A Coating Guide Floating Mechanism Used in Overhead Bare Wire Coating Device

A technology of coating device and floating mechanism, applied in overhead line/cable equipment, device for coating liquid on the surface, coating, etc., can solve the problem of failing to meet the requirements of coating technology and insulating electrical performance indicators, and unable to guarantee the thickness of insulating materials. Uniformity, inability to maintain vertical relationship, etc., to eliminate adverse effects, prevent reverse leakage, and reduce moving resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

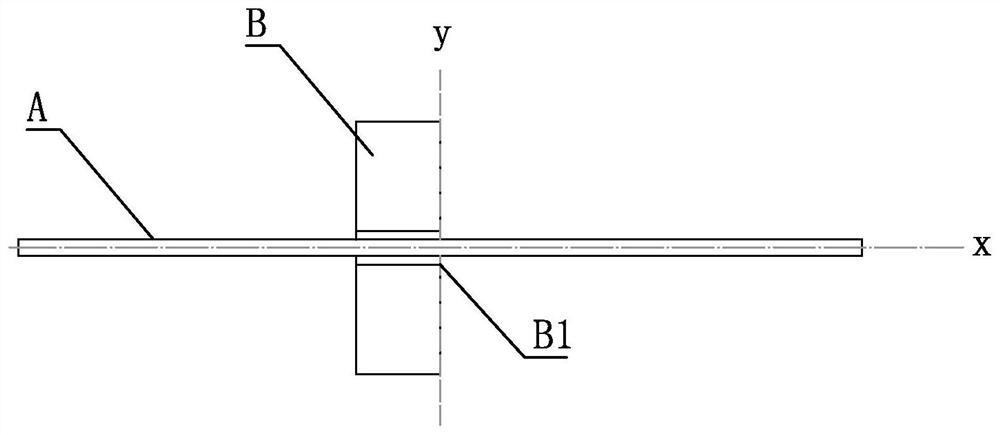

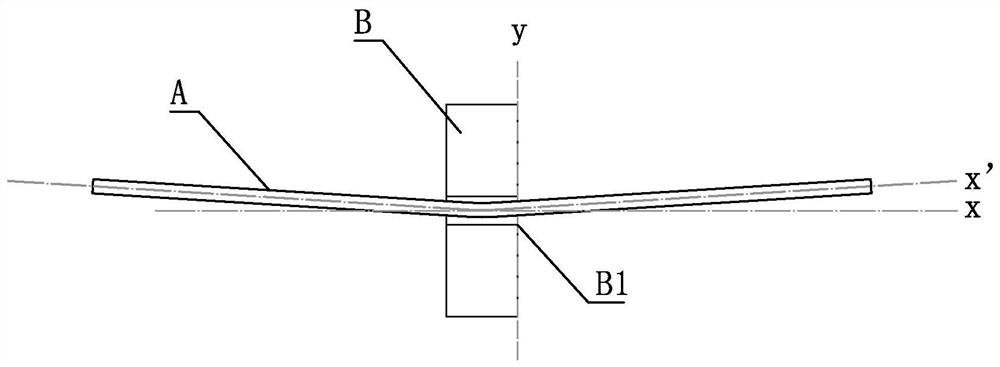

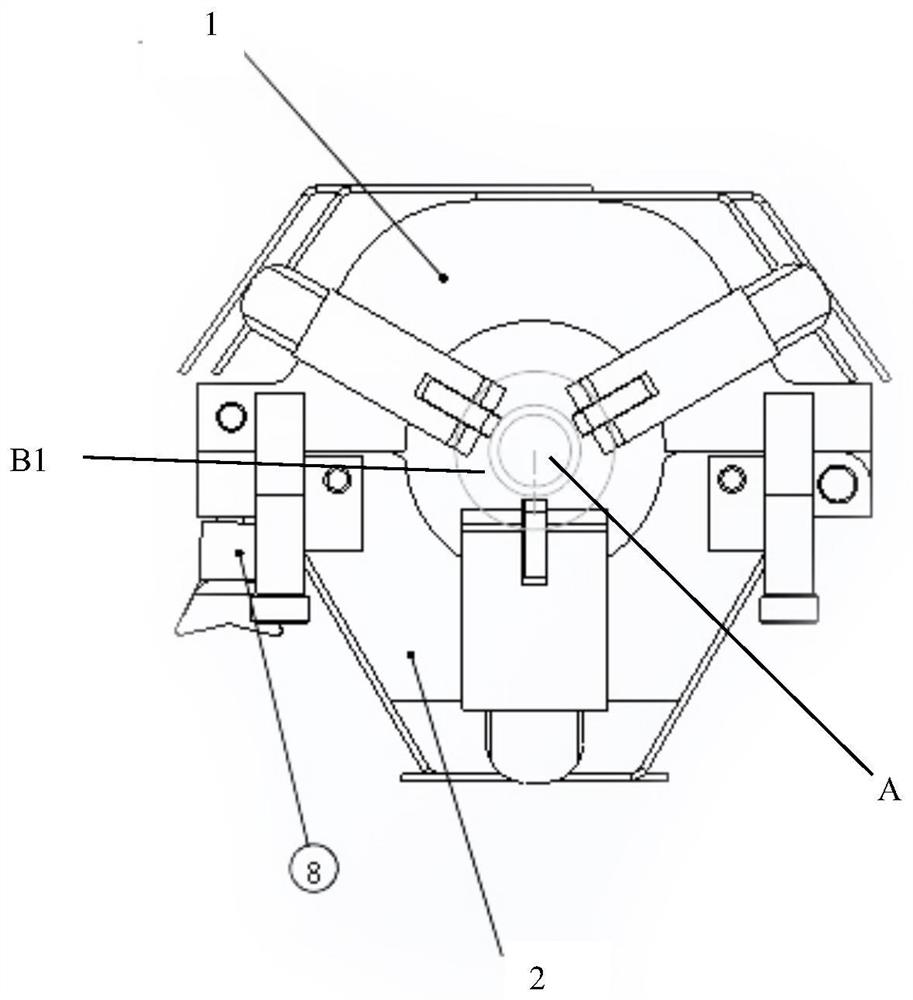

[0040] image 3 neutralize Figure 4 Among them, the technical solution of the present invention provides a coating guiding floating mechanism for an overhead bare wire coating device, and its invention points are:

[0041] A ring-shaped guiding floating mechanism composed of an upper pressing part 1 and a lower pressing part 2 is provided;

[0042] One end of the upper pressing piece and the lower pressing piece are hinged, and the other end is buckled through the movable connecting plate 8 to form a snap-fit ring structure in which the overhead wire to be coated can be clamped penetratingly.

[0043] Obviously, the diameter of the inner circle of the snap-fit ring structure must be greater than the diameter of the wire outlet of the coating assembly in the coating device.

[0044] On one side of the snap-fit ring structure, a rigid centering co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com