Clamp for integrated machining of heavy gas turbine movable blade tenon and integrated machining method of heavy gas turbine movable blade tenon

A gas turbine and integrated processing technology, which is applied in the direction of manufacturing tools, metal processing equipment, grinding workpiece supports, etc., can solve the problems of large processing errors, long time consumption, and high processing precision, so as to improve processing accuracy, reduce processing time, The effect of meeting the assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

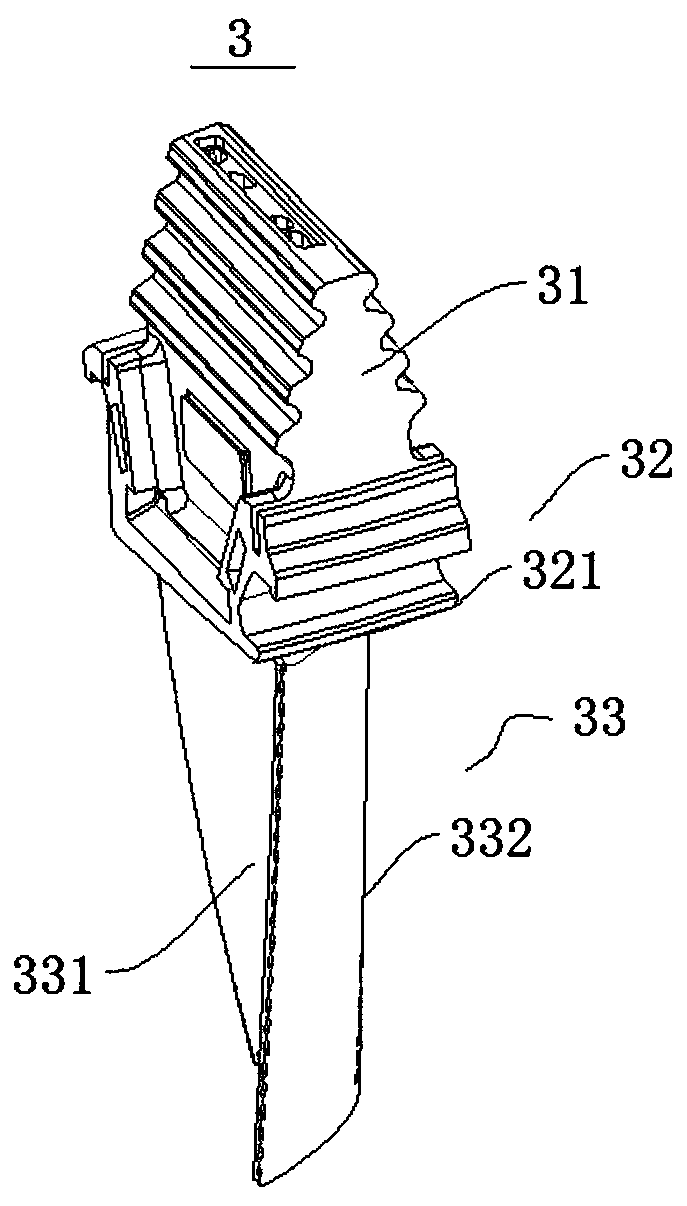

[0037] refer to image 3 As shown, the existing moving blade 3 is often composed of tenon 31, extension root 32 and blade body 33, wherein the tenon 31 has multiple processed and formed surfaces for later assembly with other parts, so its processing The precision requirement is high. The extension root 32 is located between the tenon 31 and the blade body 33. The protruding part on both sides is usually called the extension root wing 321. The blade body 33 is relatively twisted between two adjacent sections and the cross-sectional area is given by For twisted blades with variable cross-sections that gradually increase from the root to the top, the concave side of the blade body 33 is usually called the pressure side 331 , and the convex side of the blade body 33 is called the suction side 332 .

