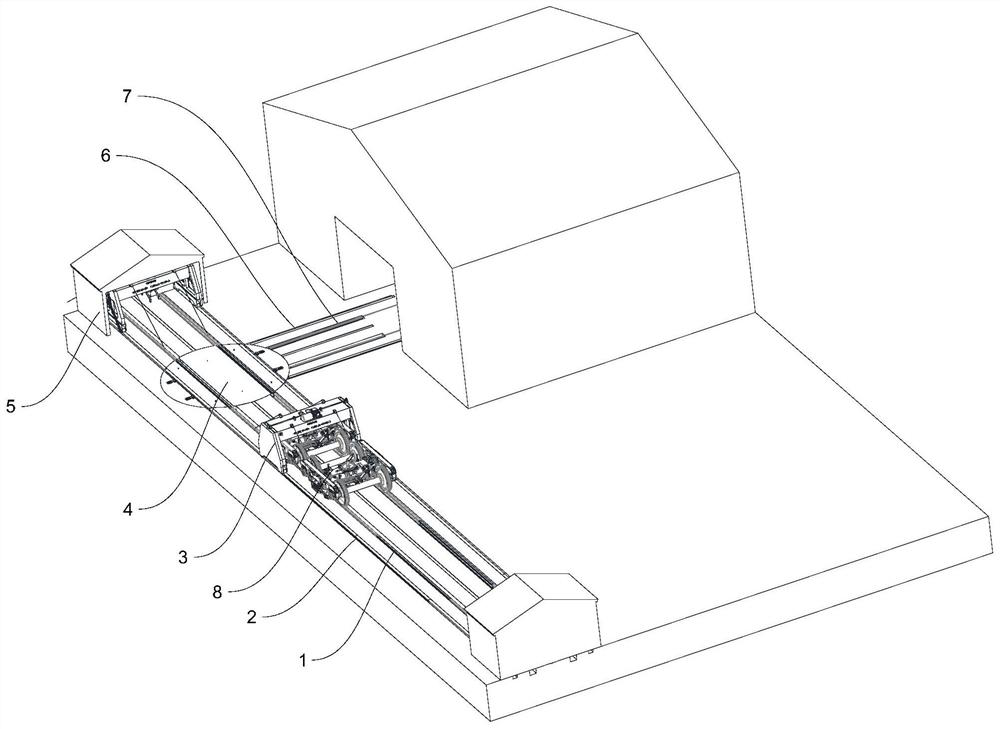

A rail vehicle bogie transfer conveying device

A rail vehicle and conveying device technology, applied in the field of bogie automatic conveying assembly, can solve problems such as high work intensity, heavy bogie weight, troublesome alignment, etc., and achieve the goal of improving transfer and conveying efficiency, reducing labor intensity, and stabilizing the transmission process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

