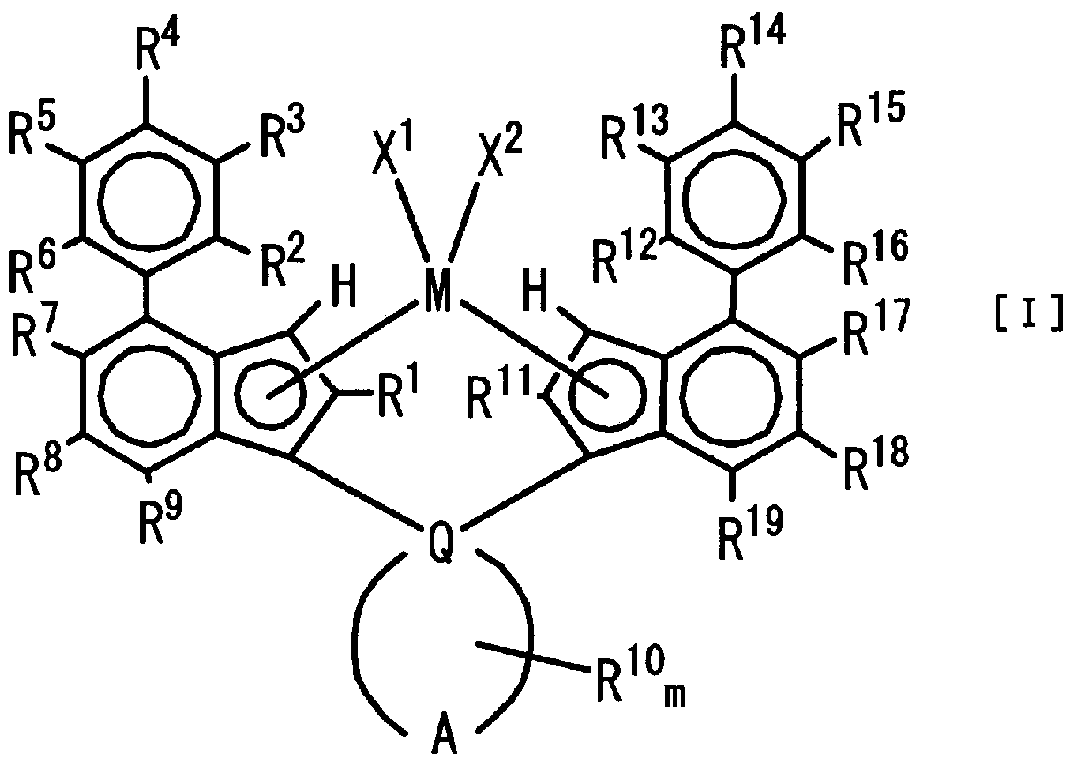

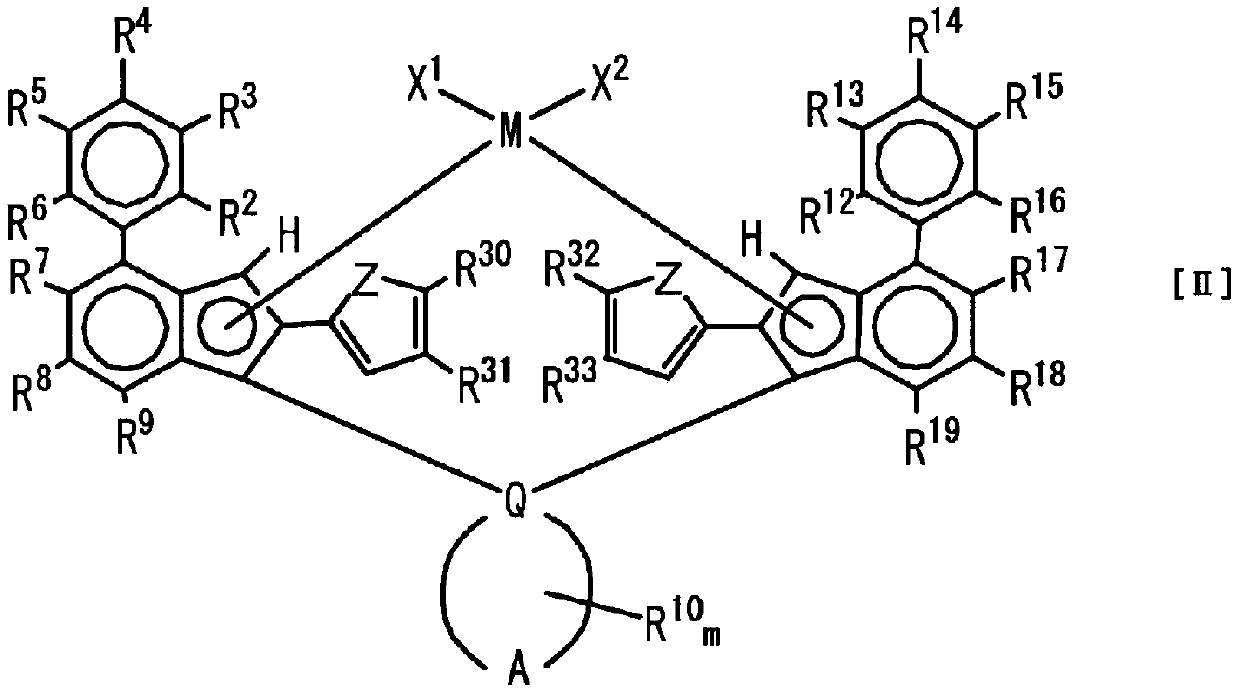

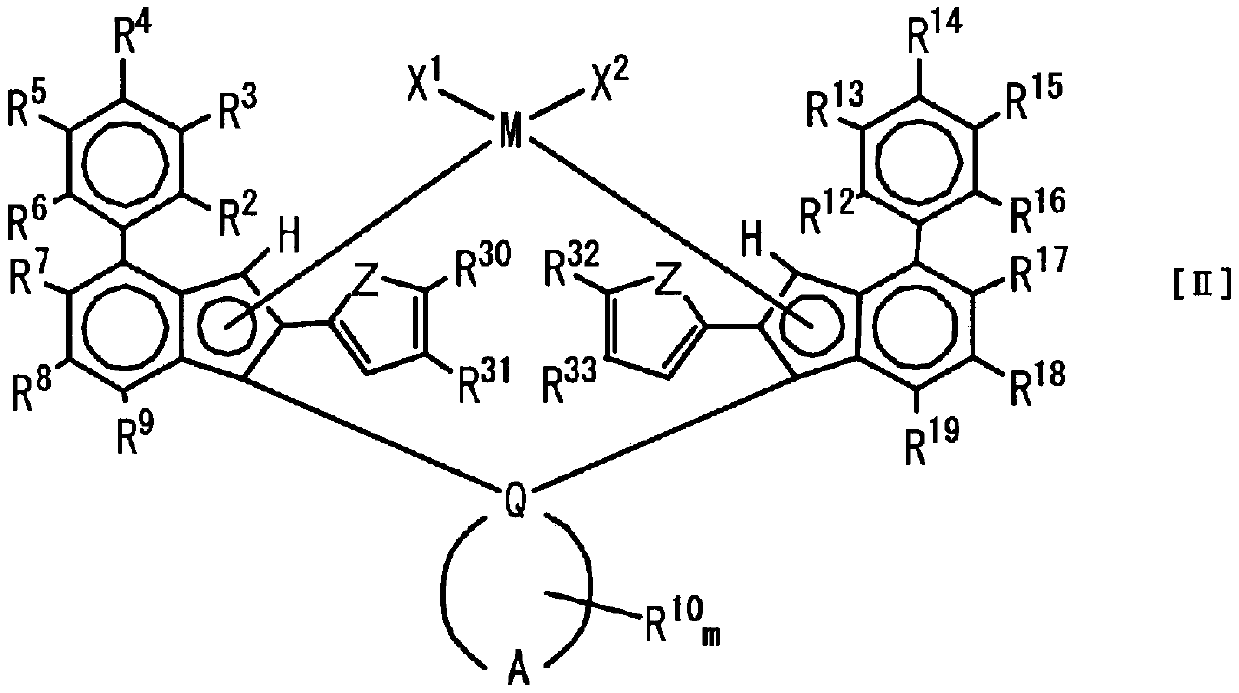

Metallocene complex and method for manufacturing olefin polymer

A metallocene complex and olefin polymerization technology, applied in metallocene, chemical instruments and methods, organic chemistry, etc., can solve the problems of not having enough high performance, and achieve high intake efficiency, excellent flexibility or impact resistance , the effect of high intake efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0231] (3) Preparation method of catalyst

[0232] In the method for producing a catalyst for olefin polymerization according to the present invention, the method of contacting component (A), component (B) and component (C) is not particularly limited, but includes, for example, the following methods:

[0233] (i) a method of contacting component (A) with component (B), and then adding component (C);

[0234] (ii) a method of contacting component (A) with component (C) and then adding component (B);

[0235] (iii) a method of contacting component (B) with component (C), and then adding component (A);

