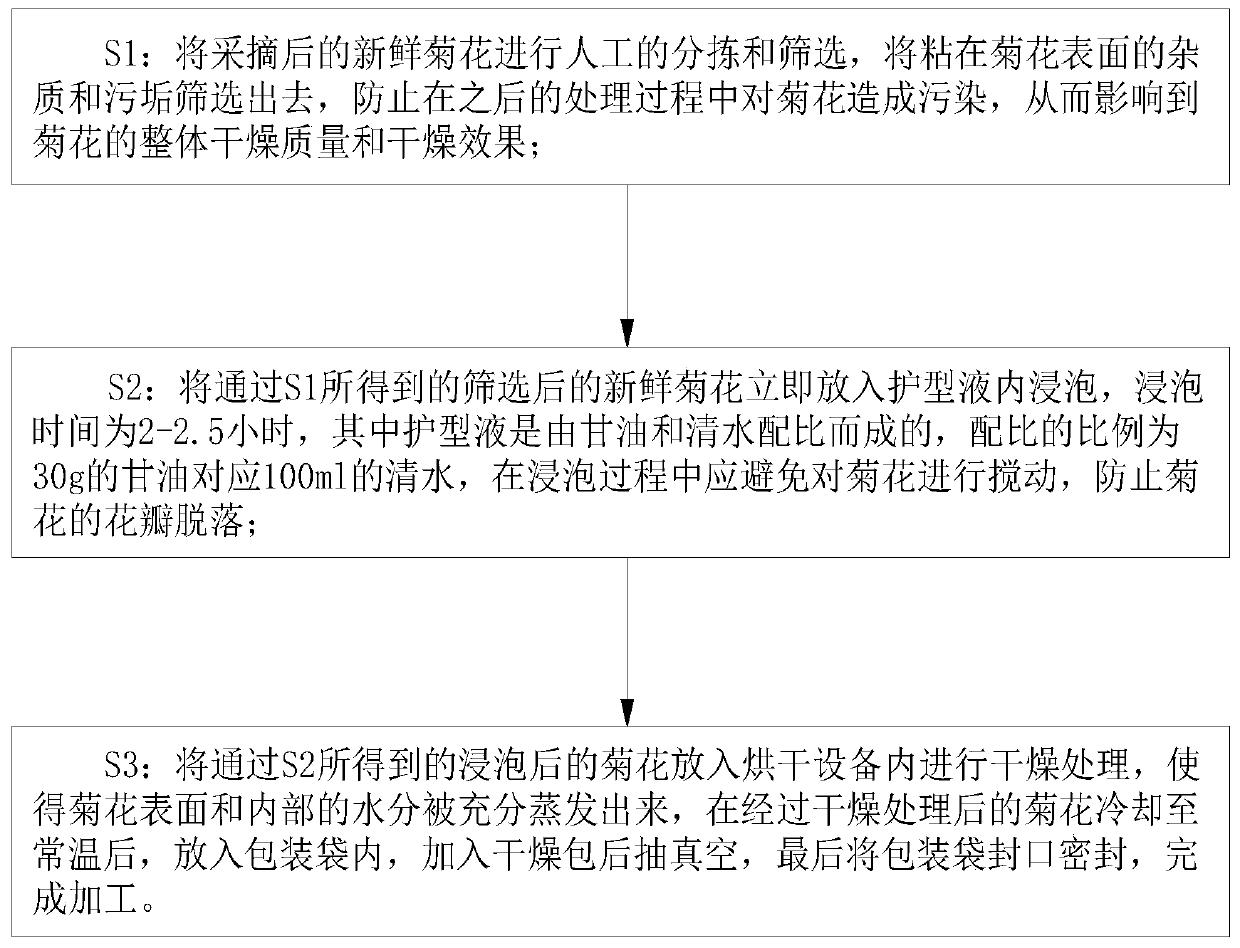

Low-temperature hot air circulation vacuum combined drying method for chrysanthemum

A technology of hot air circulation and combined drying, which is applied in the direction of drying solid materials without heating, drying solid materials, drying gas layout, etc., can solve problems such as easy damage, and achieve the effect of reducing nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

