Heating control method of cooking utensil

A technology for cooking utensils and heating control, applied in the directions of temperature control, electric heating fuel, lighting and heating equipment, etc., can solve the problems of low adjustment accuracy, reduced user experience, difficult control, etc., to reduce production costs, improve friendliness, The effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

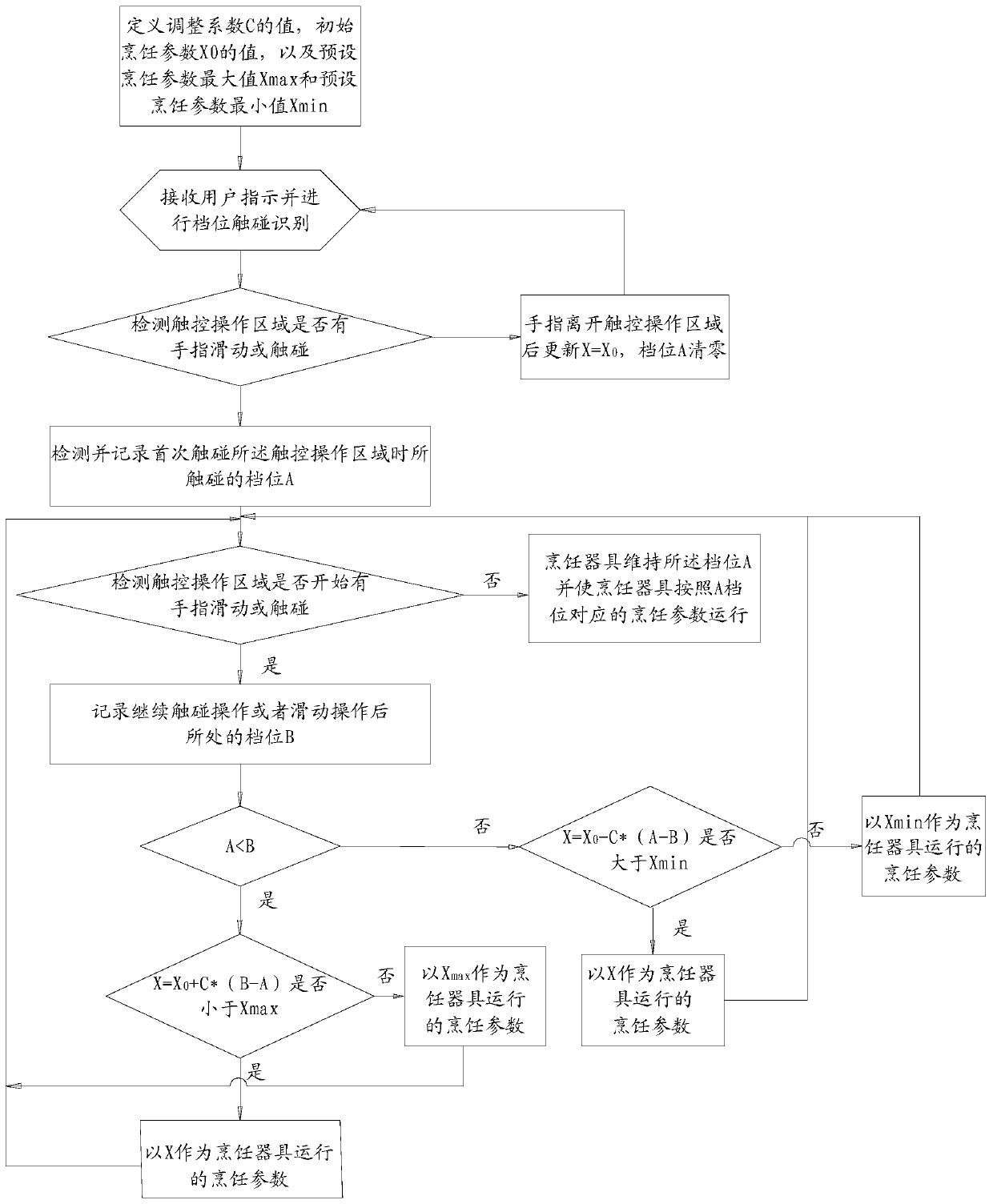

example 1

[0083] Example 1: Assume that the heating time of the cooking utensil is 10 minutes, and the gear that the finger slides or touches the touch operation area for the first time is the second gear of the entire touch operation area, that is, A=2, and then detected The user slides his finger to the right, and the gear he slides to is the third gear, that is, B=3. If the adjustment coefficient C is 5, the heating time becomes 15 minutes. By analogy, if the finger slides to the fifth gear, If B=5, the heating time becomes 25 minutes. When the finger leaves the touch operation area, the heating time is locked and the previously recorded gear position A is cleared.

[0084] Assume that the heating time of the cooking utensil is 90 minutes, and the gear of the finger sliding or touching the touch operation area for the first time is the eighth gear of the entire touch operation area, that is, A=8, and then it is detected that the user’s finger points to Slide to the left, and the gear...

example 2

[0085] Example 2: Assume that the existing heating temperature of the cooking utensil is 80°C, and the gear that the finger slides or touches the touch operation area for the first time is the second gear of the entire touch operation area, that is, A=2, and then detected The user slides his finger to the right, and the gear he slides to is the fifth gear, that is, B=5. If the adjustment coefficient C is 20, the heating temperature becomes 140°C. By analogy, if the finger slides to the sixth gear, Then B=6, the heating temperature becomes 160°C, if the finger slides to the eighth gear, then B=8, the heating temperature becomes 200°C, when the finger leaves the touch operation area, the heating temperature is locked, And clear the gear position A recorded before. If it is detected that the second sliding of the finger or the gear that touches the touch operation area is the twelfth gear, that is, B=12, then X 0 The value of +C*(B-A) is 280°C, if the maximum value of the preset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com