A kind of antiferroelectric lead-free ceramics and its preparation method and application

An electric lead-free ceramic and antiferroelectric technology, applied in the field of antiferroelectric ceramic materials, can solve the problems of environmental and human hazards, inability to provide dielectric properties at room temperature, lead content, etc., and achieve excellent energy storage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides the preparation method of the antiferroelectric lead-free ceramics described in the above technical solution, comprising the following steps:

[0032] will Cs 2 CO 3 with Nb 2 O 5 The first ball milling, the first high temperature heat preservation, the grinding and the second high temperature heat preservation are carried out in sequence to obtain Cs 2 Nb 4 O 11 powder;

[0033] will Bi 2 O 3 , Na 2 CO 3 , BaCO 3 , TiO 2 and the Cs 2 Nb 4 O 11 The powder is sequentially subjected to second ball milling and calcination to obtain BNT-BT-CN powder;

[0034] Mixing and granulating the BNT-BT-CN powder with polyvinyl alcohol and pressing to obtain a blank;

[0035] The blanks are sintered to obtain antiferroelectric lead-free ceramics.

[0036] In the present invention, unless otherwise specified, all preparation raw materials are commercially available commodities well known to those skilled in the art.

[0037] The pre...

Embodiment 1

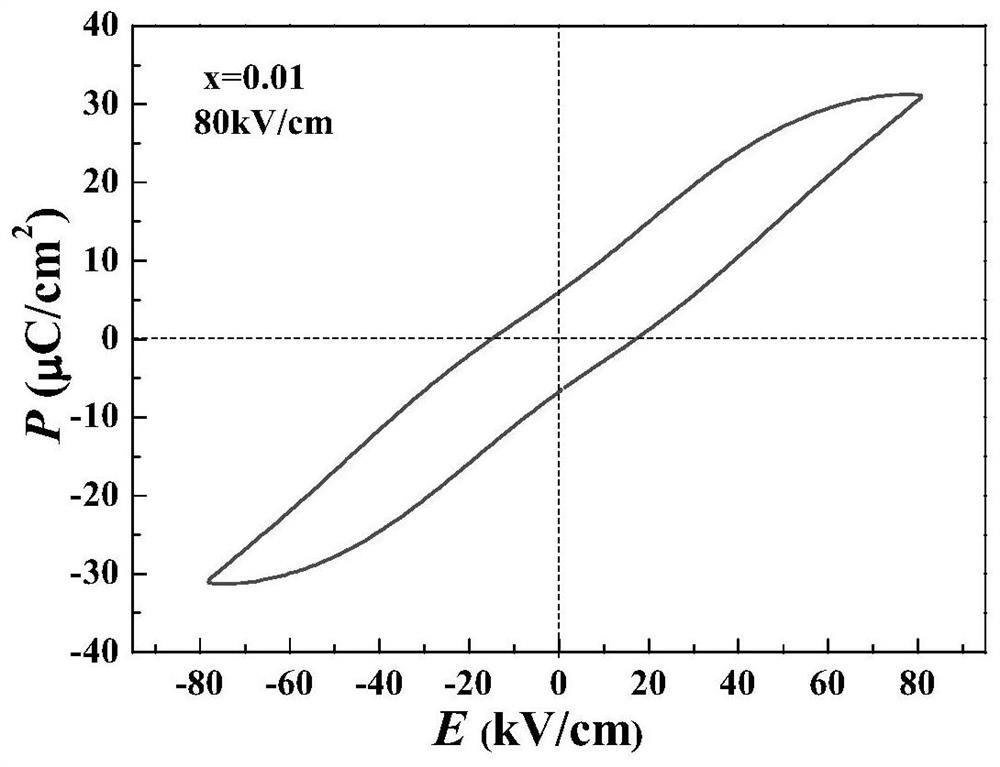

[0054] (1-x)(0.94(Bi 0.5 Na 0.5 )TiO 3 -0.06BaTiO 3 )-xCs 2 Nb 4 O 11 where x=0.01.

[0055] The preparation method is as follows:

