Flexible component mounting equipment

A technology for assembling equipment and flexible parts, which is applied in the field of automated machinery and equipment, and can solve the problems of low paste efficiency and poor precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

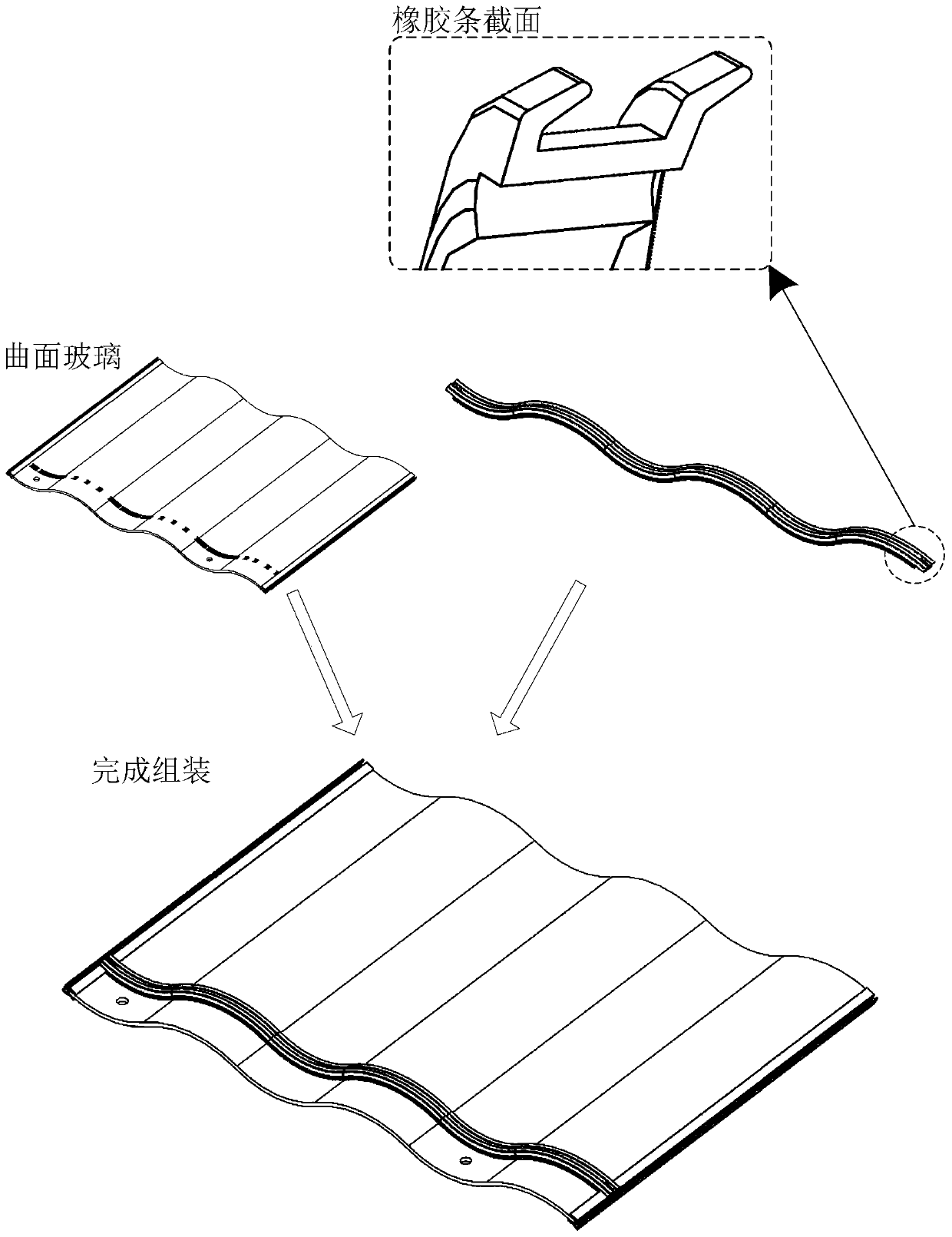

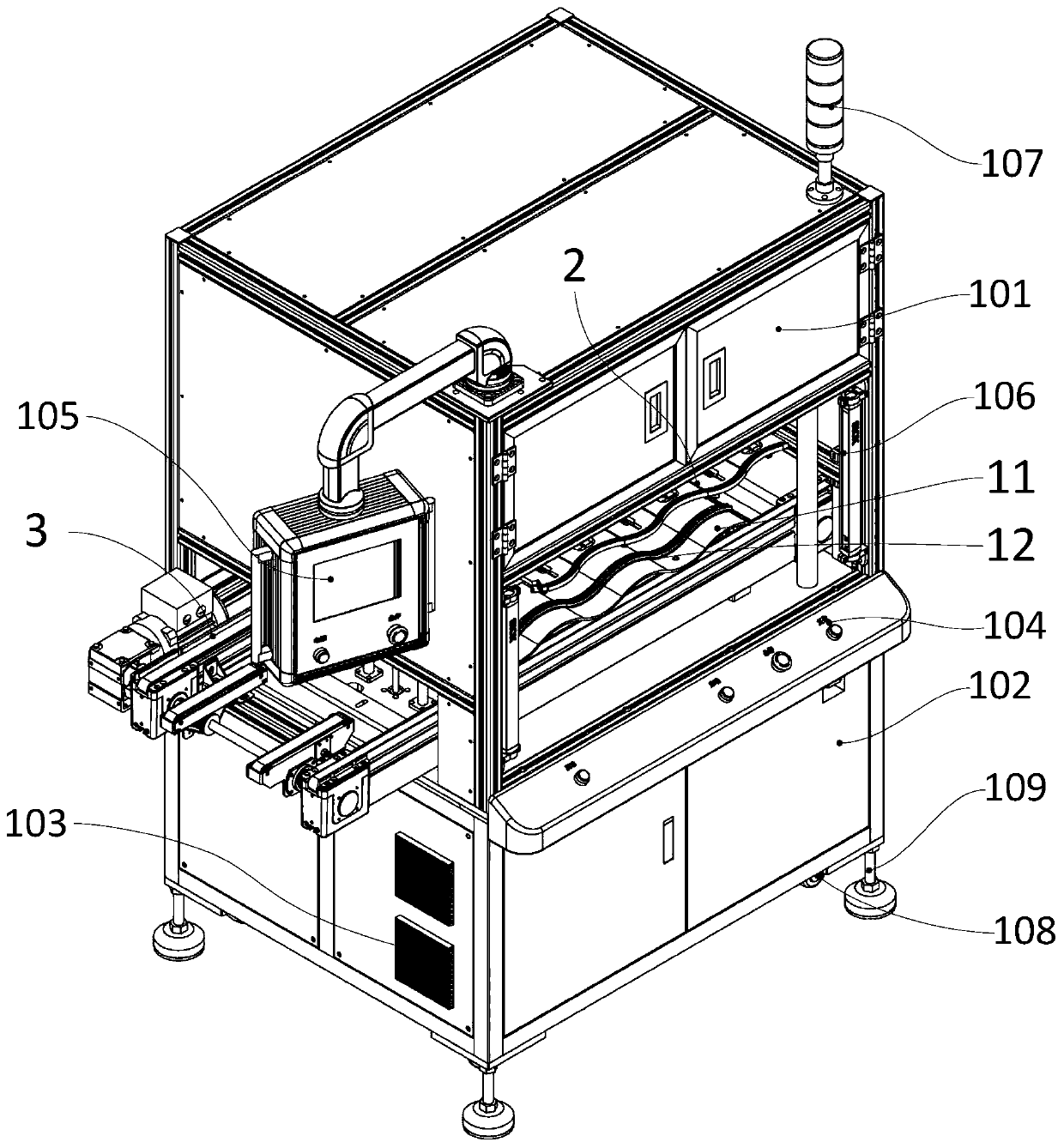

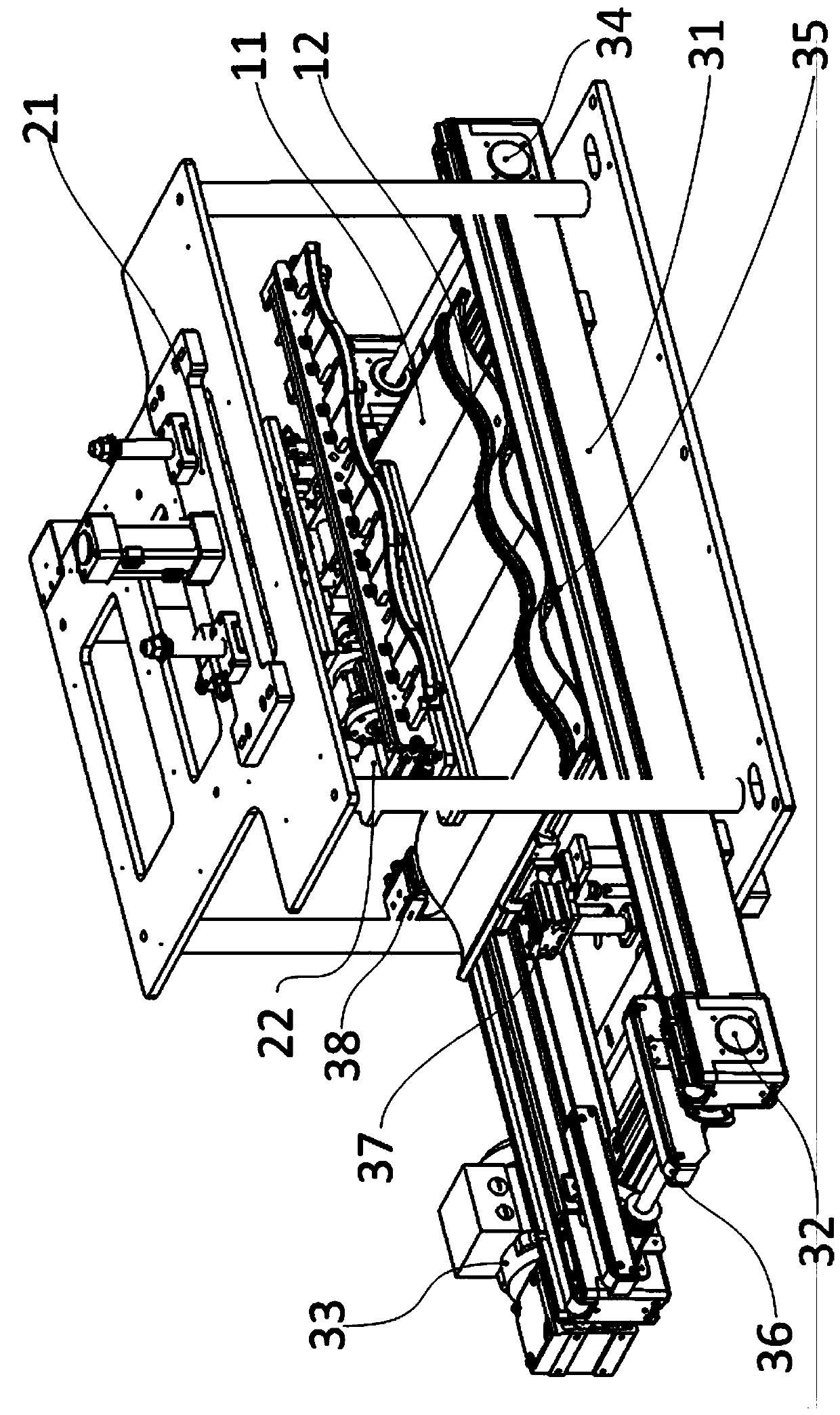

[0081] Such as figure 2 As shown, it is a schematic diagram of the overall appearance of the flexible component assembly equipment of the present invention, which is an independent automatic assembly equipment, including an external chassis, a frame, a control system, and an internal mechanical actuator; 11 in the figure is a flexible rubber strip to be pasted Curved glass, 12 is a flexible rubber strip; above the curved glass 11 is provided with a pasting actuator 2, and the curved glass 11 is placed on the conveyor 3; the pasting actuator 2 and conveyor 3 are installed on the equipment On the rack, the equipment rack is also equipped with:

[0082] (1) The upper frame 101 located above the equipment frame is used to set up and fix the pasting actuator 2;

[0083] (2) The lower frame 102 positioned below the equipment frame is used to set up and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com