Multi-line trl calibration method and terminal equipment

A calibration method and technology of calibration parts, which are applied in the direction of instruments, measuring devices, and measuring electrical variables, etc., and can solve the problems of low measurement accuracy of S parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

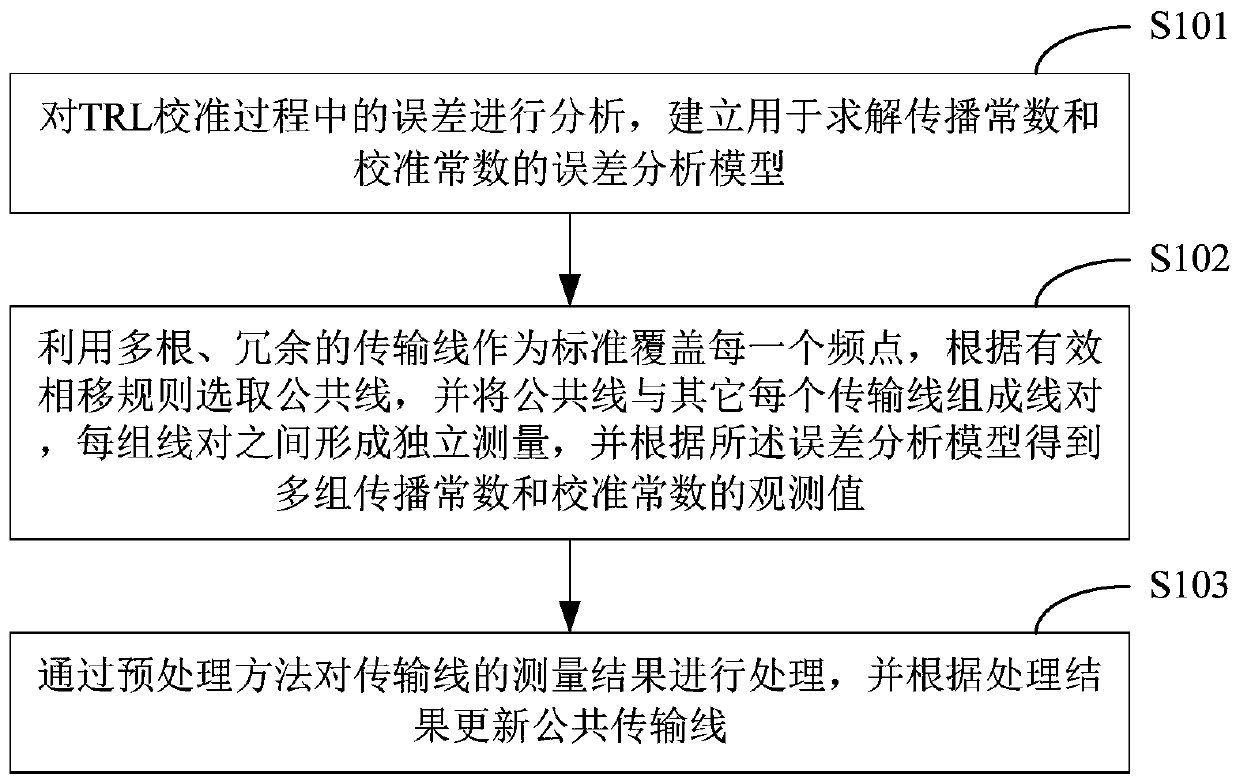

[0172] figure 1 The implementation flow of the multi-line TRL calibration method provided by Embodiment 1 of the present invention is shown, and the details are as follows:

[0173] Step S101 , analyzing the errors in the TRL calibration process, and establishing an error analysis model for solving propagation constants and calibration constants.

[0174] In this step, the error in the TRL calibration process is analyzed, and the process of establishing an error analysis model for solving the propagation constant and the calibration constant is:

[0175] The concatenated transfer matrix M of the i-th calibration piece measured by Yaneti i for

[0176]

[0177] Among them, T i is the actual transmission matrix of the calibration part i, X and Y are the transmission matrix of the error network to be obtained, that is, the calibration constant; Indicates that the direction of signal transmission is opposite to that of Y. For example, if Y represents the transfer matrix...

Embodiment 2

[0270] Corresponding to the multi-line TRL calibration method described in the above embodiment, Figure 7 A schematic diagram of the operating environment of the multi-line TRL calibration program provided by the embodiment of the present invention is shown. For ease of description, only the parts related to this embodiment are shown.

[0271] In this embodiment, the multi-line TRL calibration program 200 is installed and runs in the terminal device 20 . The terminal device 20 may include, but not limited to, a memory 201 and a processor 202 . Figure 7 Only terminal device 20 is shown with components 201-202, but it is to be understood that implementation of all of the illustrated components is not required and that more or fewer components may instead be implemented.

[0272] The storage 201 may be an internal storage unit of the terminal device 20 in some embodiments, for example, a hard disk or a memory of the terminal device 20 . The memory 201 may also be an external...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com