Biogas fermenting pit having insulating structure

A biogas fermentation and fermentation tank technology, which is applied to specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, gas production bioreactor, etc. Winter heat preservation needs and other issues, to achieve the effect of simple structure, guaranteed output, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

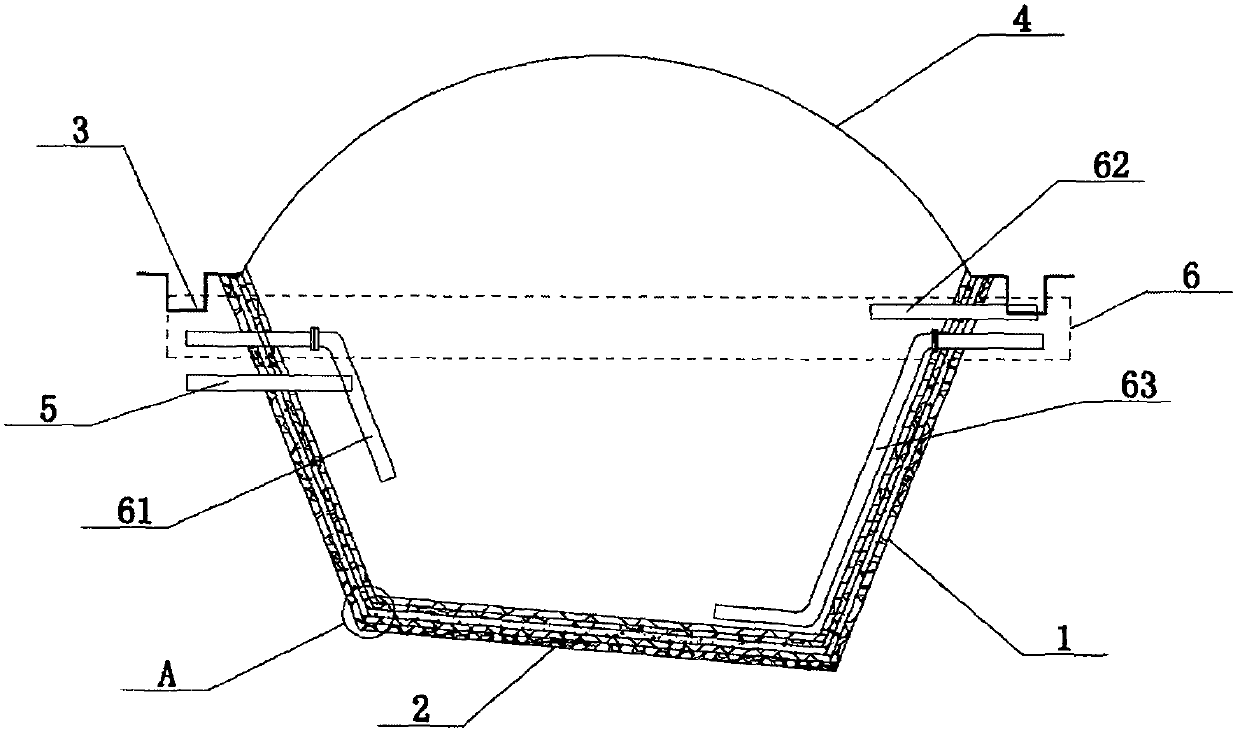

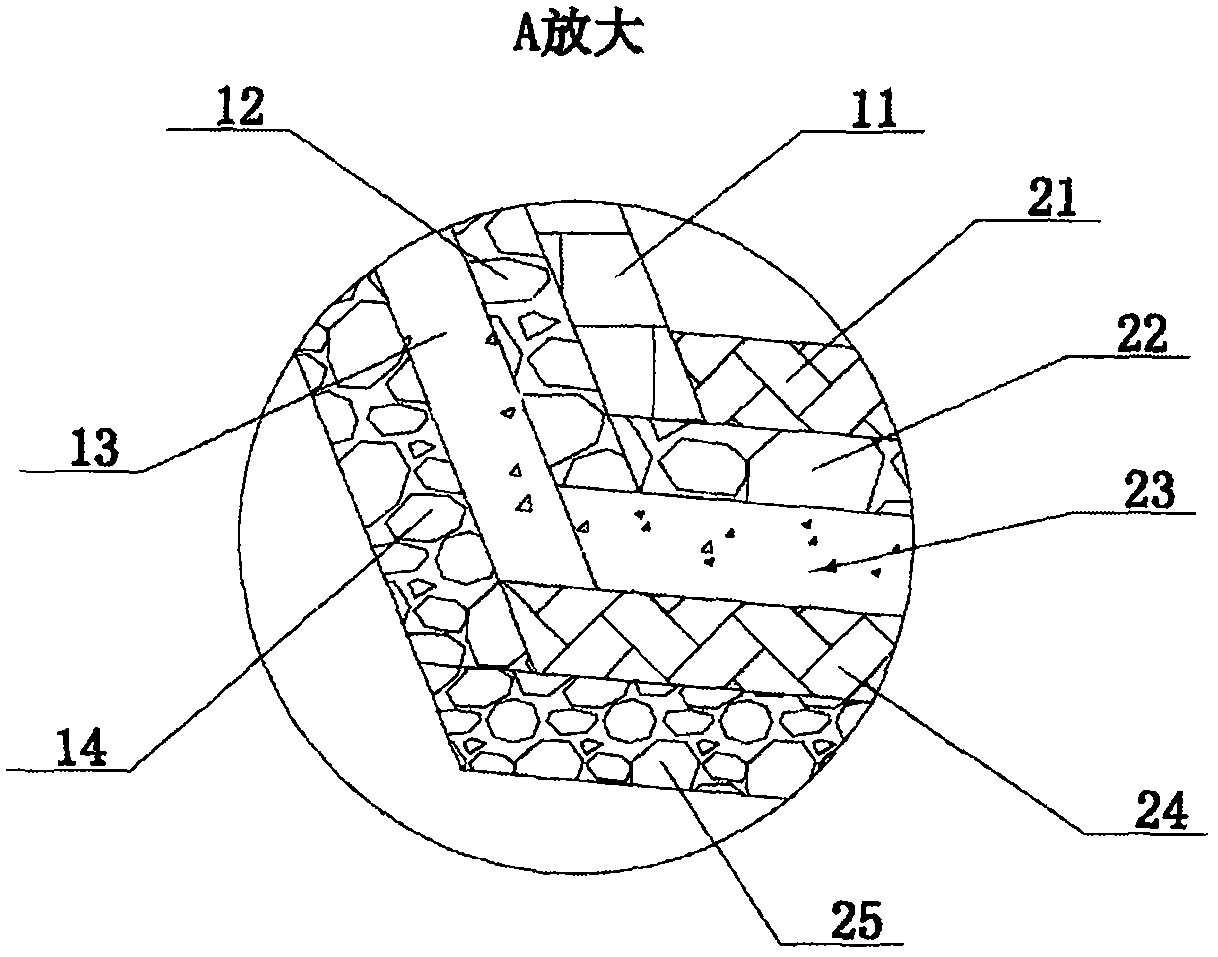

[0018] see Figure 1-Figure 2 As shown, the technical solution adopted in this specific embodiment is: it includes a fermentation tank body 1, a fermentation tank bottom 2, an anchoring ditch 3, an HDPE film 4, a biogas slurry pipeline 5, and a pipeline 6. The fermentation tank body 1 The upper end of the upper end is open, and its lower end is provided with a fermentation tank bottom 2. The cross section of the fermentation tank body 1 and the fermentation tank bottom 2 is a trapezoidal structure, and the anchoring groove 3 is arranged on the four sides of the upper end of the fermentation tank body 1. , the HDPE film 4 covers the opening at the upper end of the fermentation tank body 1 and the inner wall of the fermentation tank body 1 and the bottom 2 of the fermentation tank through the anchoring groove 3 to form a closed structure, and the biogas slurry pipeline 5 is arranged at One side of the fermentation tank body 1, the number of the pipelines 6 is multiple, and they ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com