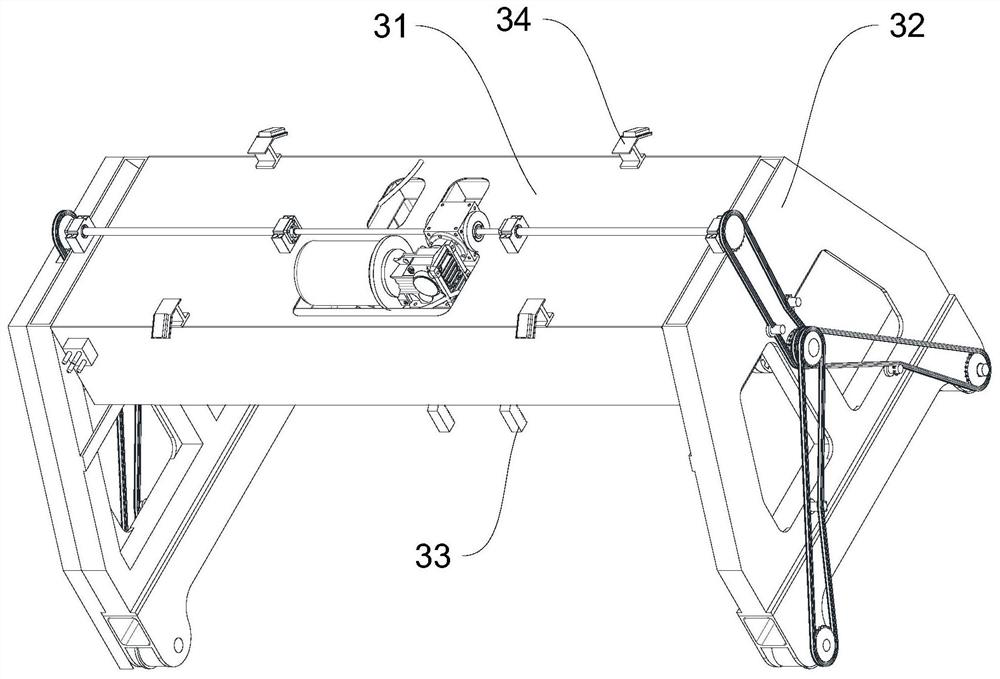

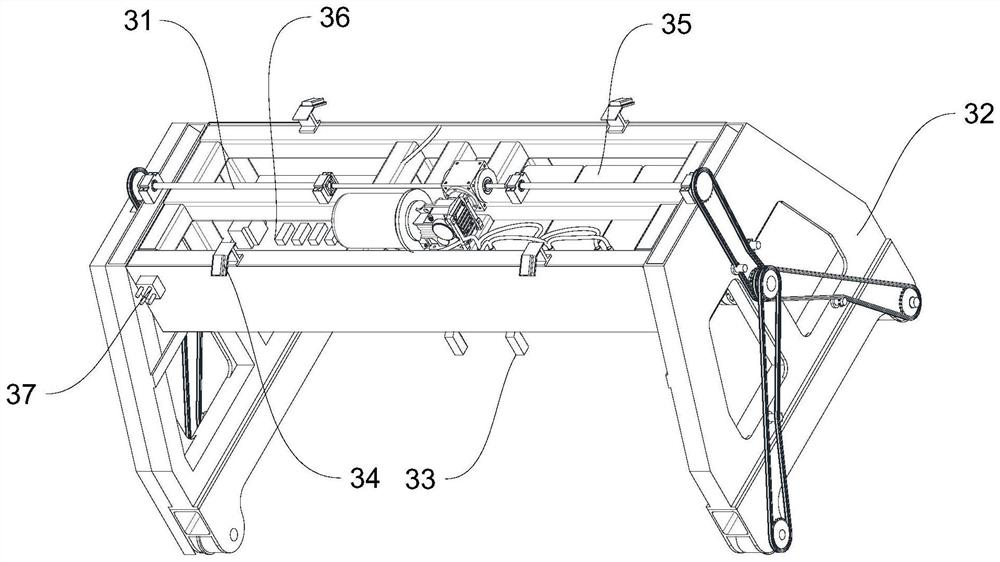

[0059] Method 1: see Figure 8 and Figure 9 , the coupling mechanism 33 includes a top plate 3301a fixedly connected to the beam 3101, at least one slide rail 3302a is installed on the side of the top plate 3301a away from the beam 3101, two sliding seats are installed on the slide rail 3302a, and cross rails 3303a are installed on the two sliding seats 3303a. The arm 3304a and the top plate 3301a are equipped with a grasping driving mechanism 3305a for driving the relative movement of the two sliding seats 3303a. The cross arm 3304a is mainly used for clamping the train bogie 8, so that the traction device 3 is fixedly connected with the train bogie 8, and the clamping method can be scissor clamping or direct close clamping, see Figure 8 , The clamping method in this embodiment is scissor clamping. The grasping driving mechanism 3305a can be realized by linear motion mechanisms such as two-way hydraulic cylinders, motor racks and pinions, motor ball screws, etc. These are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com