Method for detecting displacement data of washing machine

A technology of washing machine and data, which is applied in the control device of washing machine, washing device, textile and paper making, etc. It can solve the problems of high cost, affecting user experience, insufficient technical precision and stability, etc., to reduce cost, improve stability, Growth Lifecycle Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

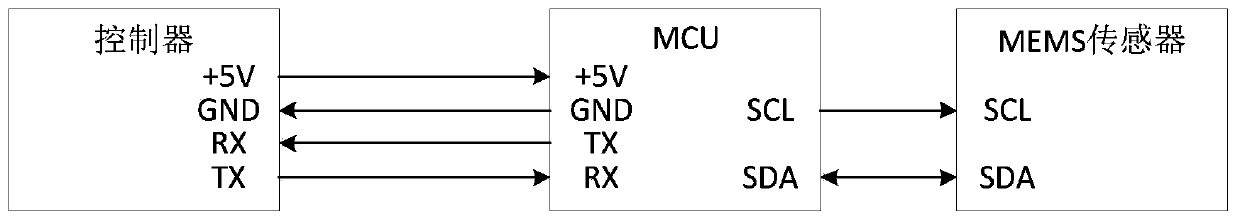

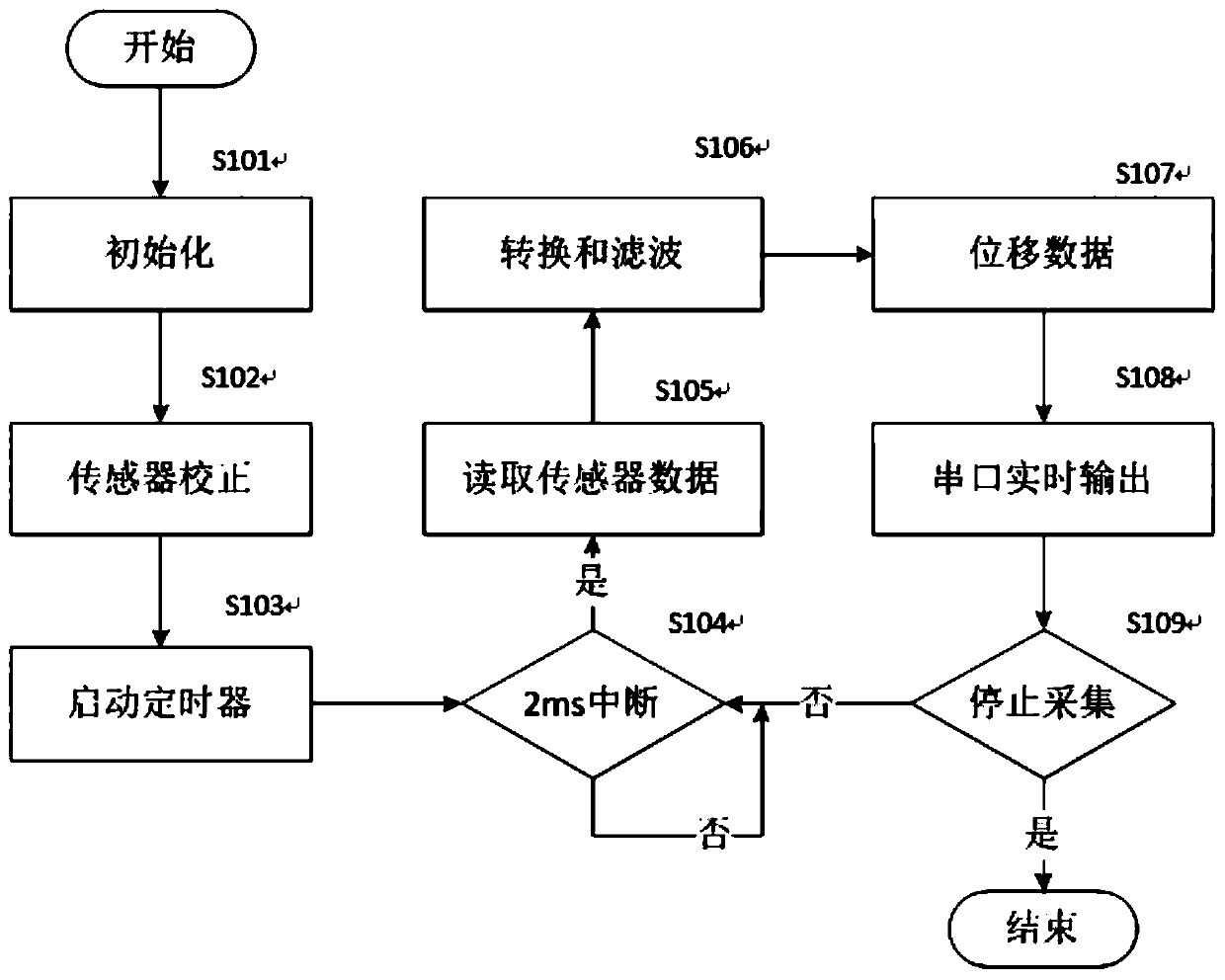

[0023] figure 1 For the circuit structure diagram of the present invention and figure 2 As shown in the program flowchart of the washing machine displacement module of the present invention, the method for detecting the vibration displacement data of the washing machine by the washing machine displacement module of the present invention includes the following steps:

[0024] When the washing machine is powered on, power on the displacement module of the washing machine at the same time;

[0025] MCU microprocessor, MEMS sensor, timer, serial port initialization; such as figure 2 as shown in S101;

[0026] MEMS sensor calibration, after MEMS sensor calibration initialization, collect a certain amount of MEMS sensor acceleration data and take the average as a reference value, and when the MEMS sensor data read later meets certain conditions, the MEMS sensor calibration will be performed again to eliminate the MEMS sensor data. Drift; such as figure 2 Shown in S102;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com