High foaming scratch-resistant polypropylene foaming material and preparation method thereof

A foamed material, polypropylene technology, applied in the field of high-expansion, scratch-resistant polypropylene foamed material and its preparation, can solve the problems of easy scratching and cracking, poor surface effect, affecting appearance and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

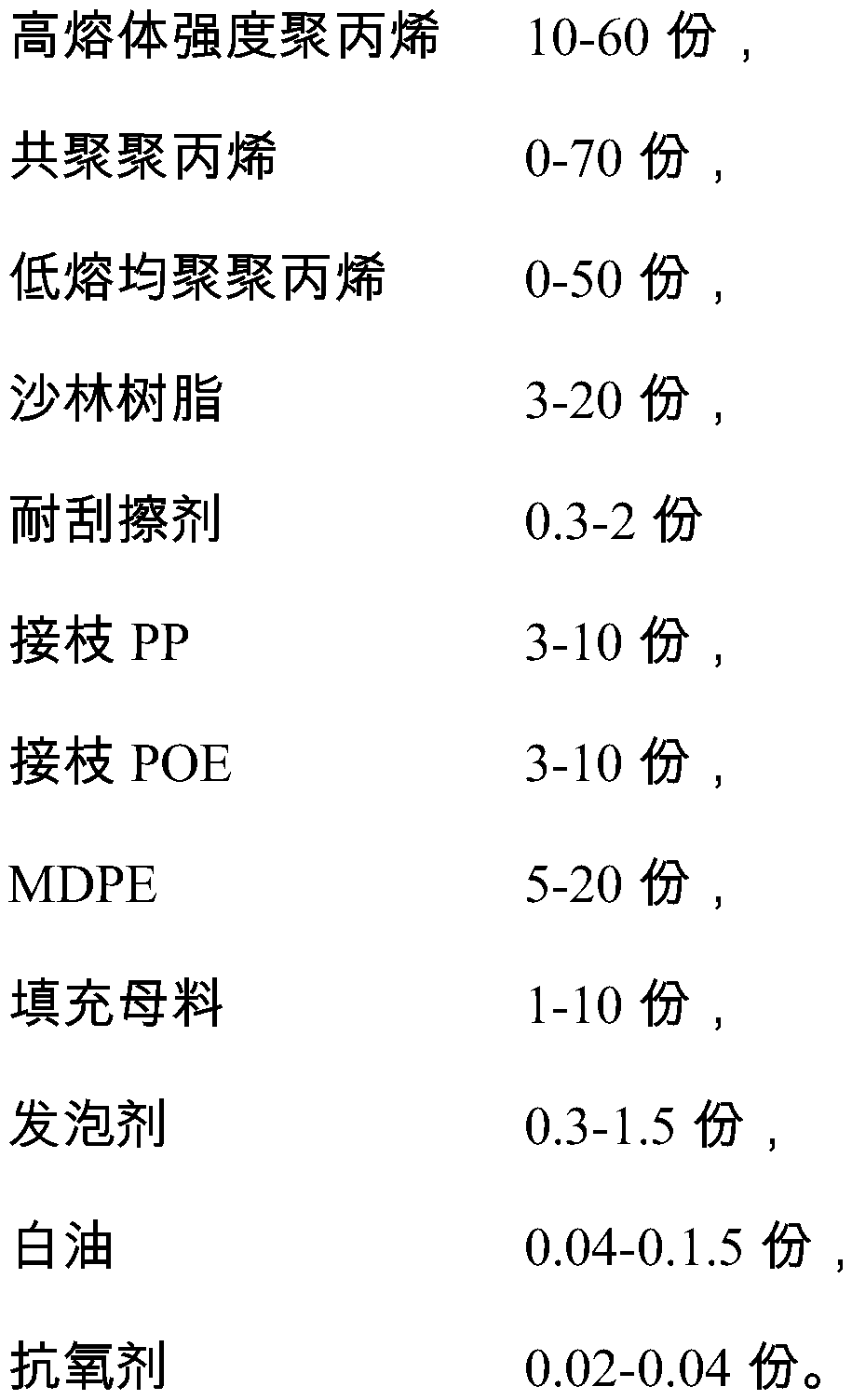

[0025] A high-expansion and scratch-resistant polypropylene foam material, the materials used in the production of the high-expansion and scratch-resistant polypropylene foam material include the following components and requirements

[0026]

[0027]

[0028] In this proportion, the high-melt-strength polypropylene is mainly used as a foaming material; the selection of sarin resin can improve the melt strength of the material and at the same time improve the wear resistance of the material and the comfort of the surface; the use of the scratch-resistant agent, Improve the scratch resistance of the material; the use of grafted POE can improve the compatibility of multi-phase components, and effectively improve the stress whitening phenomenon of multiple component systems after scratching; the use of grafted PP improves the multi-phase Compatibility of components; the use of MDPE improves the wear resistance of the material while improving the melt strength of the material...

Embodiment 2

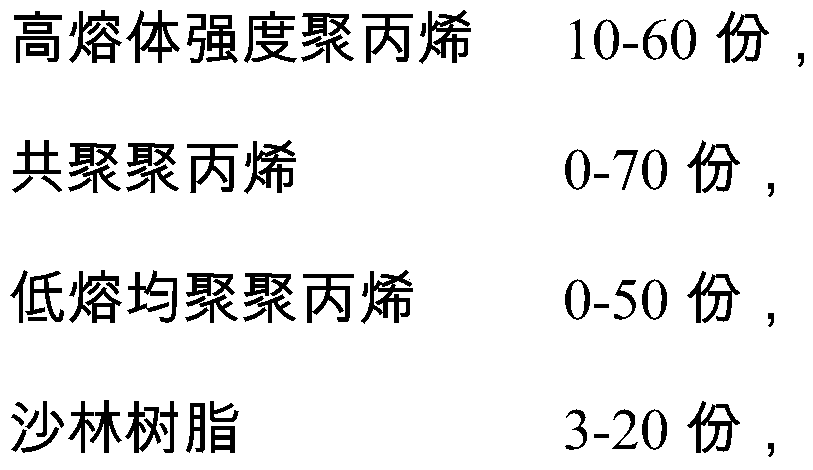

[0036] A high-expansion and scratch-resistant polypropylene foam material, the materials used in the production of the high-expansion and scratch-resistant polypropylene foam material include the following components and requirements

[0037]

[0038]

[0039] In this proportion, the high-melt-strength polypropylene is mainly used as a foaming material; the selection of sarin resin can improve the melt strength of the material and at the same time improve the wear resistance of the material and the comfort of the surface; the use of the scratch-resistant agent, Improve the scratch resistance of the material; the use of grafted POE can improve the compatibility of multi-phase components, and effectively improve the stress whitening phenomenon of multiple component systems after scratching; the use of grafted PP improves the multi-phase Compatibility of components; the use of MDPE improves the wear resistance of the material while improving the melt strength of the material...

Embodiment 3

[0047] A high-expansion and scratch-resistant polypropylene foam material, the materials used in the production of the high-expansion and scratch-resistant polypropylene foam material include the following components and requirements

[0048]

[0049] In this proportion, the high-melt-strength polypropylene is mainly used as a foaming material; the selection of sarin resin can improve the melt strength of the material and at the same time improve the wear resistance of the material and the comfort of the surface; the use of the scratch-resistant agent, Improve the scratch resistance of the material; the use of grafted POE can improve the compatibility of multi-phase components, and effectively improve the stress whitening phenomenon of multiple component systems after scratching; the use of grafted PP improves the multi-phase Compatibility of components; the use of MDPE improves the wear resistance of the material while improving the melt strength of the material; the use of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com