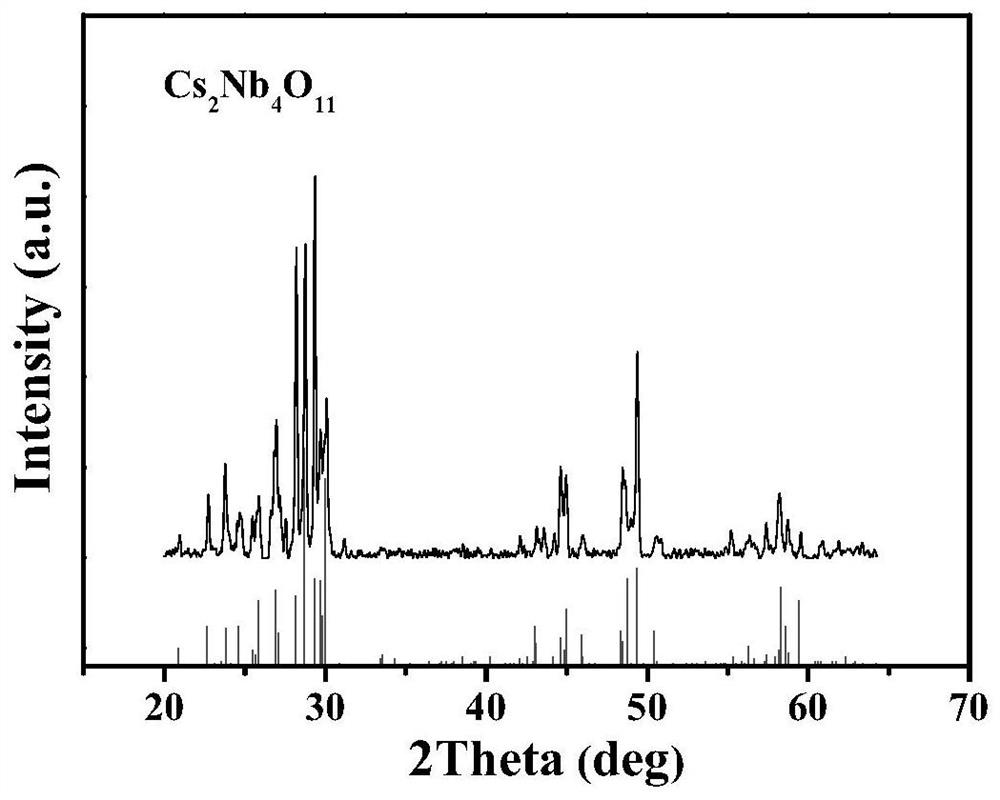

[0056] The electronic grade raw material Cs 2 CO 3 with Nb 2 O 5 According to the atomic ratio in the composition of the antiferroelectric lead-free ceramic element, a total of 2 mol was weighed, and the zirconium ball was used for ball milling in a ball milling jar with absolute ethanol as the medium. for 18h; dry the ball-milled sample and place it in a crucible, then put it in a muffle furnace for 2 hours at 600 °C, then take it out for grinding to make it fully mixed, and then place the ground material in the muffle furnace Incubate at 850 °C for 2 h to obtain Cs 2 Nb 4 O 11 powder. The synthesized Cs 2 Nb 4 O 11 After drying, the samples were tested by XRD. The test results are shown in figure 1 . Depend on figure 1 It can be seen that the present invention successfully obtained the element composition of Cs 2 Nb 4 O ...

Embodiment 2

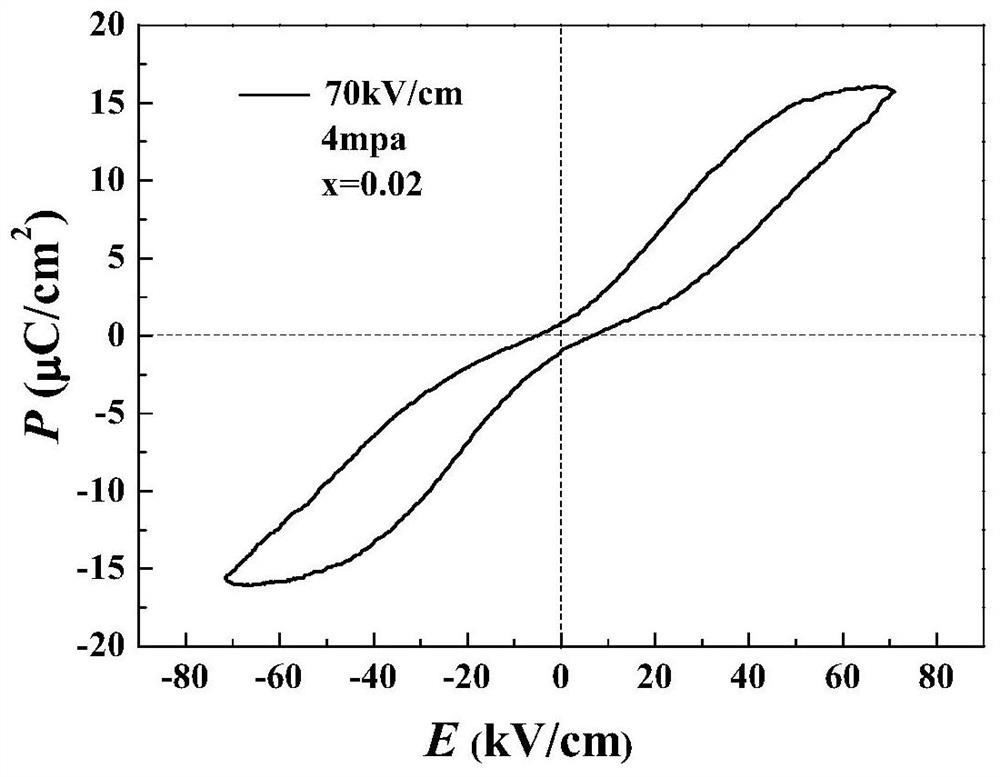

[0063] (1-x)(0.94(Bi 0.5 Na 0.5 )TiO 3 -0.06BaTiO 3 )-xCs 2 Nb 4 O 11 where x=0.02.

[0064] The preparation method is as follows:

[0065] The sintering is divided into the first sintering and the second sintering in sequence: the temperature of the first sintering is 1200°C and the time is 5min; the temperature of the second sintering is 1150°C and the time is 6h;

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com