Two-rotating two-moving parallel machining swing head mechanism

A swing head and parallel technology, applied in the field of mechanical processing, can solve the problems of large space occupied by the drive rod, poor motion state, and singularity of the layout form, etc., and achieve the effect of compact structure, good dynamic performance, and solving singularity problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

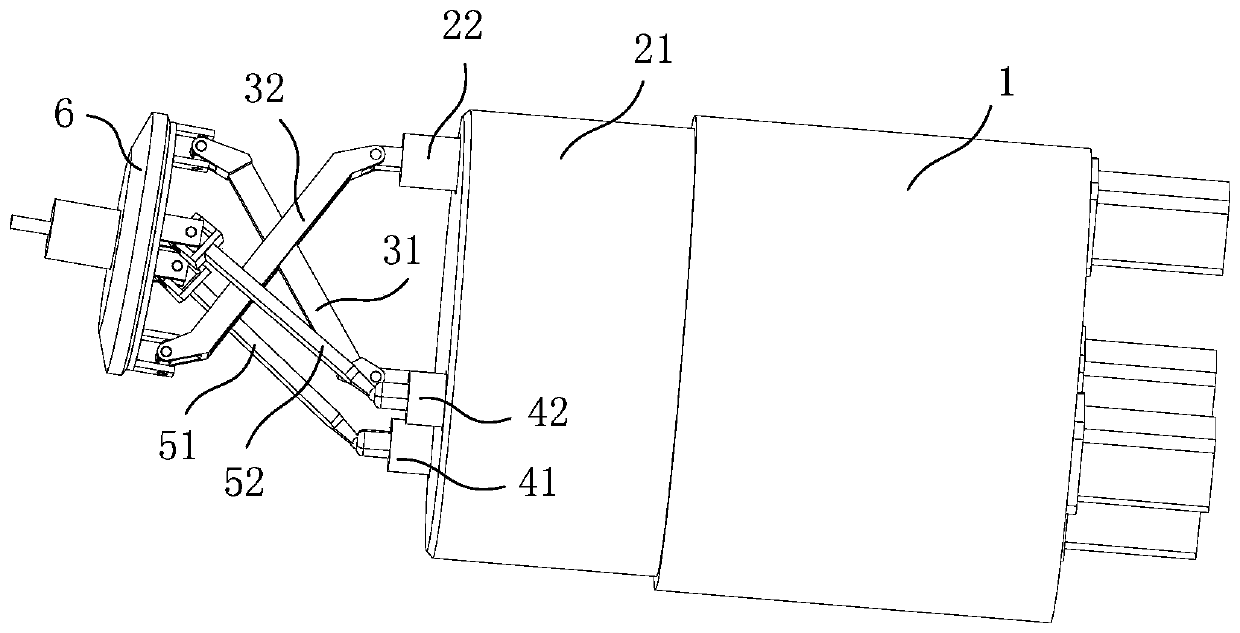

[0037] exist figure 2 In the schematic diagram of the two-rotation and two-movement parallel processing swing head mechanism shown, four sets of linear drive modules 21, 22, 41, 42 are fixed on the fixed cylinder 1, wherein the second linear drive module 21 and the first linear drive module 22 are fixed In the left and right symmetry plane of the fixed cylinder 1, two sets of third linear drive modules 41 and 42 are symmetrically fixed on both sides of the left and right symmetry plane, and the two sets of third linear drive modules 41 and 42 are arranged close to the second linear drive module 21, and the first The linear drive module 22 and two groups of third linear drive modules 41, 42 pass through the moving end of the second linear drive module 21, and the first ends of the two first connecting rods 31, 32 are respectively connected to the second linear drive module through a rotating hinge. The module 21 is connected to the moving end of the first linear drive module 2...