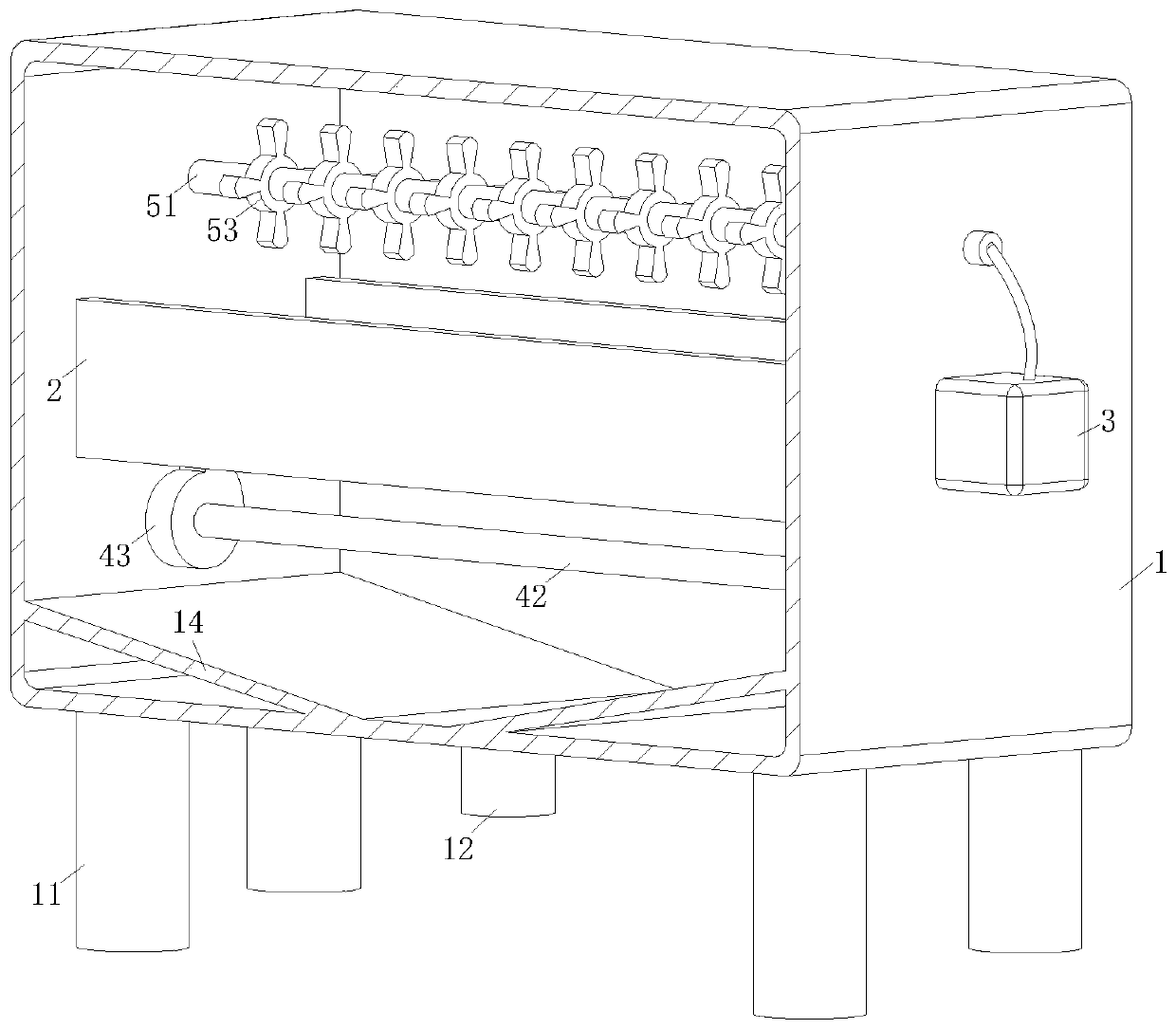

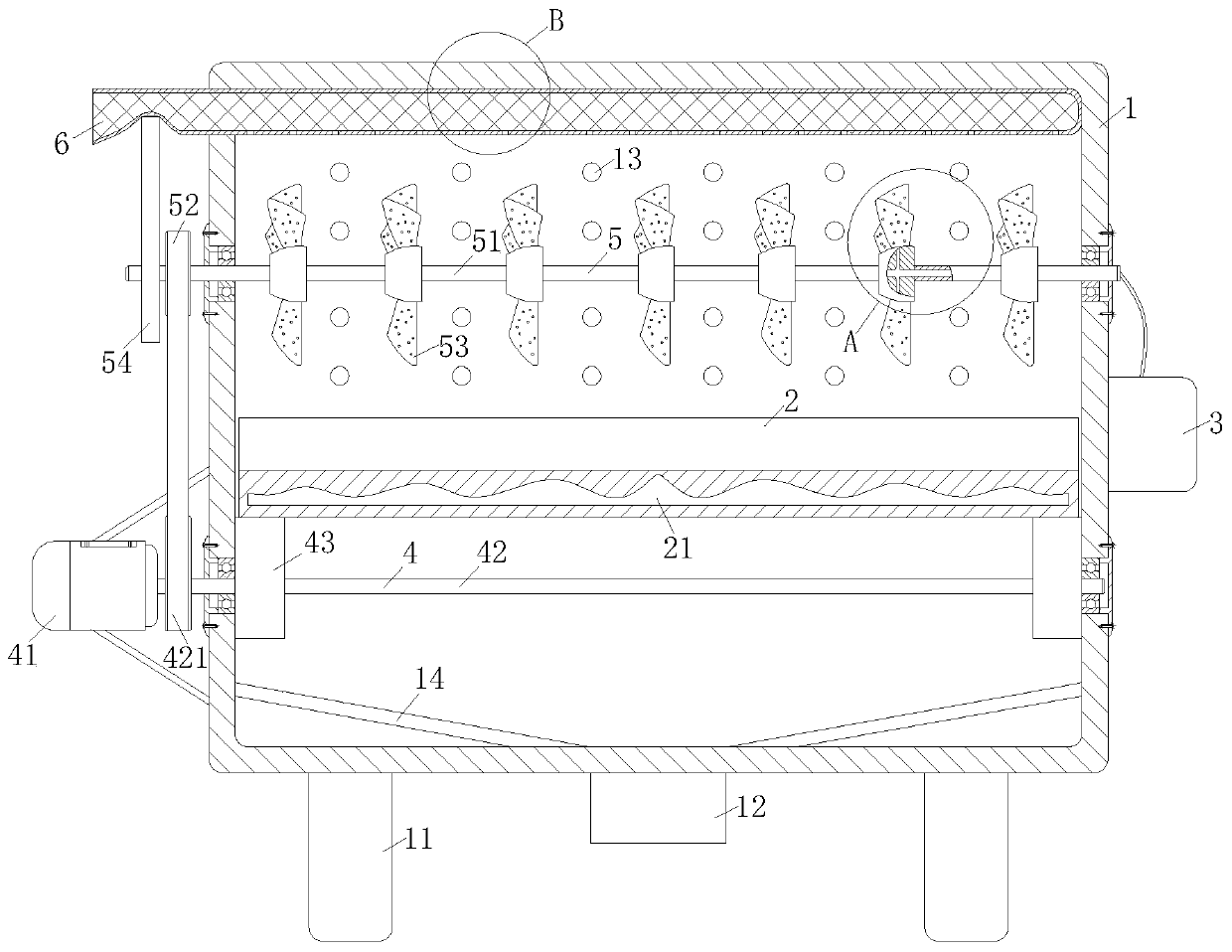

[0032] As an embodiment of the present invention, the output end of the motor 41 is located outside the housing 1 and is provided with a first wheel 421; the rotating unit 5 includes a second rotating shaft 51, a second wheel 52 and a fan 53; The second rotating shaft 51 runs through the housing 1 transversely and is located at the upper end of the U-shaped plate 2, and the second rotating shaft 51 is provided with a cavity 511; the cavity 511 is connected to the outlet of the hot blast stove 3; the second wheel 52 is set The position where the second rotating shaft 51 is located outside the casing 1, and the second wheel 52 and the first wheel 421 are connected by a transmission belt; No. 2 hot air outlet 531 is provided, and the hot air outlet communicates with the cavity 511; the chrysanthemum on the U-shaped plate 2 is dried by the cooperation of the first wheel 421, the second rotating shaft 51, the second wheel 52 and the fan 53; When the controller controls the motor 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com