Calibration device for fiber Bragg grating vibration sensor and uncertainty analysis method of calibration device

A technology of vibration sensor and optical fiber grating, which is applied to measuring devices, instruments, and measuring ultrasonic/sonic/infrasonic waves, etc. It can solve problems such as difficult operation, cumbersome experimental process, and high experimental difficulty, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

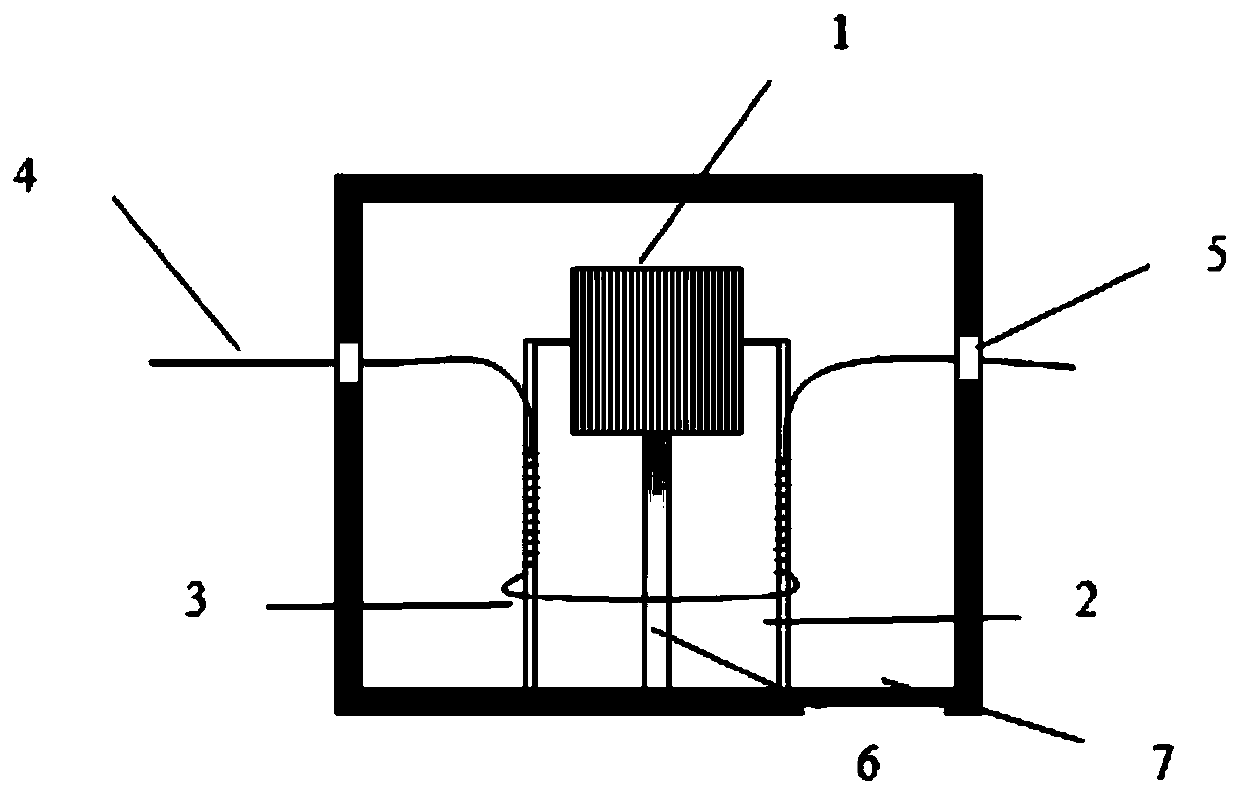

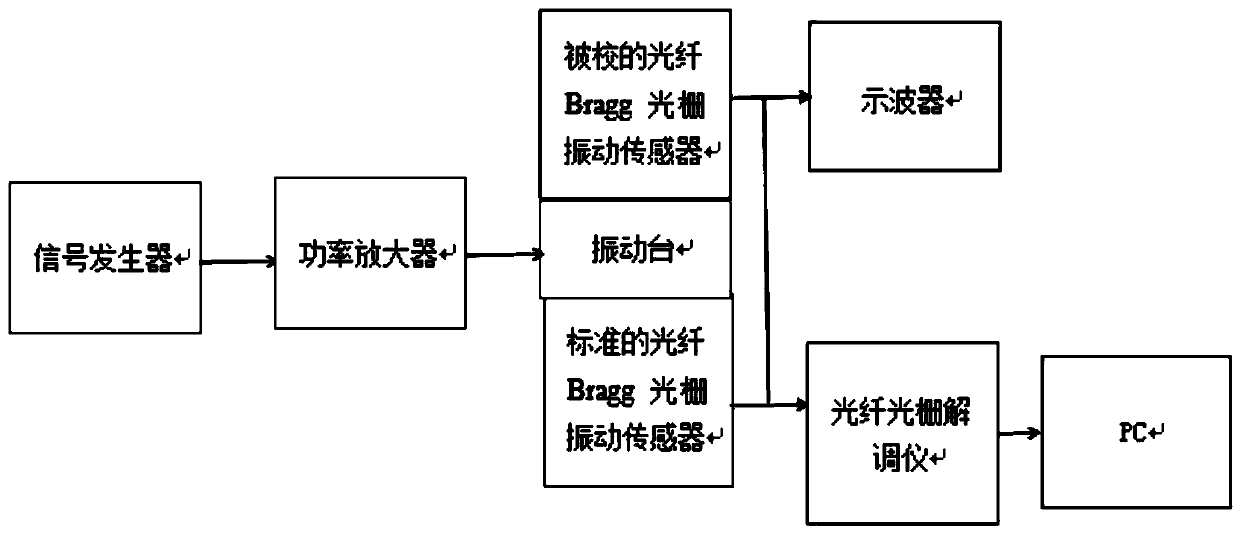

[0015] Embodiment 1: as Figure 1-2 As shown, a fiber Bragg grating vibration sensor calibration device includes mass block 1, elastic steel sheet I2, elastic steel sheet II3, steel pipe 6, base 7, fiber Bragg grating FBG I4, fiber Bragg grating FBG II5, vibration table, and signal generator , power amplifier, oscilloscope, fiber grating demodulator, PC; the quality block 1 is fixed on the top of the steel pipe 6, the bottom of the steel pipe 6 is fixed on the base 7, and the elastic steel sheet I2 and elastic steel sheet II3 are placed on the left and right sides of the steel pipe, The lower end is fixed on the base 7, the upper end is connected and fixed to the left and right ends of the mass block 1, the fiber Bragg grating FBGⅠ4 and the fiber Bragg grating FBGⅡ5 are welded in series and pasted on the elastic steel sheet I2 and the elastic steel sheet II3 respectively, and the mass block 1 , elastic steel sheet Ⅰ2, elastic steel sheet Ⅱ3, steel pipe 6, base 7, fiber Bragg g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com