Wood fire spreading process testing device for irradiation environment

A technology of irradiation environment and process testing, applied in the direction of chemical analysis using combustion, etc., can solve the problems of small fixed parts, no consideration of the impact of ash falling, and no consideration of environmental radiation effects, to achieve flexible forms and prevent data errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

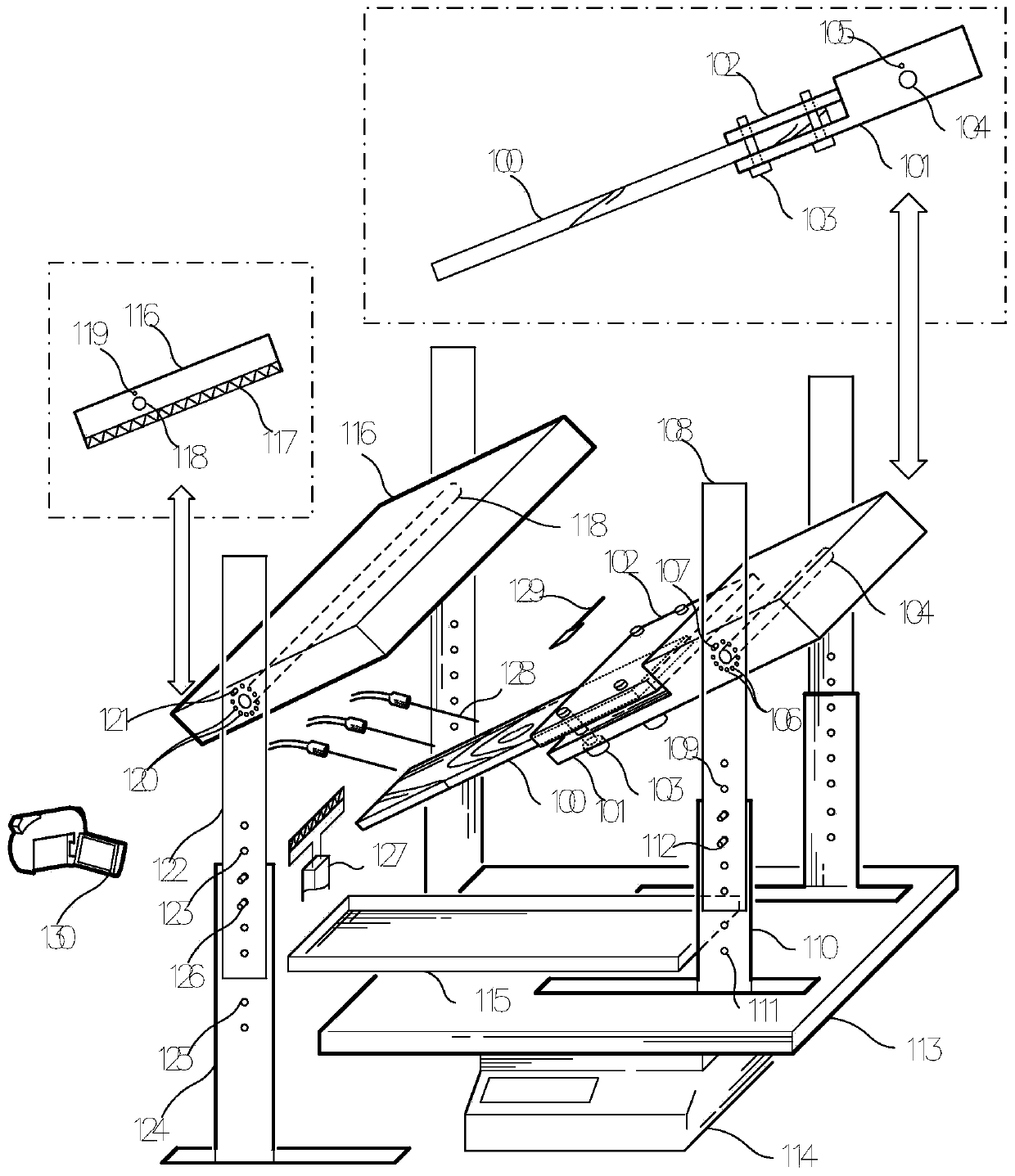

[0026] like figure 1 As shown, the present embodiment provides a test device for the process of wood fire spread in an irradiation environment, including a heating mechanism, an ignition mechanism, a radiation mechanism, a supporting mechanism, a measuring mechanism and a video shooting mechanism; the supporting mechanism is arranged on the measuring In terms of mechanism, the support mechanism is used to clamp the wood and adjust the angle of the wood, the ignition mechanism is used to ignite the wood, the heating mechanism is arranged between the wood and the radiation mechanism, and the video shooting Agency is used to photograph the wood burning process.

[0027] In this specific example, if figure 1 As shown, the ignition mechanism adopts a heating wire igniter 127, specifically, a bracket is used to clamp a heating wire, and the heating wire contacts the bottom of the wood by moving the bracket, and the wood is linearly ignited by the heat of the heating wire. Then tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com