Pressure loading device for high-pressure neutron diffraction

A loading device and neutron technology, applied in the direction of applying stable tension/pressure to test material strength, using wave/particle radiation for material analysis, measuring devices, etc., can solve problems such as anvil damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

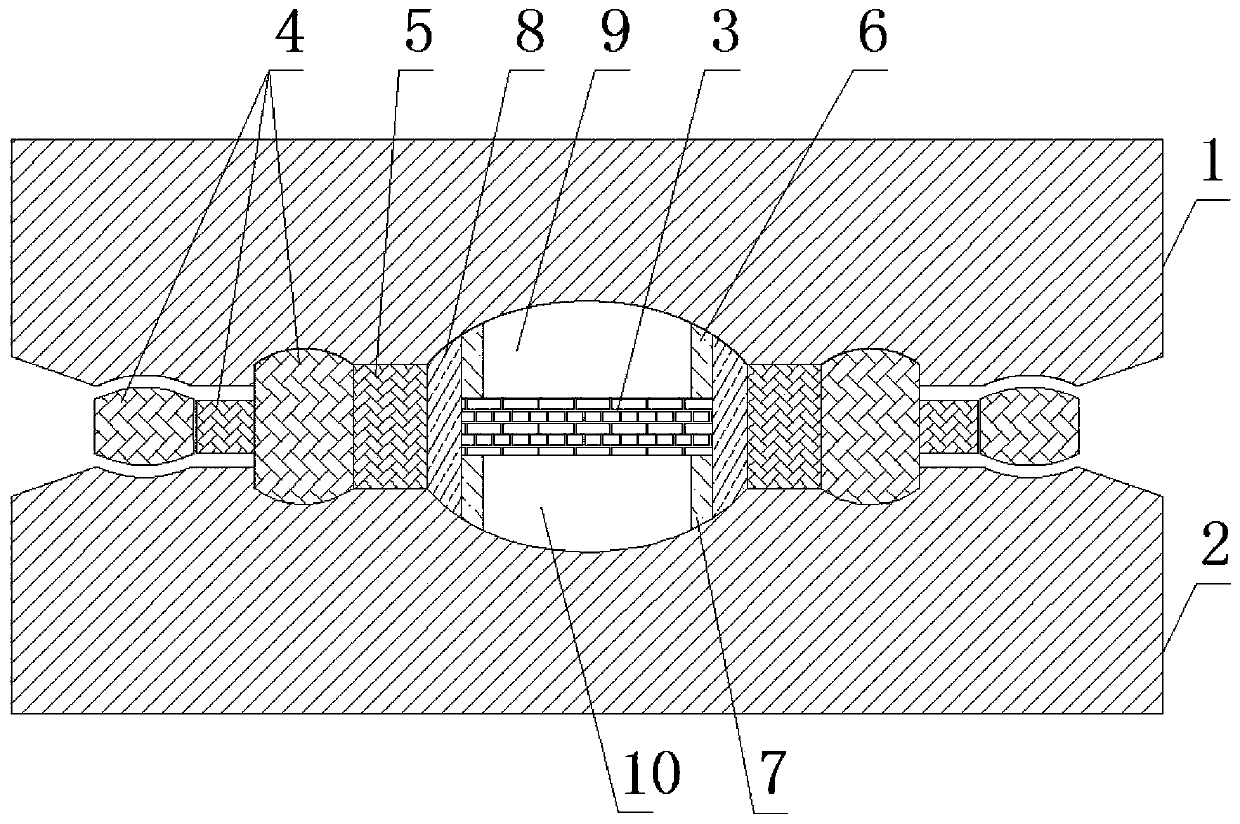

[0021] Such as figure 1 As shown, this embodiment provides a pressure loading device for high-pressure neutron diffraction, including an anvil assembly, the anvil assembly includes an upper anvil 1 and a lower anvil 2 with opposite anvil surfaces, an upper anvil 1, a lower anvil The anvil surface of the anvil 2 is respectively axially inwardly recessed relative to the upper anvil 1 and the lower anvil 2 to form an arc-shaped upper anvil surface and a lower anvil surface, and also includes a gasket assembly and a diamond pressurized sheet 3; the gasket assembly includes The outer cavity gasket 4, the cavity-forming gasket 5, and the cavity-inside gasket are sequentially arranged from outside to inside, wherein the cavity of the cavity-forming gasket 5 forms a pressure cavity with the upper anvil surface and the lower anvil surface, and the diamond pressurized sheet 3 It is arranged in the inner cavity of the cavity-forming gasket 5 and divides the pressure cavity into an upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com