Water-soluble low-temperature curing polyurethane insulating varnish and its preparation method and application in electrical equipment

A water-soluble, polyurethane technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problem of high curing temperature, and achieve the effect of environmental protection and excellent water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

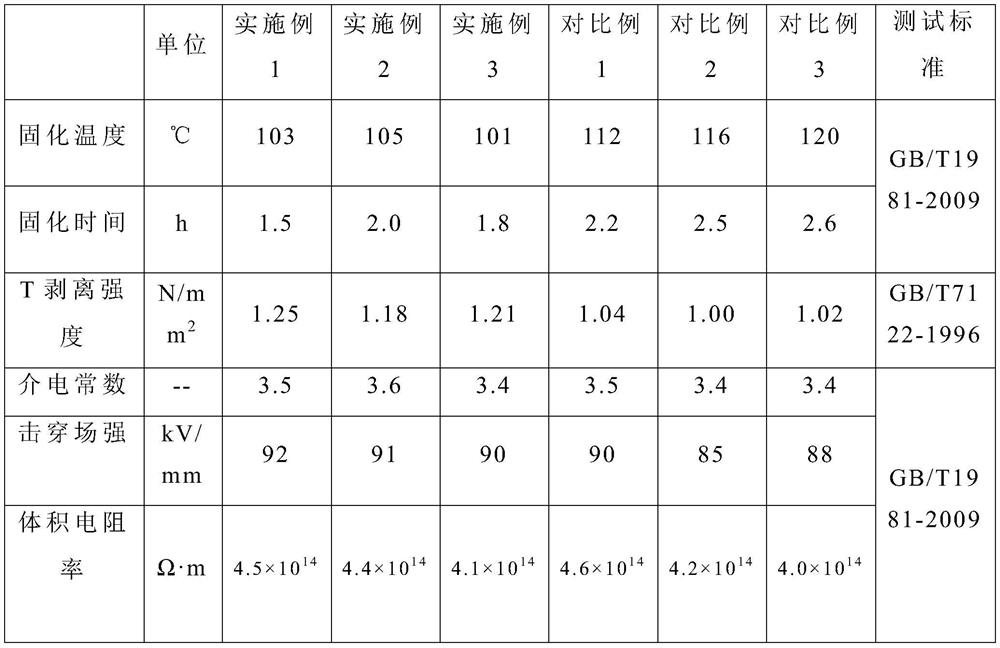

Examples

Embodiment 1

[0032] This embodiment provides a water-soluble low-temperature curing polyurethane insulating varnish. In terms of parts by mass, the raw materials of the polyurethane insulating varnish include 250 parts of polyurethane resin, 8.8 parts of N,N-dimethylethanolamine, 75 parts of 325 resin, two 69 parts of ethylene glycol dimethyl ether, 0.025 parts of strontium cobalt ethoxide, 0.038 parts of 2-hydroxyethyl-1-tin sulfonate, 0.02 parts of nickel 2-pyridyl alcohol, the balance is water, and the solid content is adjusted to about 15%.

[0033] Among them, in parts by mass, the raw materials of the polyurethane resin include 34.3 parts of maleic anhydride, 39.9 parts of glutaric anhydride, 13.4 parts of 1,4-butanediol, 63 parts of diethylene glycol, trimethylolpropane 16 parts, 7.4 parts of glycerin, 8.5 parts of dihydroxypropionic acid, 3 parts of dimethylol butyric acid, 125 parts of diphenylmethane diisocyanate, 84 parts of 1,6-hexamethylene diisocyanate.

[0034] Preparation: ...

Embodiment 2

[0039] This embodiment provides a water-soluble low-temperature curing polyurethane insulating varnish. In terms of parts by mass, the raw materials of the polyurethane insulating varnish include 300 parts of polyurethane resin, 12 parts of N,N-dimethylethanolamine, 99 parts of 5303 resin, two 80 parts of ethylene glycol dimethyl ether, 0.033 parts of strontium cobalt ethoxide, 0.048 parts of 2-hydroxyethyl-1-tin sulfonate, 0.027 parts of nickel 2-pyridine ethoxide, the balance is water, and the solid content is adjusted to about 18%.

[0040] Wherein, in parts by mass, the raw materials of the polyurethane resin include 35 parts of maleic anhydride, 33.3 parts of glutaric anhydride, 24.1 parts of 1,4-butanediol, 85.1 parts of diethylene glycol, trimethylolpropane 26.8 parts, 4.6 parts of glycerin, 9.5 parts of dihydroxypropionic acid, 1.5 parts of dimethylol butyric acid, 200 parts of diphenylmethane diisocyanate, 33.6 parts of 1,6-hexamethylene diisocyanate.

[0041] Prepara...

Embodiment 3

[0046] This embodiment provides a water-soluble low-temperature curing polyurethane insulating varnish. In terms of parts by mass, the raw materials of the polyurethane insulating varnish include 300 parts of polyurethane resin, 15 parts of N,N-dimethylethanolamine, 105 parts of 325 resin, two 62 parts of ethylene glycol dimethyl ether, 0.036 parts of strontium cobalt ethoxide, 0.055 parts of 2-hydroxyethyl-1-tin sulfonate, 0.025 parts of nickel 2-pyridine ethoxide, the balance is water, and the solid content is adjusted to about 20%.

[0047] Wherein, in parts by mass, the raw materials of the polyurethane resin include 36.5 parts of maleic anhydride, 28.3 parts of glutaric anhydride, 29.2 parts of 1,4-butanediol, 46 parts of diethylene glycol, trimethylolpropane 33.5 parts, 13.8 parts of dihydroxypropionic acid, 225 parts of diphenylmethane diisocyanate, 16.8 parts of 1,6-hexamethylene diisocyanate.

[0048] Preparation:

[0049] (1) Weigh each raw material according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com