Centralized photovoltaic power station battery assembly defect inspection system based on multi-rotor drone

A multi-rotor UAV and photovoltaic power station technology, applied in the field of centralized photovoltaic power station battery component defect inspection system, can solve the problems of increased pressure on maintenance personnel, tedious and time-consuming, and different ways of presenting data, etc., to achieve detection efficiency Improvement, high degree of automation, and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

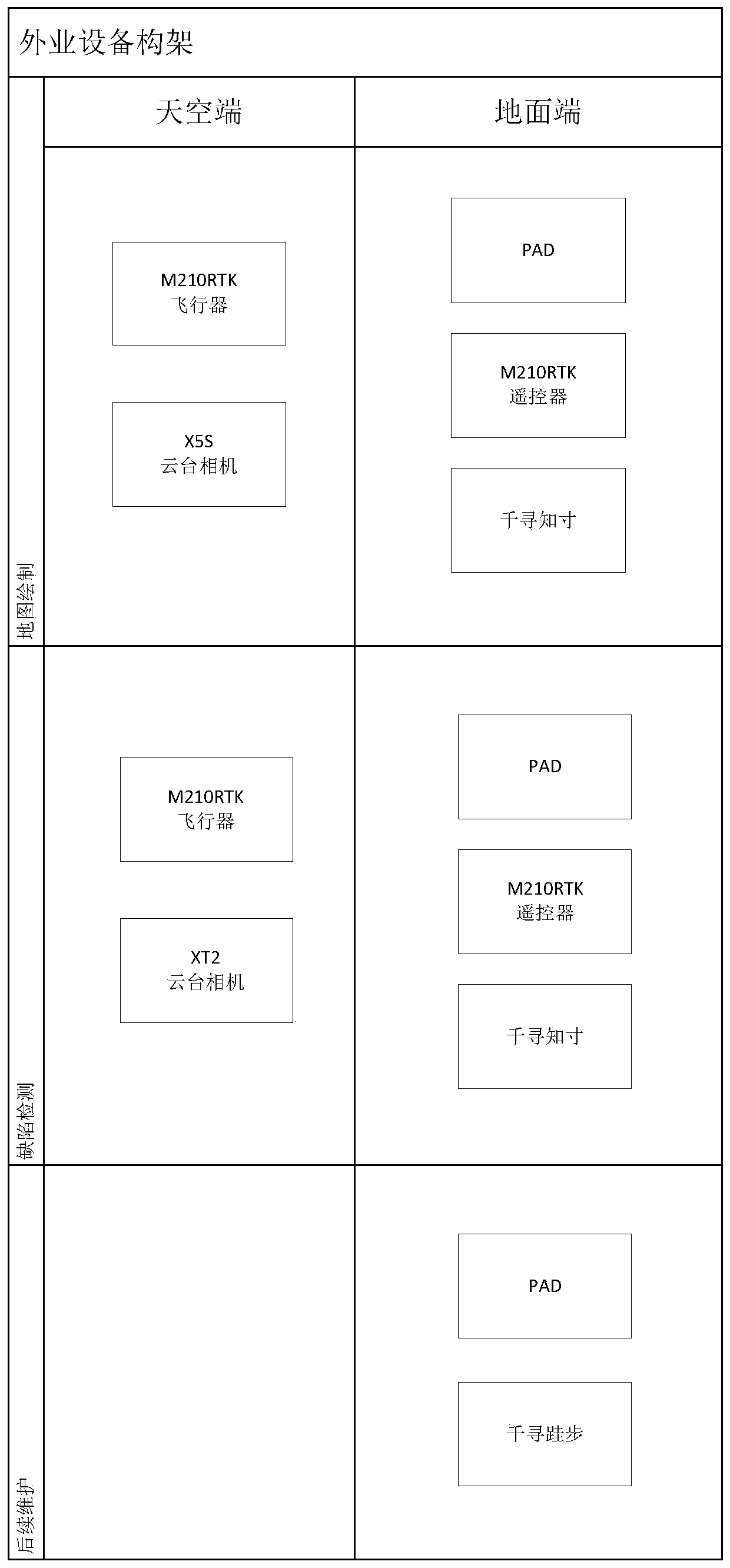

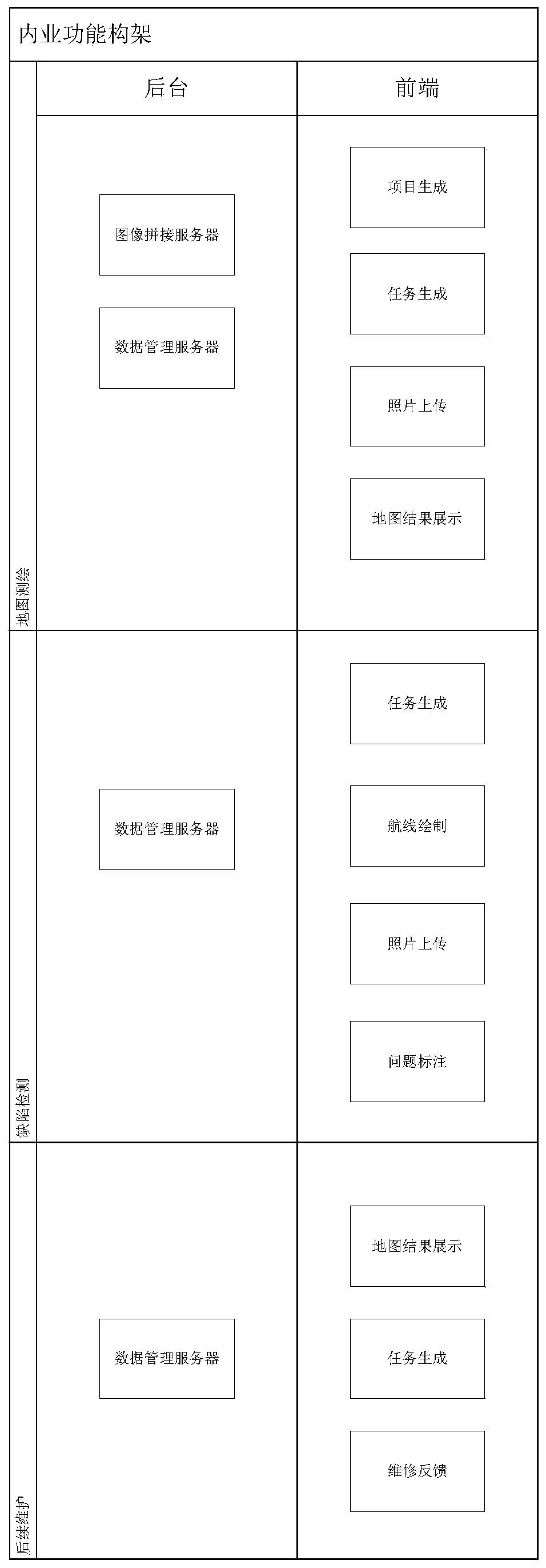

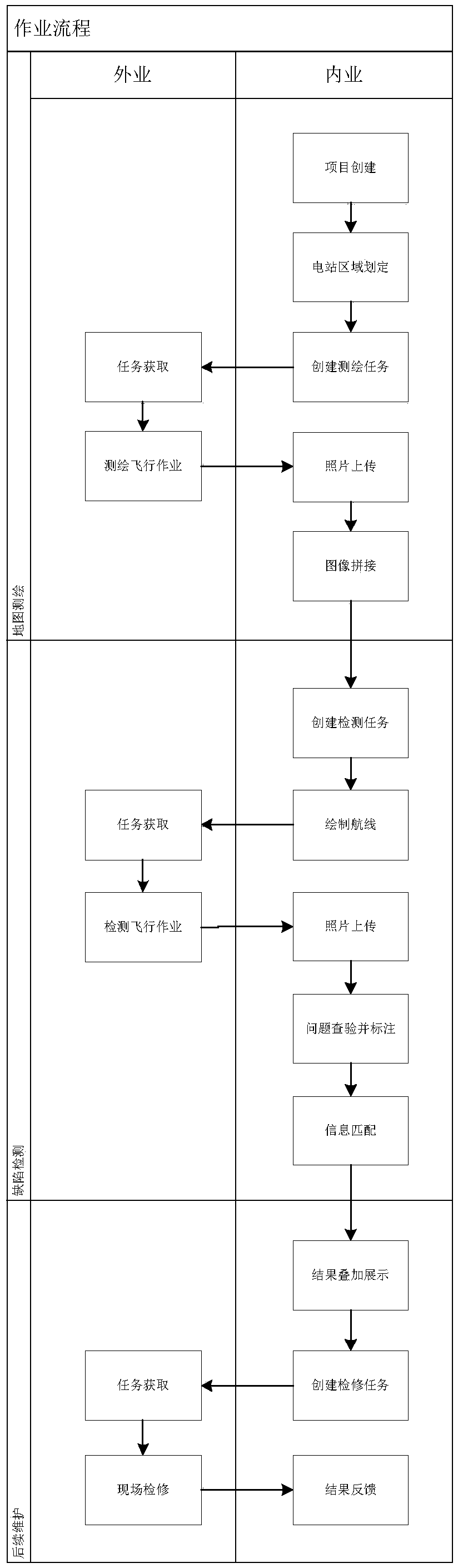

[0036] refer to Figure 4 combine figure 1 and figure 2 , a centralized defect inspection system for photovoltaic power station battery components based on multi-rotor drones, including field equipment framework 01 and office functional framework 02. The field equipment framework includes drone 010, PAD011, and X5S pan-tilt camera 012, XT2 pan / tilt camera 013, UAV remote control 014 and PAD can be connected to the Cors base station 015 at Qianxun location. Office functional architecture 02 includes front-end 021 and background 022. The functions of front-end 021 are displayed in the form of web p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com