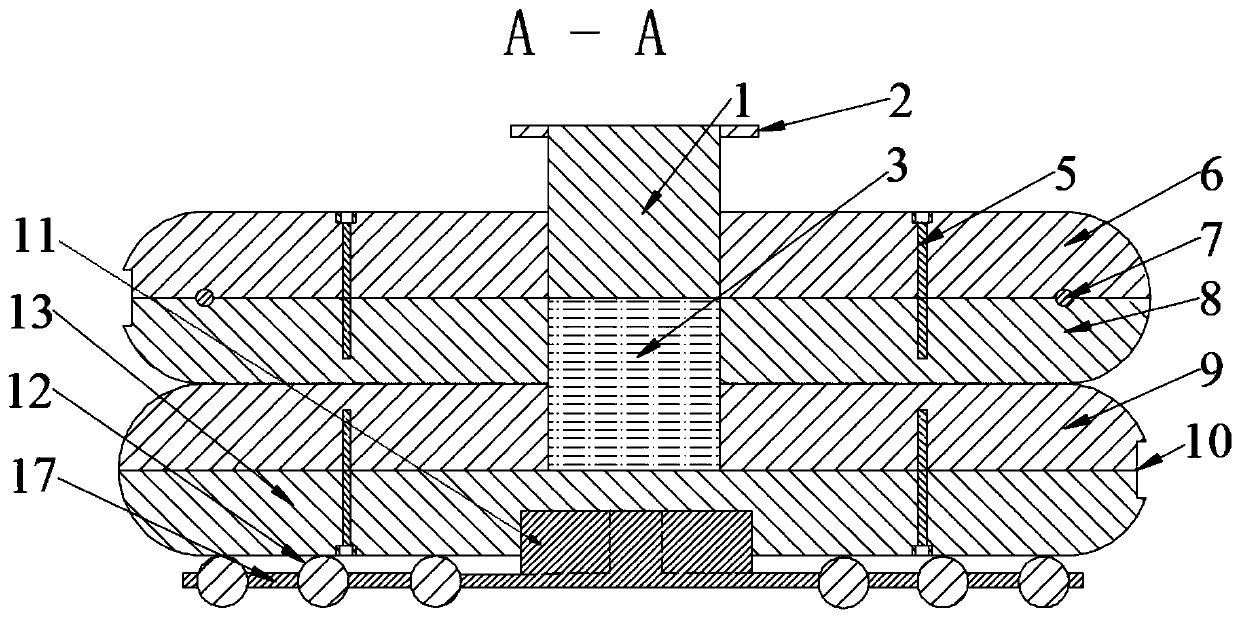

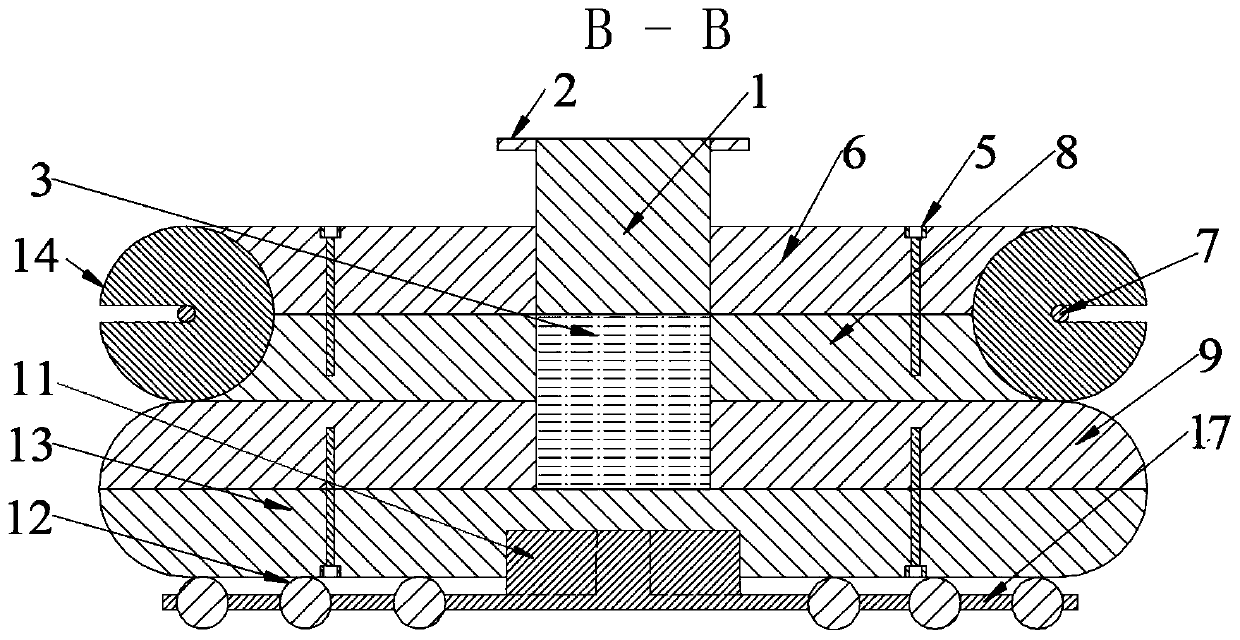

[0034] Embodiment 1: The present invention provides a soft rock shear box for simulating blasting, the structure of the shear box is as follows Figure 1-7 shown. It includes at least an upper shear box, a lower shear box, a normal loading pad 1 and a sliding roller 17; the center of the upper shear box and the lower shear box is provided with a cavity for placing the rock sample 3, and the upper part of the rock sample is provided with Normal load pads.

[0035] Such as figure 1 A square plate 2 for installing a normal displacement sensor is welded to the middle of the four sides of the top of the normal loading pad 1 .

[0036] Such as figure 1 , 2 , 3, the upper shear box is formed by connecting the upper top plate 6 and the upper shear body 8 with long screws 5, and the center of the junction between the upper top plate and the upper shear body is provided with a cavity around the cavity where the rock sample 3 is placed. An annular groove, the annular groove is used ...

Embodiment 2

[0052] Embodiment 2: The present invention provides a soft rock shear box for simulating blasting. The structure of the shear box is basically the same as in Example 1, except that there are 10 flat columns evenly distributed around the upper shear box. Shape groove 15, when simulating the effect of blasting on the impact of rock sample shear rheological effect, all or part of the charge can be tested in 10 charge test tubes.

Embodiment 3

[0053] Embodiment 3: The present invention provides a soft rock shear box for simulating blasting. The structure of the shear box is basically the same as in Example 1, except that there are 6 flat columns evenly distributed around the upper shear box. shaped groove 15, when simulating the impact of blasting on the shear rheological effect of rock samples, the test can be carried out in 6 charge test tubes with or without charge in stages.

[0054] The shear box of the present invention has a scientific and reasonable structure, high efficiency and good accuracy when using the shear box for testing, and is suitable for indoor shear rheological tests under simulated blasting vibrations, and can more realistically simulate blasting under different parameters The effect of vibration on the shear rheological effect of rock samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com