Motor control device

A motor control and controller technology, applied in motor control, AC motor control, motor speed or torque control, etc., can solve problems such as large surge, inability to achieve stable control, and difficulty in obtaining a three-phase motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

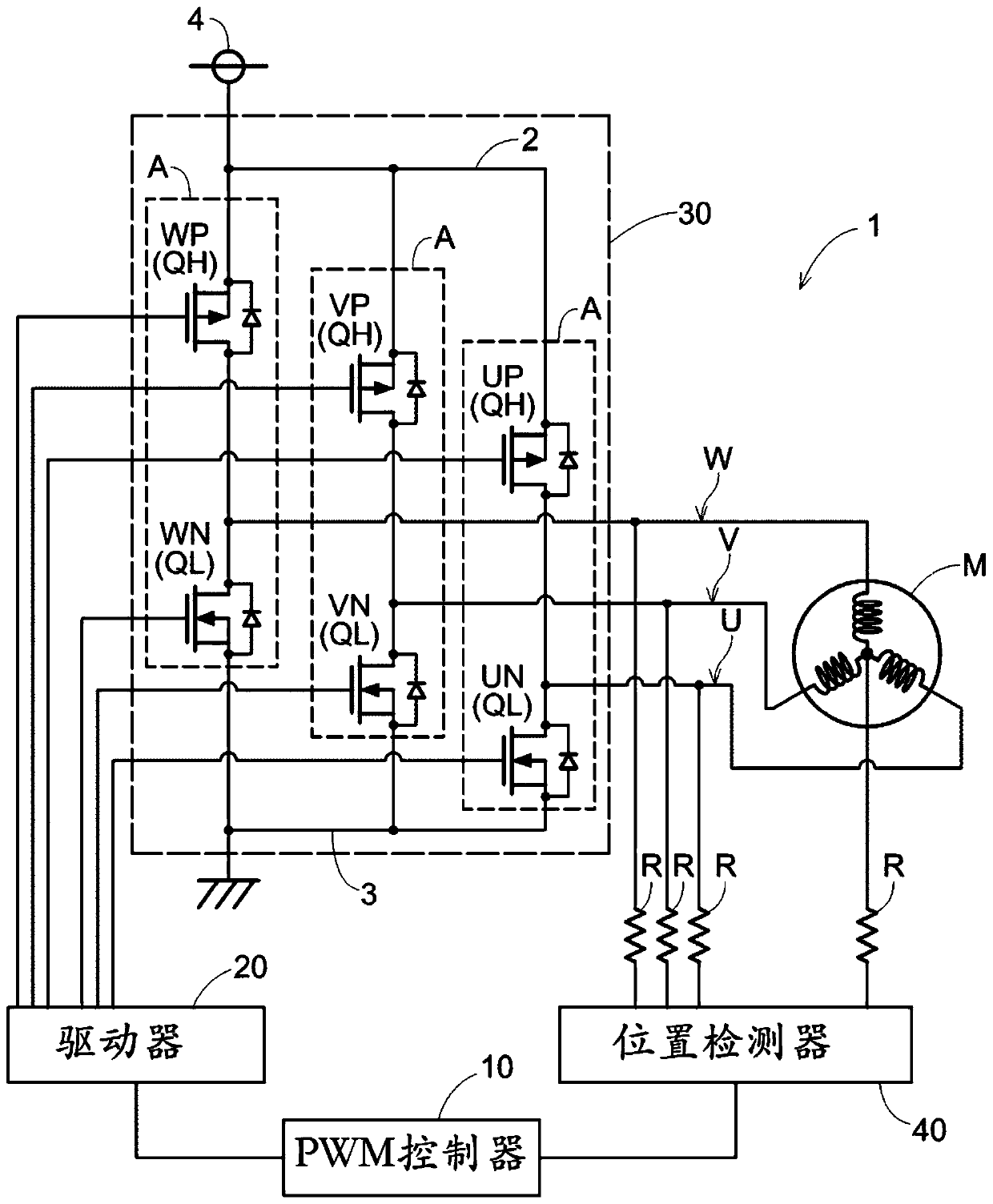

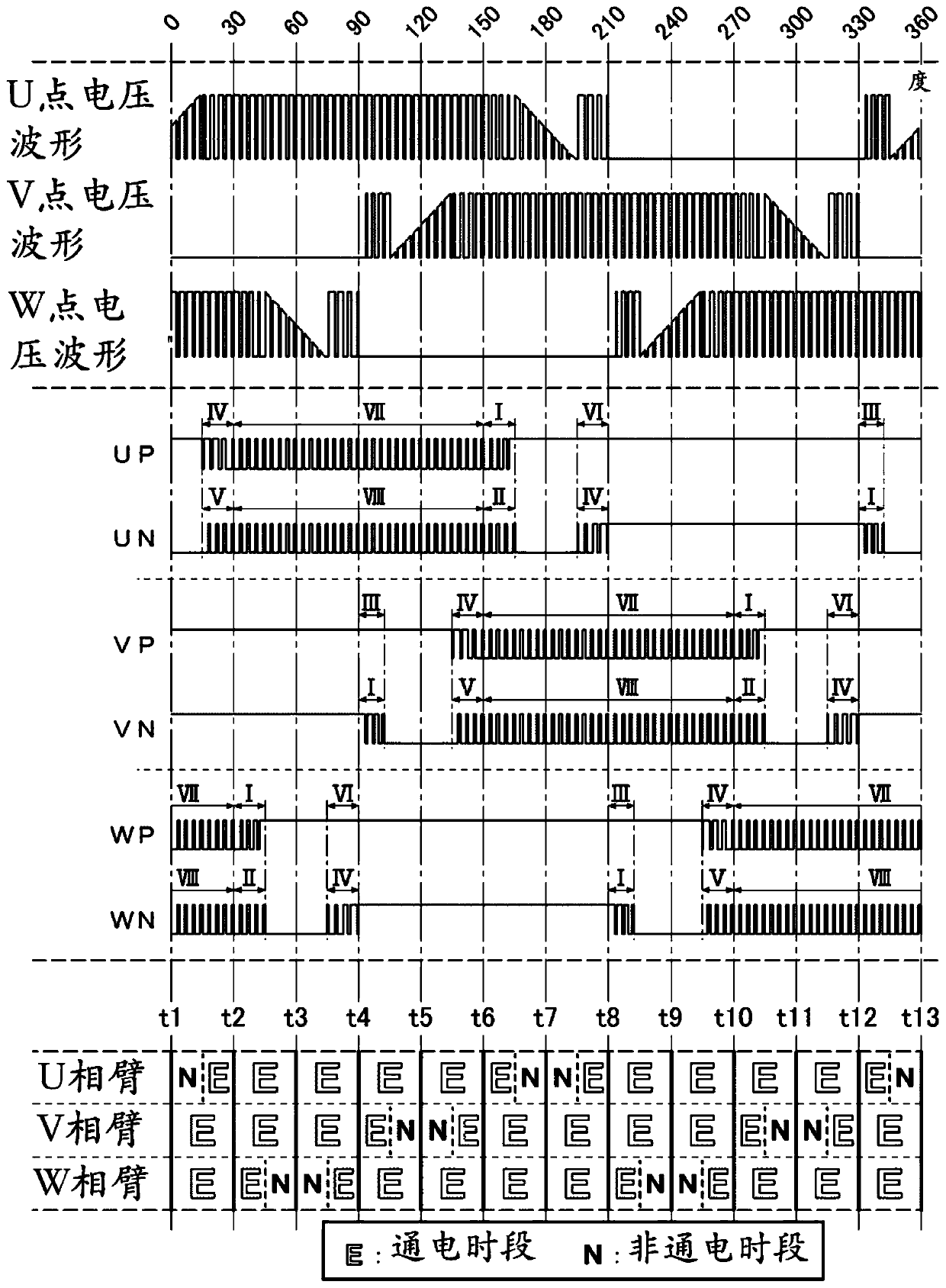

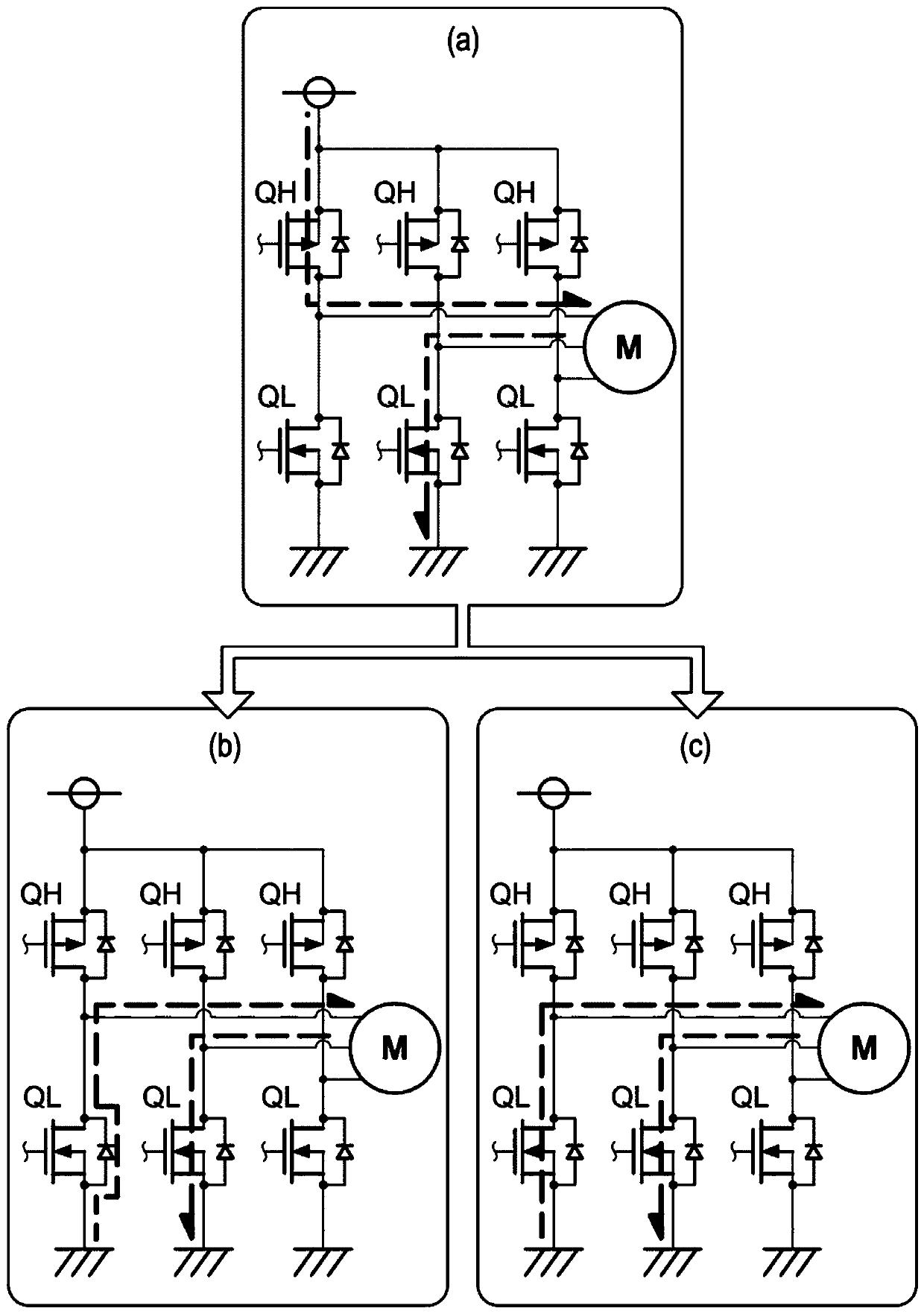

[0019] The motor control device disclosed here is configured to have a function of suppressing a surge regardless of the rotational speed of the three-phase motor. The motor control device 1 according to the embodiment will be described below.

[0020] figure 1 It is a block diagram schematically illustrating the configuration of the motor control device 1 . The motor control device 1 is configured to include a PWM controller 10 , a driver 20 , an inverter 30 , and a position detector 40 .

[0021] The PWM controller 10 generates a PWM signal, and performs PWM control on an inverter 30 described below. PWM control via PWM signals is known in the related art, so details are not repeated here.

[0022] The driver 20 is provided between the PWM controller 10 and the inverter 30 , and a PWM signal generated by the PWM controller 10 is input to the driver 20 . The driver 20 improves the driving capability of the input PWM signal, and outputs the PWM signal to the inverter 30 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com