Automatic lifting and locking device and method for offshore floating platform

A floating platform, automatic lifting technology, applied in floating buildings, water conservancy projects, artificial islands, etc., can solve the danger of workers and equipment, failure of lifting and locking devices, increase in system complexity, energy consumption failure rate and construction, Maintenance costs and other issues, to achieve the effect of reducing construction and operating costs, no code errors and human errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

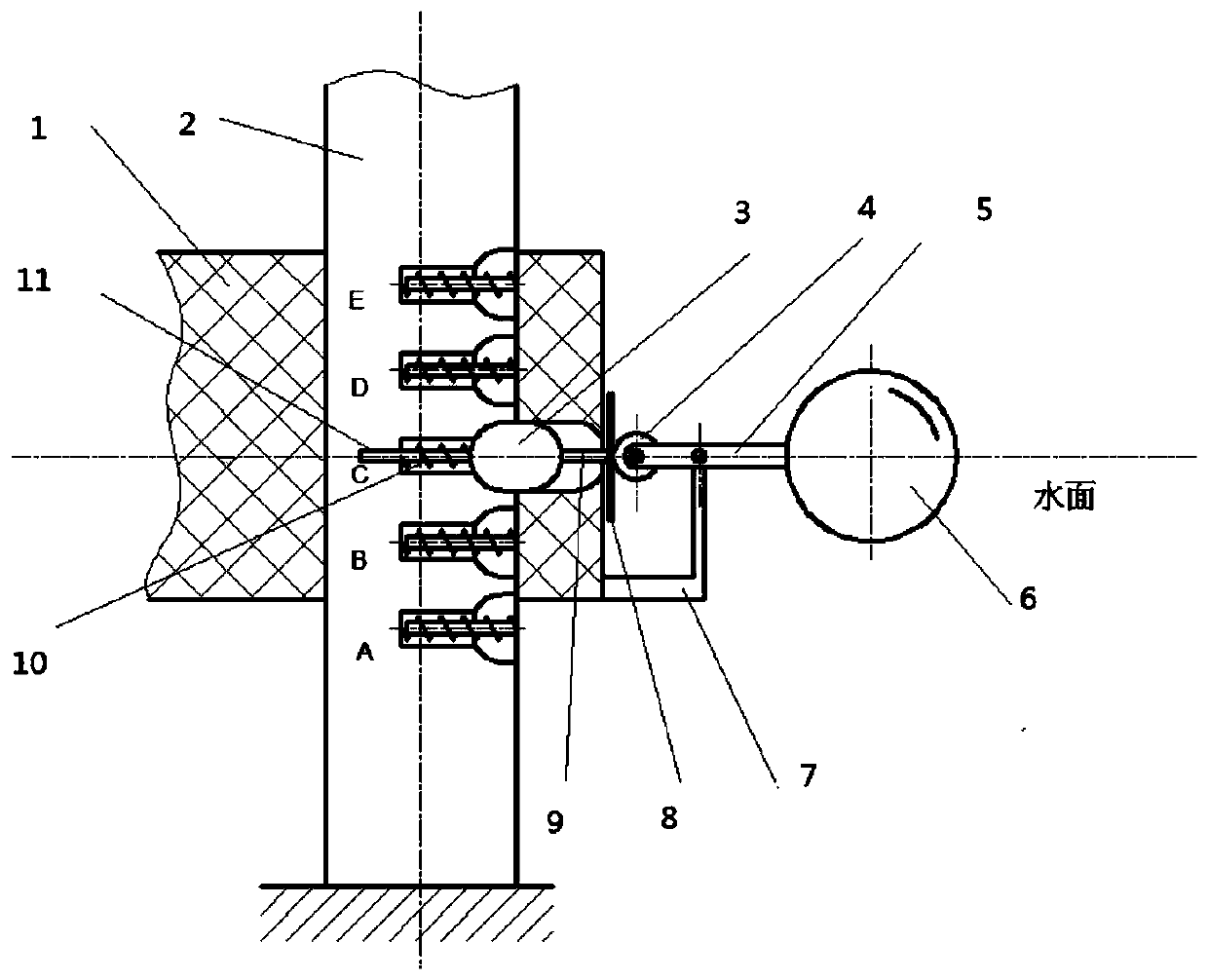

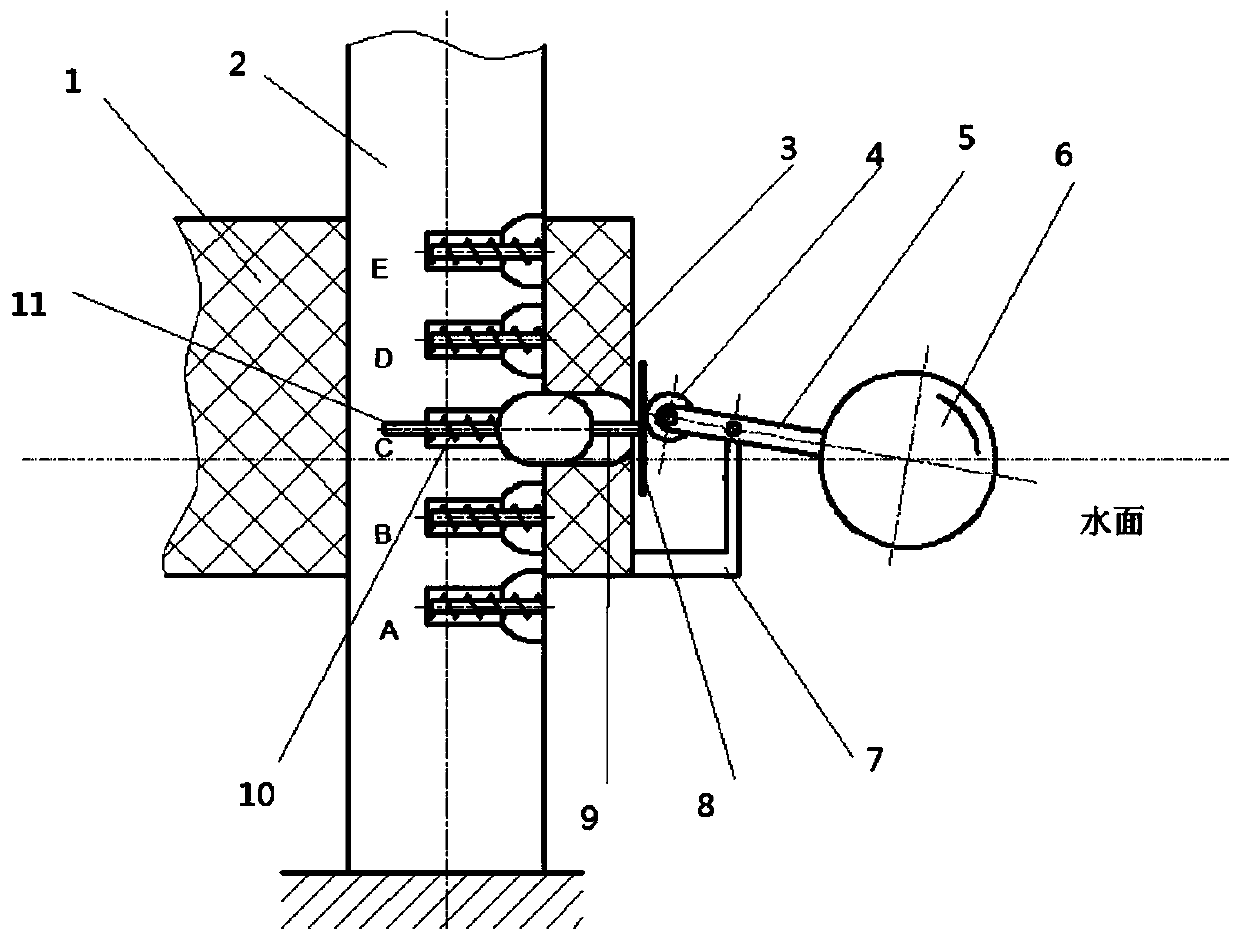

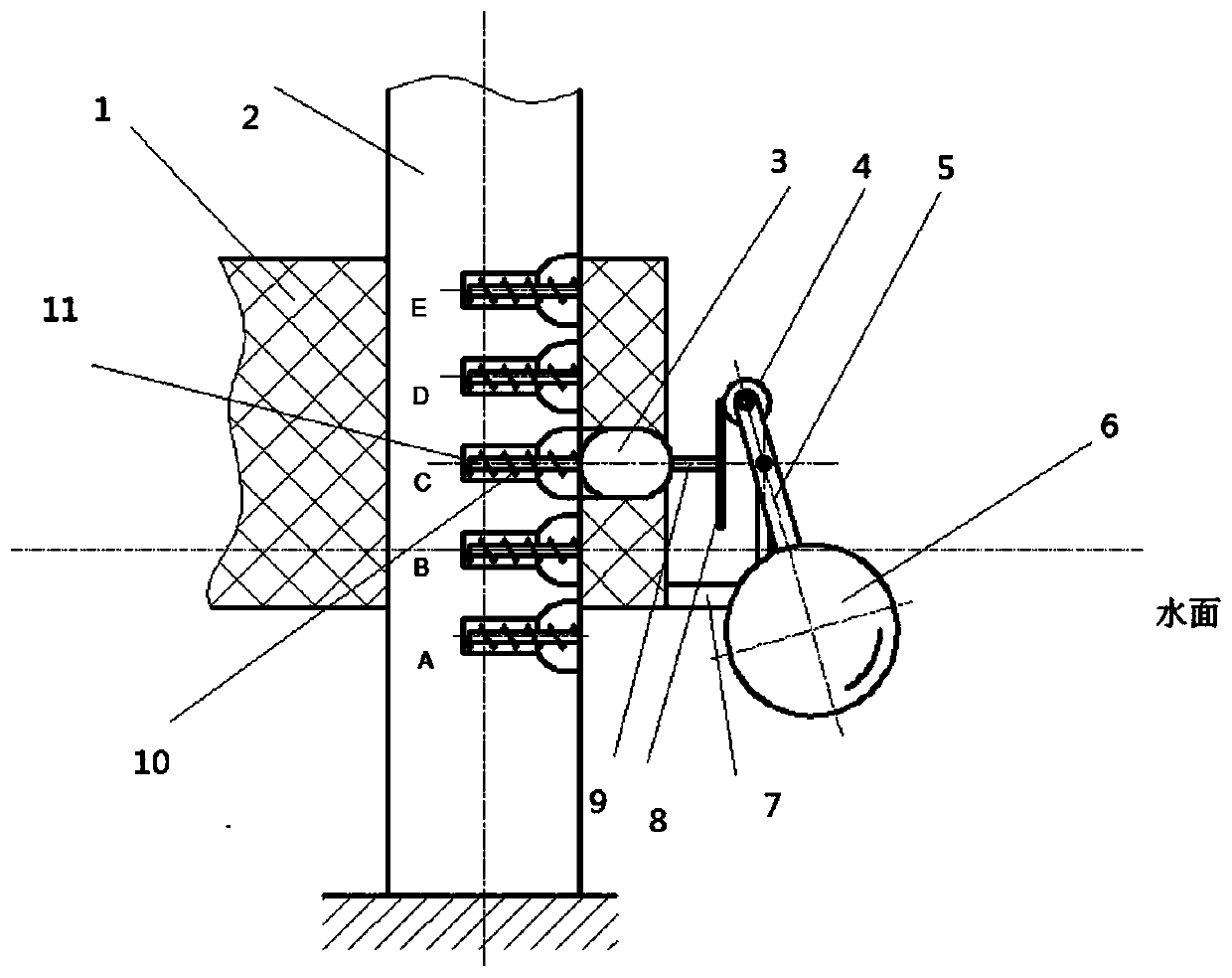

[0031]The present invention is mainly aimed at those working floating platforms that are operated on the sea surface, and need to rely on support columns anchored on the seabed to bear natural force and engineering force, keep the working position unchanged, and rise and fall with the tide. The present invention designs and installs a mechanical automatic unlocking and locking mechanism between the floating platform and the support column, which consists of sliding pins, push rods, push plates, floating balls, swing rods, rollers, connecting frames, compression springs and Rod composition. The sliding pin is located in the horizontal hole of the floating platform and the supporting column, and can move horizontally. When the floating platform and the floating ball are in balance, part of the sliding pin is located in the horizontal hole of the floating platform, and the other part is located in the horizontal hole of the supporting column. The floating platform is in the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com