Batching optimization method and system based on nonlinear opportunity constraint

An optimization method and non-linear technology, applied in gene models, genetic rules, instruments, etc., can solve the problems of increased smelting costs of zinc concentrate raw materials, large fluctuations in the quality of mixed zinc concentrates, and inconformity with the production process. Low, small error, stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

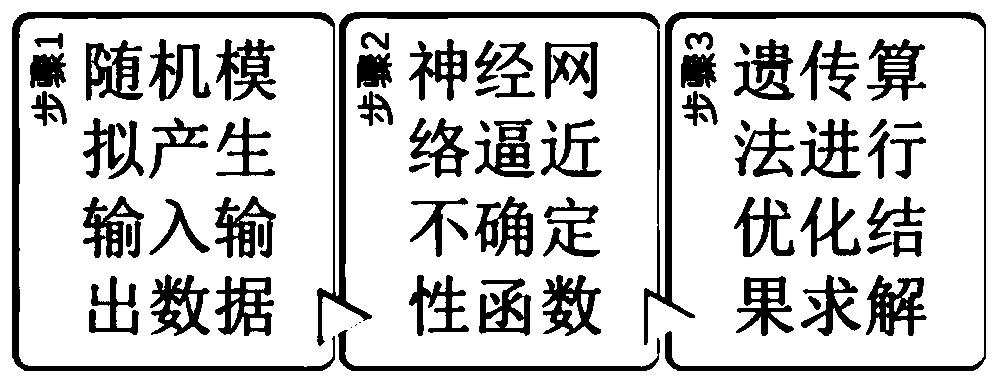

[0062] Such as figure 1 As shown, a batching optimization method based on nonlinear chance constraints, including the following steps:

[0063] Obtain the minimum value of the original zinc content of the mixed zinc concentrate in the historical data, the lower and upper limits of the quality of the mixed zinc concentrate, the upper and lower limits of the usage of various zinc concentrates, the zinc concentrate The type and its corresponding price, as well as the minimum or maximum content of each ore impurity element in each ore bin, the unit cost of zinc in the mixed zinc concentrate is the lowest, the usage of various zinc concentrates is used as the decision variable, and each The zinc element content and impurity element content in the zinc concentrate are random variables, and a nonlinear chance constrained programming model is constructed;