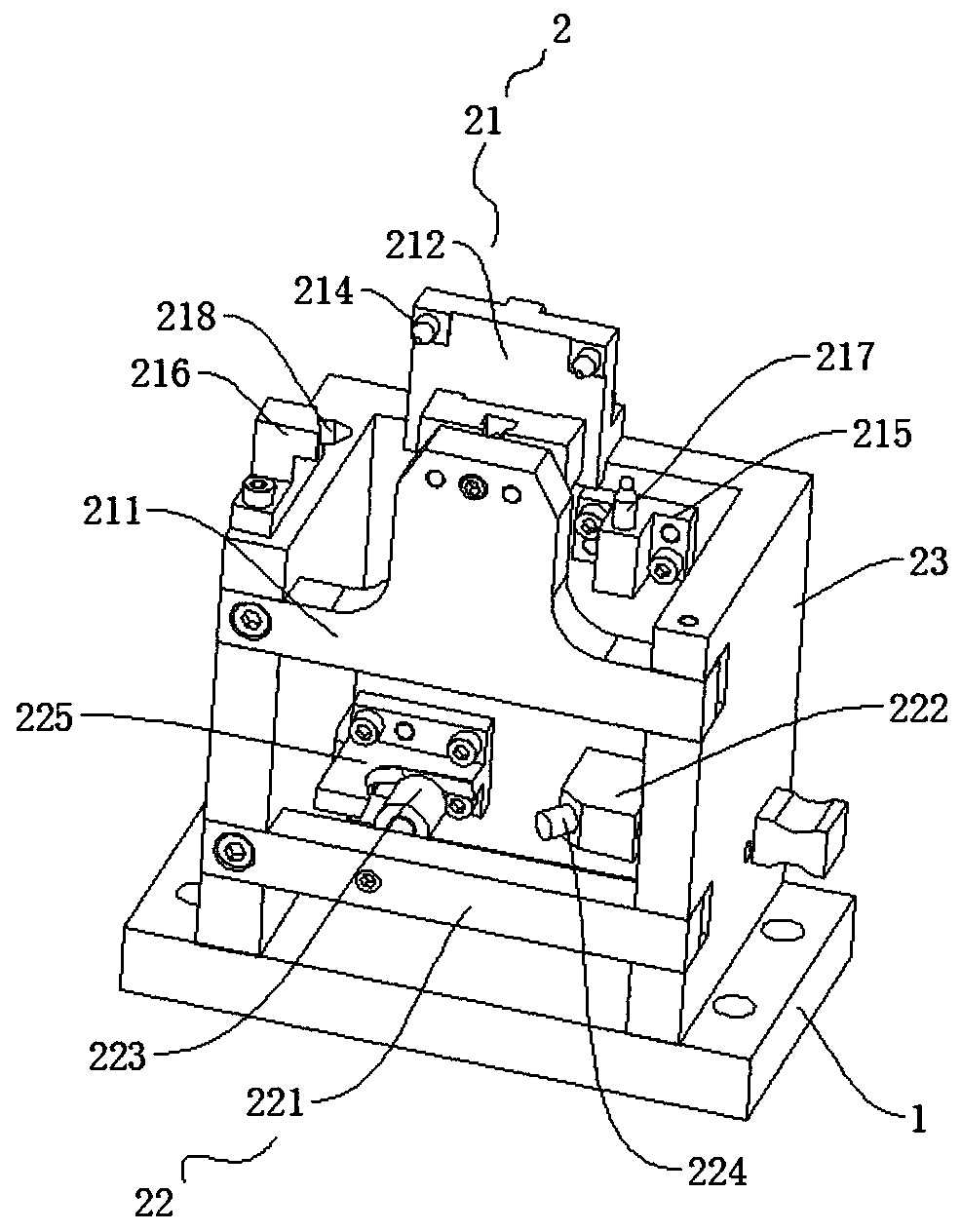

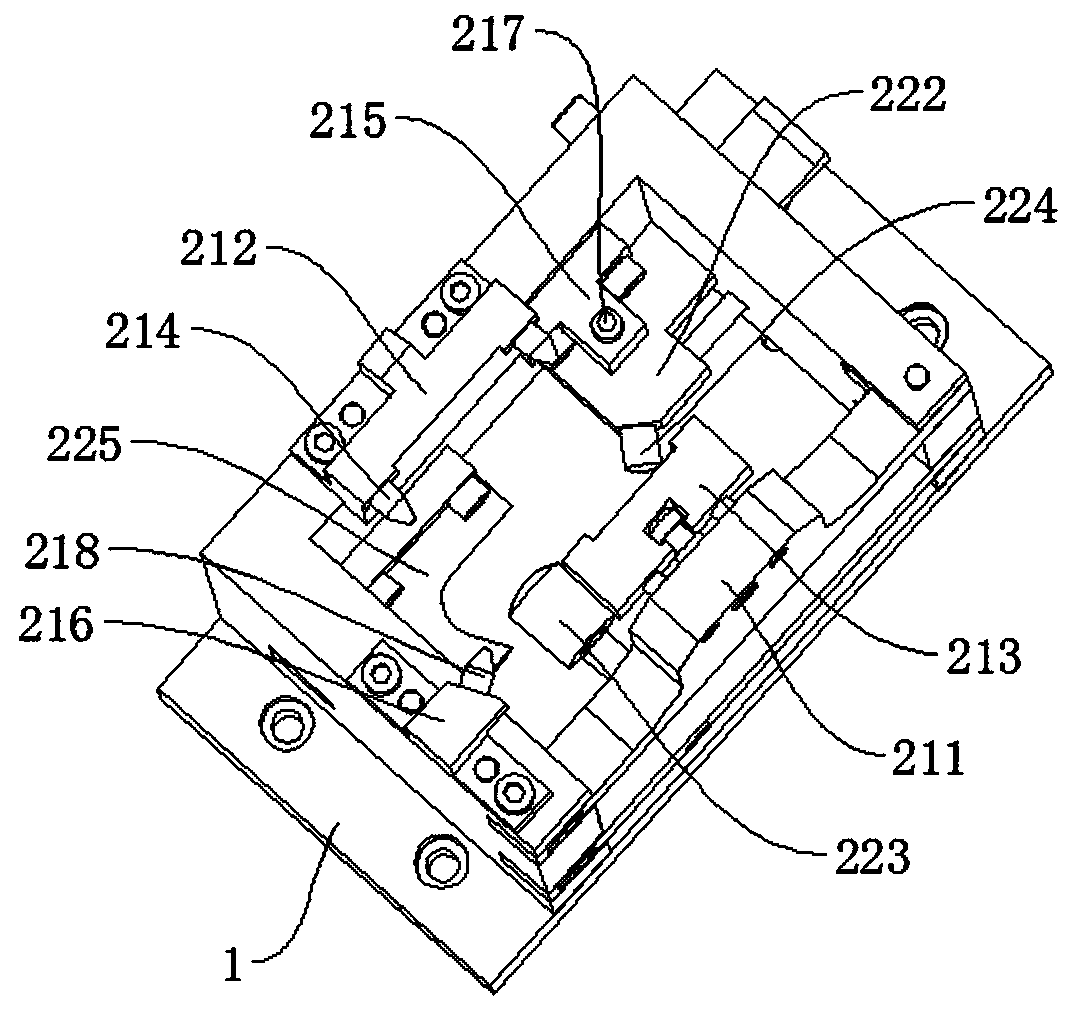

[0038] In order to fix the moving blade 3 in the process of processing the tenon 31 of the moving blade 3 and prevent it from shifting, refer to figure 1 and figure 2 , this embodi...

Embodiment 2

[0046] The present invention provides a heavy-duty gas turbine rotor blade tenon integrated processing method. The movable blade 3 is fixed by using the fixture for the heavy-duty gas turbine rotor blade integrated processing of the above-mentioned embodiment 1, and the fixed rotor blade 3 refers to Figure 4 and Figure 5 As shown, the processing method includes the following processing steps:

[0047] S1. Place the moving blade 3 to be processed on the jig so that the tenon 31 to be processed of the moving blade 3 is facing upwards, so as to facilitate the subsequent processing of the tenon 31;

[0048] S2. Fix the extension root 32 of the moving blade 3 through the first clamping assembly 21, and fix the blade body 33 of the moving blade 3 through the second clamping assembly 22, so as to prevent the machining error caused by the deviation of the moving blade 3 during the processing;

[0049] S3. Fix the fixture together with the moving blade 3 on the working table of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com