Wear-resistant wringing roller

A technology of squeezing rollers and roll bodies, which is applied in workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve the problems of short life of squeezing rollers, poor wear resistance, and failure of bearing lubrication, so as to ensure surface quality, The effect of reducing production cost and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

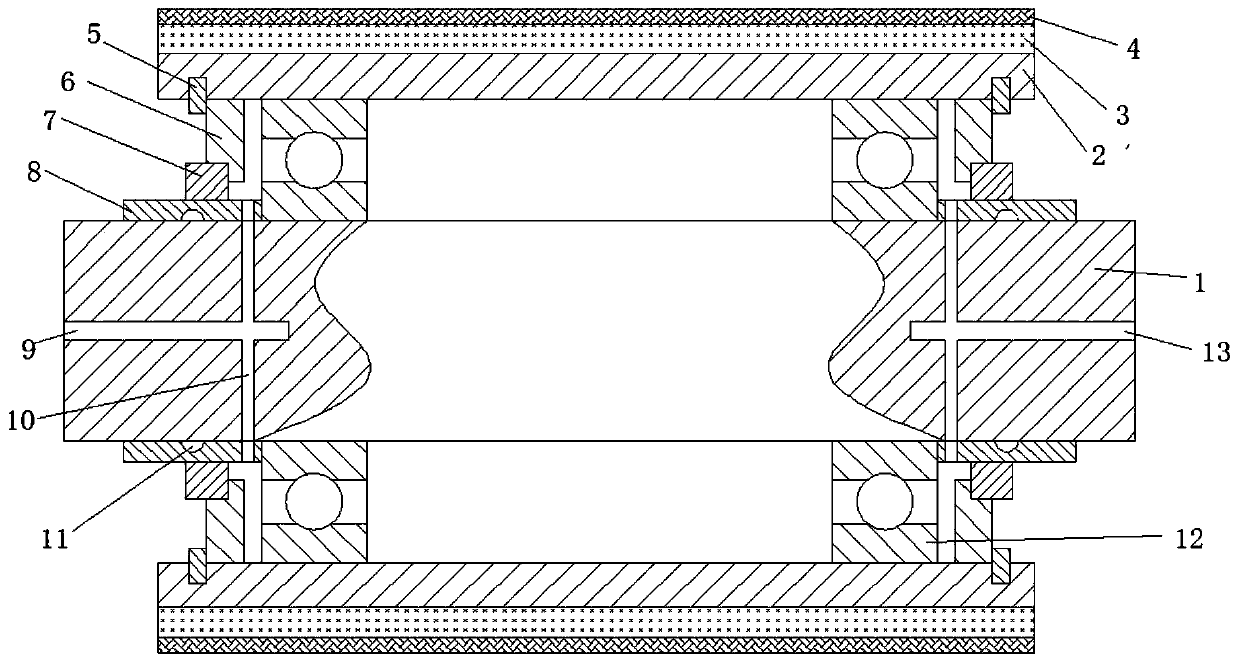

[0039] figure 1 A schematic structural view of the wear-resistant squeezing roller according to this embodiment is shown.

[0040] Such as figure 1 As shown, the two ends of the roll body 2 made of rolled steel are sleeved on the central shaft 1 made of alloy steel through bearings 12 respectively, and the cushion layer is wrapped on the outer circumference of the roll body 2, including a fluorine rubber layer 3 and a polyurethane layer 4 , the fluororubber layer 3 is located between the roller body 2 and the polyurethane layer 4, the thickness of the fluororubber layer 3 is 4 mm, the thickness of the polyurethane layer 4 is 2 mm, and the sealing structure is arranged at both ends of the roller body 2 for sealing the roller body 2 Seals are formed between both ends of the roller body 2 and the central shaft 1, including a positioning sleeve 8, an end cover 6, a retaining ring 5 and a skeleton oil seal 7. The positioning sleeve 8 is set on the central shaft 1 outside the rolle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com