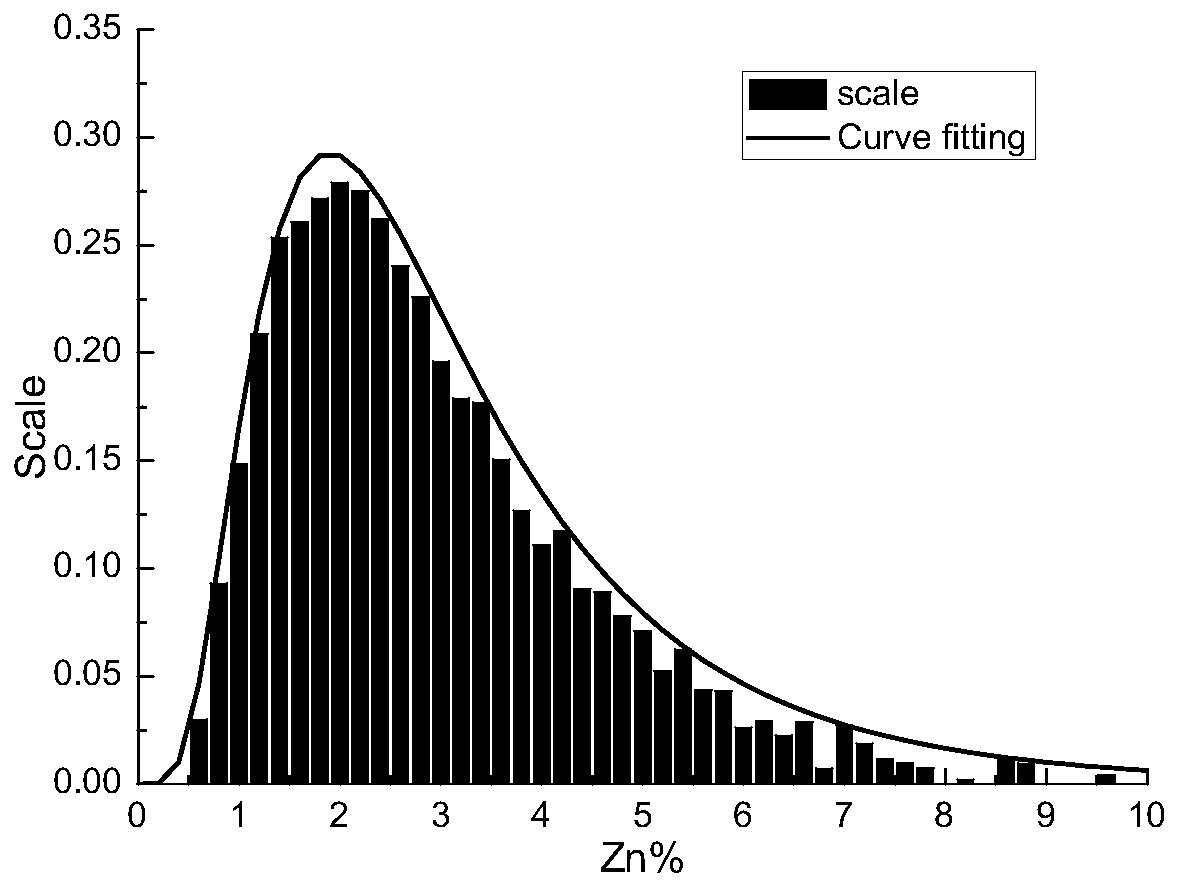

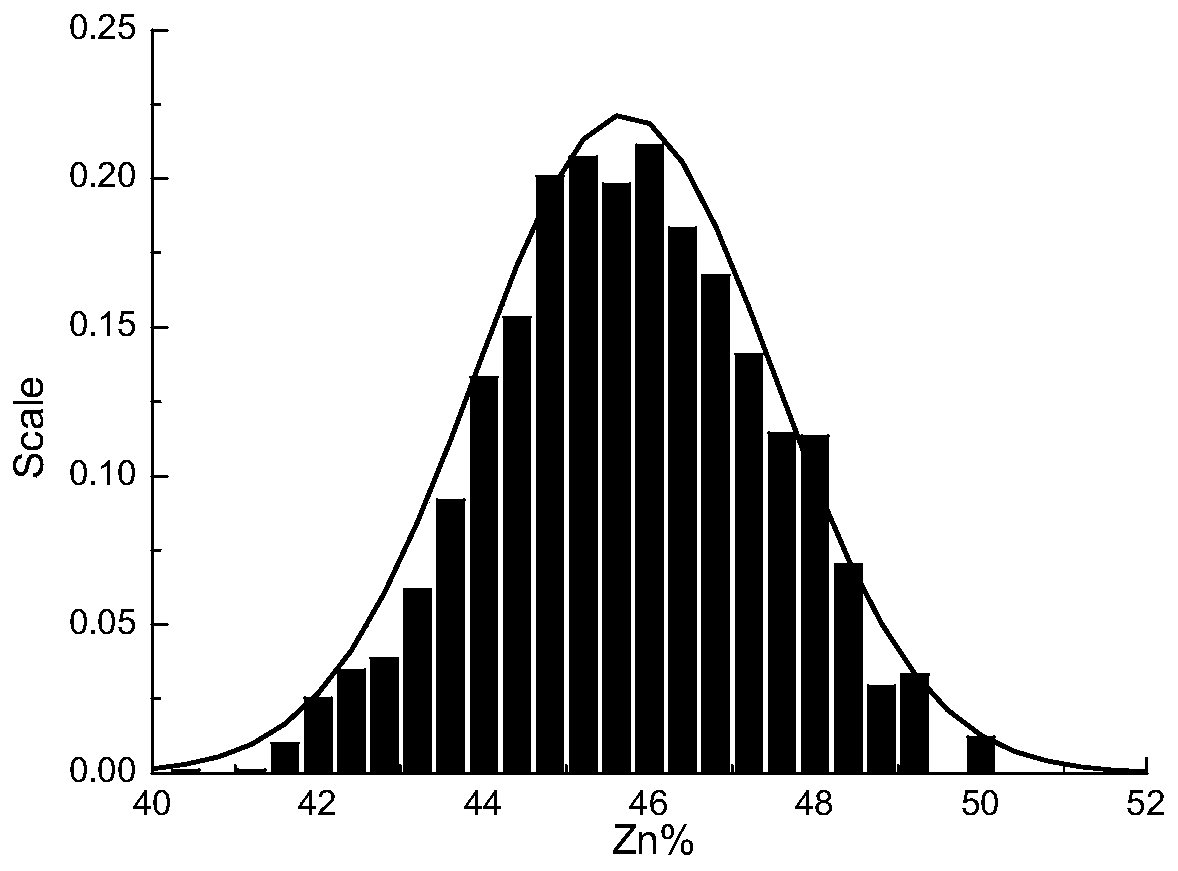

[0064] Obtain the mean values and variances of various zinc element contents and impurity element contents corresponding to va...

Embodiment 2

[0068] Embodiment 2 is an extended embodiment of Embodiment 1 of the present invention. It differs from Embodiment 1 in how to obtain the mean values and variances of various zinc element contents and impurity element contents corresponding to various zinc concentrates when they are put into storage. , How to construct a nonlinear chance constrained programming batching optimization model and solve the optimal solution of the nonlinear chance constrained programming model through the corresponding mean and variance of various zinc element contents and impurity element contents when various zinc concentrates are put into storage refined.

[0069] in,

[0070] Obtain the mean and variance of various zinc element contents and impurity element contents corresponding to various zinc concentrates when they enter the warehouse, specifically:

[0071] Zinc concentrates can generally be divided into four categories according to incoming materials, as shown in Table 1.

[0072] Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com