Power industry cable deicing device

A technology of electric power industry and walking device, which is applied in the installation of cables, electrical components, overhead installation, etc. It can solve the problems of cutter ice stuck, high risk, power failure, etc., and achieve the effect of preventing internal accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

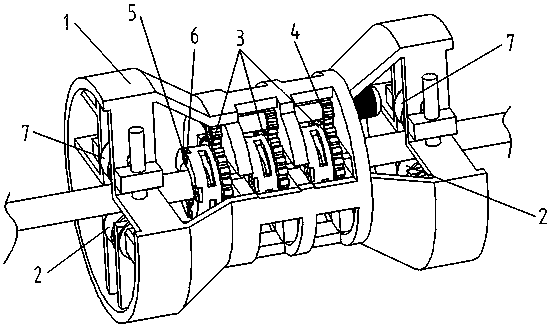

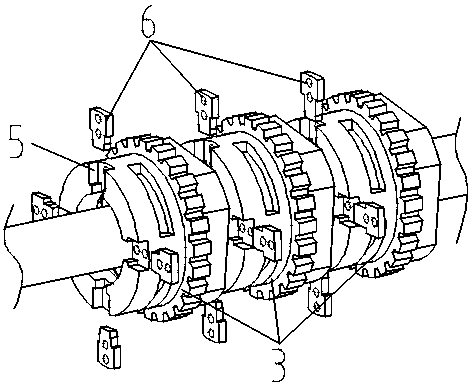

[0041] A kind of electric power industry cable deicing device of this embodiment, such as figure 1 with figure 2 As shown, it includes a mounting frame 1 set on the outside of the cable. The two ends of the mounting frame 1 are symmetrically provided with a running device 2 and a tensioning device 7. The inside of the mounting frame 1 is coaxially rotated and installed along the length direction of the cable. There are three turrets 3, the center of the turret 3 is provided with a through hole for cables to pass through, and the inside of the installation frame 1 is also equipped with a rotating device 4 that drives the turret 3 to rotate; one end of the turret 3 A number of installation grooves 5 facing the cables are arranged in a circumferential array, and deicing knives 6 are clamped in the installation grooves 5, and the distance between the deicing knives 6 arranged on the three turrets 3 and the cables moves along the The direction becomes shorter in turn.

[0042] T...

Embodiment 2

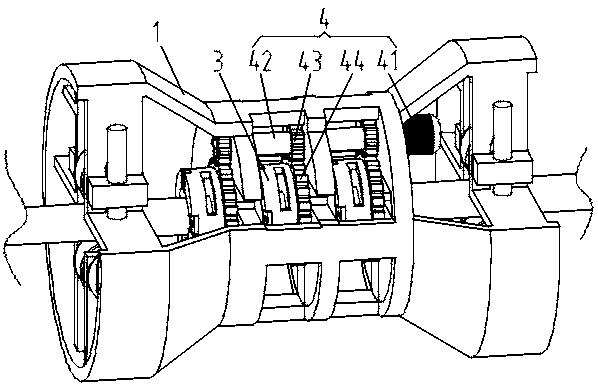

[0046] This embodiment is further optimized on the basis of embodiment 1, such as image 3 As shown, the rotating device 4 includes a rotating motor 41, a drive shaft 42, a drive gear 43, and a ring gear 44. The drive shaft 42 is installed on the inside of the installation frame 1 for rotation along the cable length direction, and the drive shaft 42 is located on the turret 3, one end of the drive shaft 42 is connected to the output end of the rotating motor 41; the outer side of the turret 3 is fitted with a ring gear 44, and the drive shaft 42 is provided with a drive gear meshed with the ring gear 44 43.

[0047] When the ice layer frozen on the outside of the cable was thicker, the deicing cutter 6 on each turret 3 required a larger cutting force when removing the ice layer. One side of the frame 3 is independently provided with a group of rotating devices 4 for driving the turret 3 to rotate. The top of the inner side of the mounting frame 1 is respectively provided wit...

Embodiment 3

[0051] This embodiment is further optimized on the basis of above-mentioned embodiment 1 or 2, such as Figure 4 with Figure 5 As shown, the interior of the installation frame 1 is coaxially provided with three sets of installation disks 11 along the length direction of the cable, and the center of the installation disk 11 is provided with a through hole for the cable to pass through; one side of the installation disk 11 is provided with There is a rotating boss, and the outer side of the rotating boss is provided with an annular rotating groove 12 along the circumferential direction, and a rotating ring 13 is arranged in the annular rotating groove 12, and a number of locking rings 13 are arranged on the outer side of the rotating ring 13 along the circumferential direction. Threaded hole 14; the turret 3 is sleeved on the outside of the swivel 13, and the position corresponding to the locking threaded hole 14 along the circumferential direction is provided with a fixing hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com