Spiral flow self-desilting type desilting filter tank

A technology of self-discharging and sedimentation tank, applied in the direction of filtration loop, filtration separation, sedimentation tank, etc., can solve the problems of inability to meet the requirements of irrigation, poor sedimentation effect, and insufficient sedimentation, and achieve simple structure, Improve sand removal efficiency, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

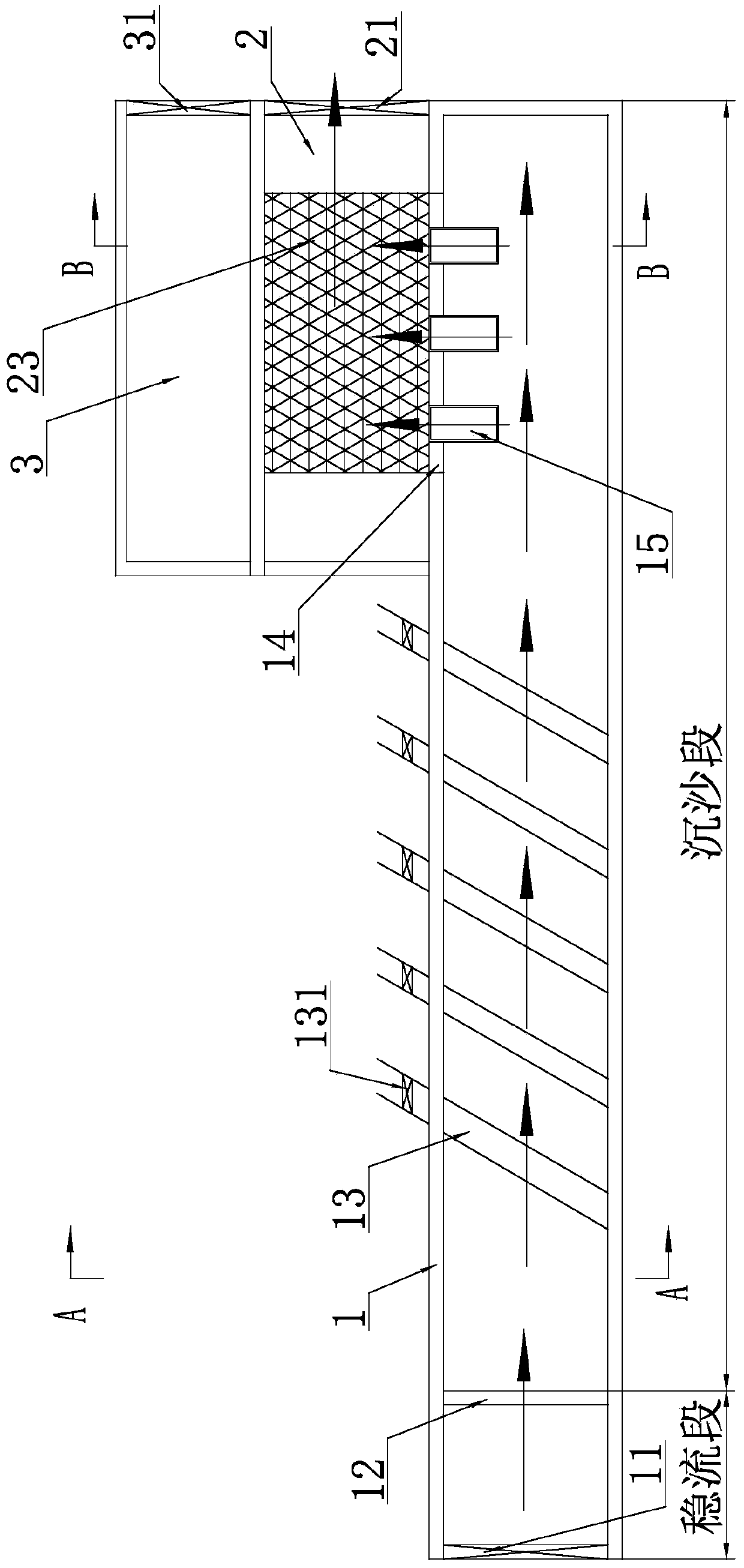

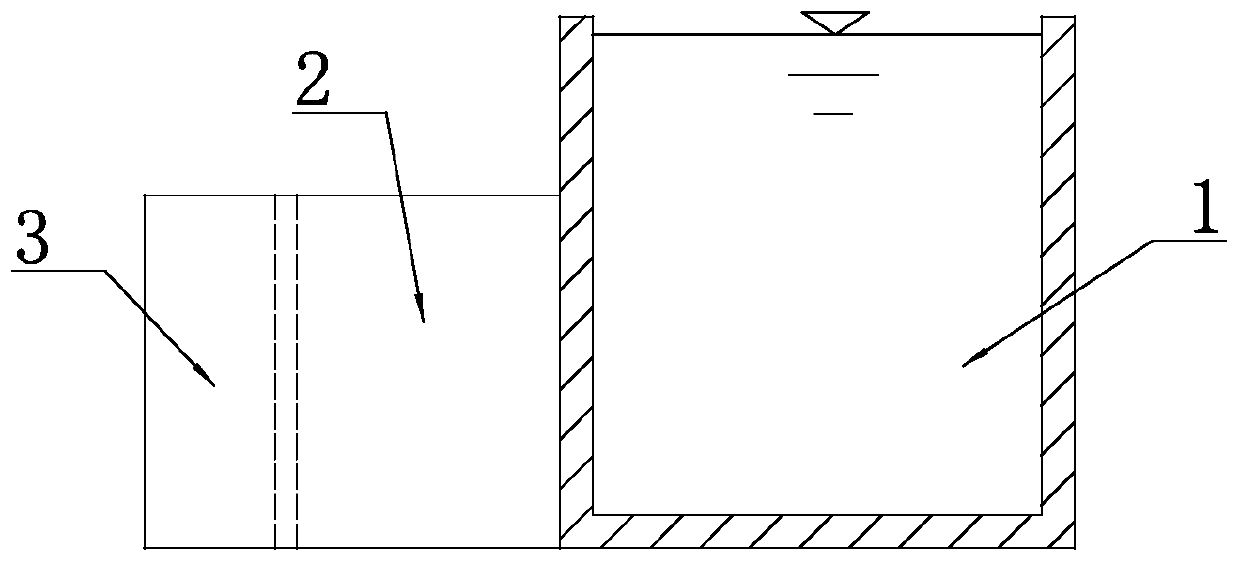

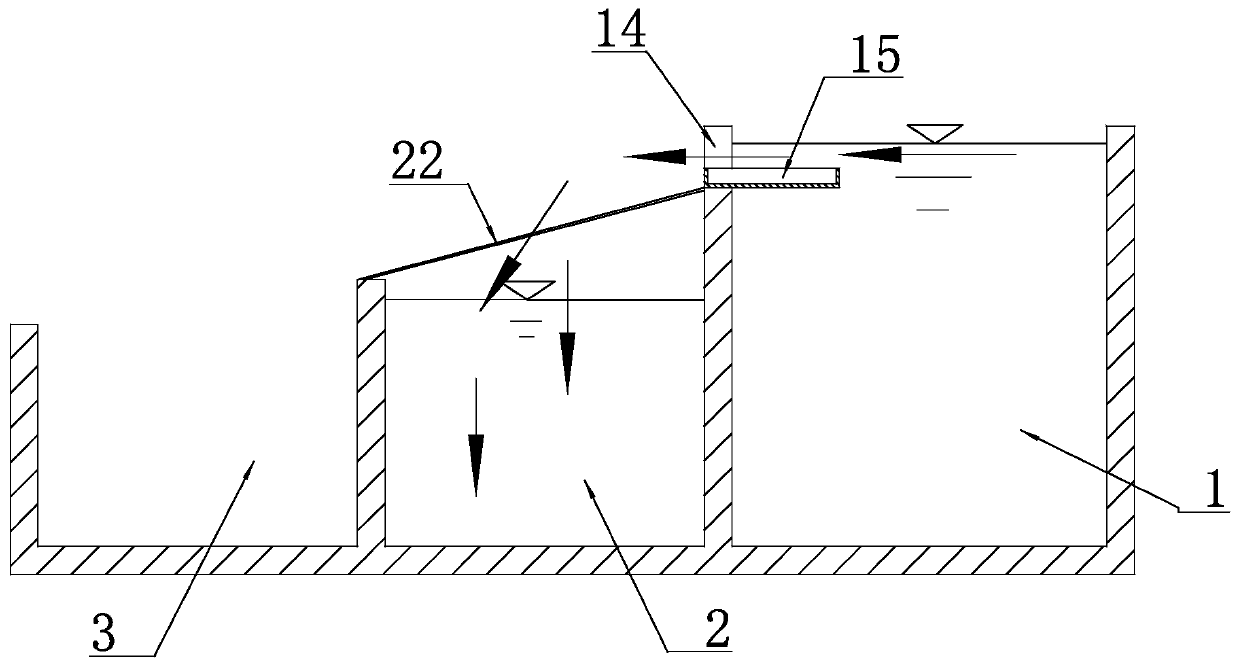

[0036] Such as figure 1 As shown, a spiral flow self-discharging sand filter tank includes a grit chamber 1, and the tail end of the grit chamber 1 is provided with a clear water pool 2, and the described grit chamber 1 and the clean water pool 2 jointly form a L-shaped structure, and if figure 2 As shown, the height of the clear water tank 2 is less than the height of the grit chamber 1. The front end of the grit chamber 1 is provided with a water inlet gate 11 , and the rear end of the clean water tank 2 is provided with a water outlet gate 21 . The wall between the grit chamber 1 and the clean water pond 2 is provided with a first gap 14, and the water in the grit chamber 1 overflows laterally into the clean water pond 2 through the first gap 14, And flow out through the outlet gate 21 of the clear water pool 2 for farmland irrigation.

[0037] Such as figure 1 As shown, the front end of the grit chamber 1 is provided with a regulating plate 12 , and the regulating pla...

Embodiment 2

[0057] Such as Figure 8 As shown, the sand discharge vortex 13 is perpendicular to the axis of the grit chamber 1, one end of the sand discharge vortex 13 extends to the outside of the grit chamber 1, and the sand discharge vortex 13 One end extending to the outside of the grit chamber 1 is provided with a sand discharge valve 131, and the height of the end with the sand discharge valve 131 is lower than that of the other end, and the rest of the structure is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com