[0236] (iv) A method of simultaneously bringing the components (A), (B) and (C) into contact.

[0237] Furthermore, each component may be used as a mixture of different kinds of components, or may be contacted individually in a different order. This contacting can take place not only during the catalyst preparation but also during the prepolymerization of the olefin or during...

Embodiment 1

[0339] Metallocene Complex A: Silacyclobutylenebis[2-(5-methyl-2-furyl)-4-phenyl-1,5,6,7-tetrahydro-s-dicyclopentadiene Synthesis of alkenen-1-yl]zirconium dichloride

[0340] (1-1) Synthesis of 4-bromo-1,2,3,5-tetrahydro-s-dicyclopentadiene (4-bromo-1,2,3,5-tetrahydro-s-indacene)

[0341] 4-Bromo-3,5,6,7-tetrahydro-2H-s-benzobisinden-1-one (4-Bromo-3,5,6,7-tetrahydro-2H-s-indacen-1 -one) (45 g) was added to a suspension of aluminum chloride (81 g) and chloroform (300 mL). After stirring at room temperature for 1 hour, a solution of bromine (13 mL) in chloroform (40 mL) was added dropwise under cooling in an ice bath, and reacted at room temperature day and night. After the reaction was completed, the reaction solution was poured into 1N hydrochloric acid-ice water, followed by stirring. The organic layer was separated, washed with 1N hydrochloric acid, water and saturated brine, and dried over magnesium sulfate. The solvent was removed by distillation under reduced pressu...

Embodiment 2

[0375] Metallocene Complex B: Silacyclopentylenebis[2-(5-methyl-2-furyl)-4-phenyl-1,5,6,7-tetrahydro-s-dicyclopentadiene Synthesis of alkenen-1-yl]zirconium dichloride (metallocene complex B)

[0376] (2-1) 1,1-bis[2-(5-methyl-2-furyl)-4-phenyl-1,5,6,7-tetrahydro-s-dicyclopentadieneacene Synthesis of -1-yl]silacyclobutane

[0377] 4-Phenyl-6-(5-methyl-2-furyl)-1,2,3,5-tetrahydro-s-dicyclopentadieneacene (5.0g, 16.0mmol) was dissolved in tetrahydrofuran (75mL), and added dropwise n-butyllithium in n-hexane (1.58M, 11mL) at -78°C. After stirring for 3 hours while gradually raising the temperature to room temperature, N-methylimidazole (0.06 mL) and 1,1-dichlorosilacyclobutane (1.1 mL, 8.4 mmol) were added dropwise at -78°C, and The resulting solution was stirred for 2.5 hours while gradually raising the temperature to room temperature. The organic layer was separated by adding water, dried over magnesium sulfate, and after distilling off the solvent under reduced pressure, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com