Embodiment 2

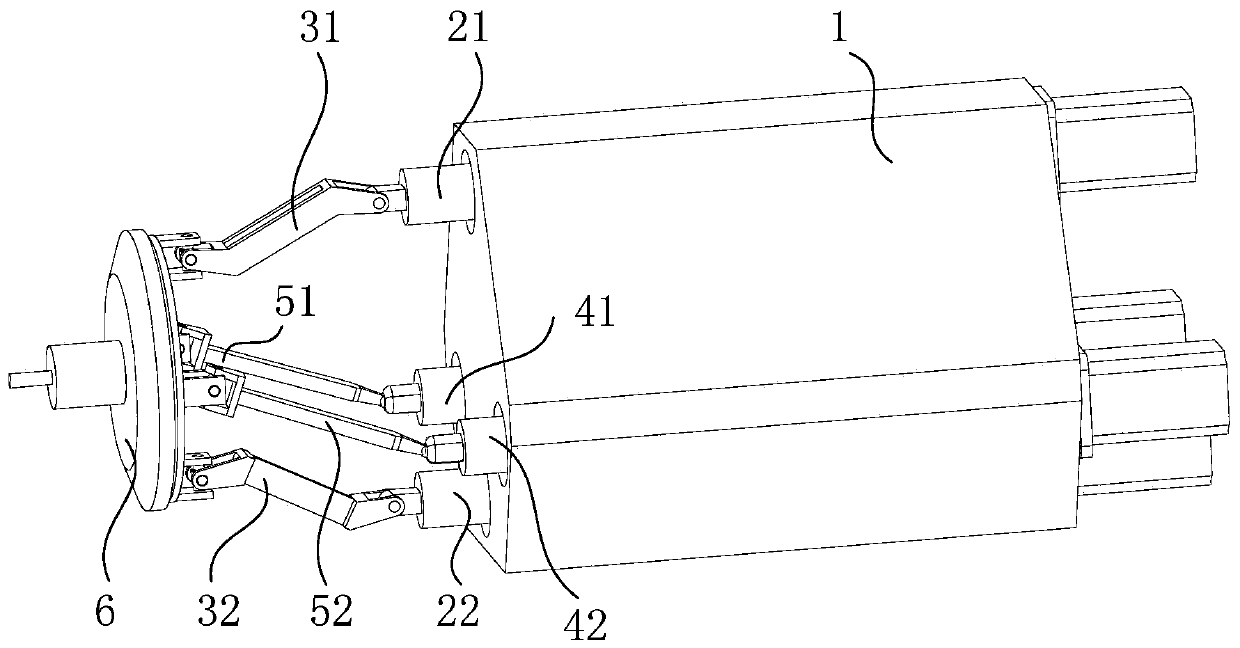

[0039] image 3It is a structural schematic diagram of the two-rotation and two-movement parallel processing swing head mechanism according to the second embodiment of the present invention, wherein four sets of linear drive modules 21, 22, 41, 42 are fixed on the fixed cylinder 1, and the first linear drive module 22 and the second linear drive module 21' are fixed in the left and right symmetrical planes of the fixed cylinder 1, and two sets of third linear drive modules 41, 42 are symmetrically fixed on both sides of the left and right symmetrical planes of the fixed cylinder 1; the two first connecting rods 31, 32 The first ends are respectively connected to the moving ends of the two groups of first linear drive modules through rotating hinges, and the first ends of the two second connecting rods 51, 52 are respectively connected to the two groups of third linear drive modules 41, 42 through spherical hinges. The moving end is connected; the second end of each first conne...

Embodiment 3

[0043] exist Figure 4 In the shown schematic diagram of the two-rotation and two-movement parallel processing swing head mechanism according to the third embodiment of the present invention, four sets of linear drive modules 21, 22, 41, 42 are fixed on the fixed cylinder 1, and the first linear drive module 21 and the second linear drive module 22 are fixed in the left and right symmetrical planes of the fixed cylinder 1, and two groups of third linear drive modules 41, 42 are symmetrically fixed on both sides of the left and right symmetrical planes of the fixed cylinder; the first of the two first connecting rods 31, 32 The two ends are respectively connected to the moving ends of the first linear drive module 22 and the second linear drive module 21 through rotating hinges, and the first ends of the two second connecting rods 51, 52 are respectively connected to the two groups of third linear drive modules through ball joints. The moving ends of 41 and 42 are connected; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com