Full-automatic welding line for single-end and double-end power batteries

A power battery, fully automatic technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as low efficiency, complicated battery fixtures, and unstable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings.

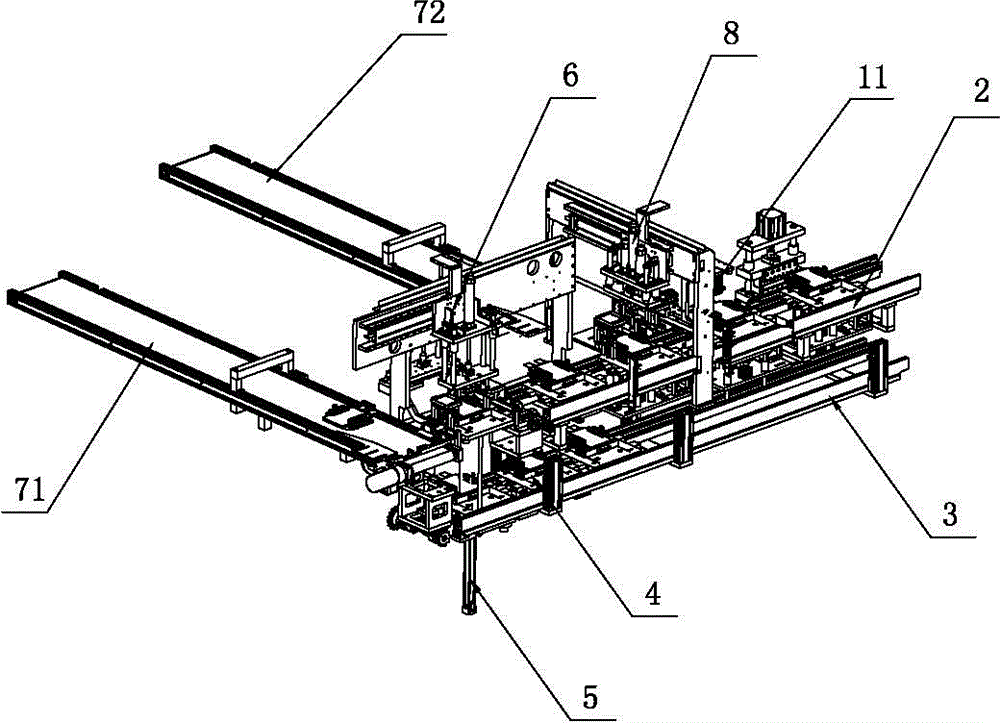

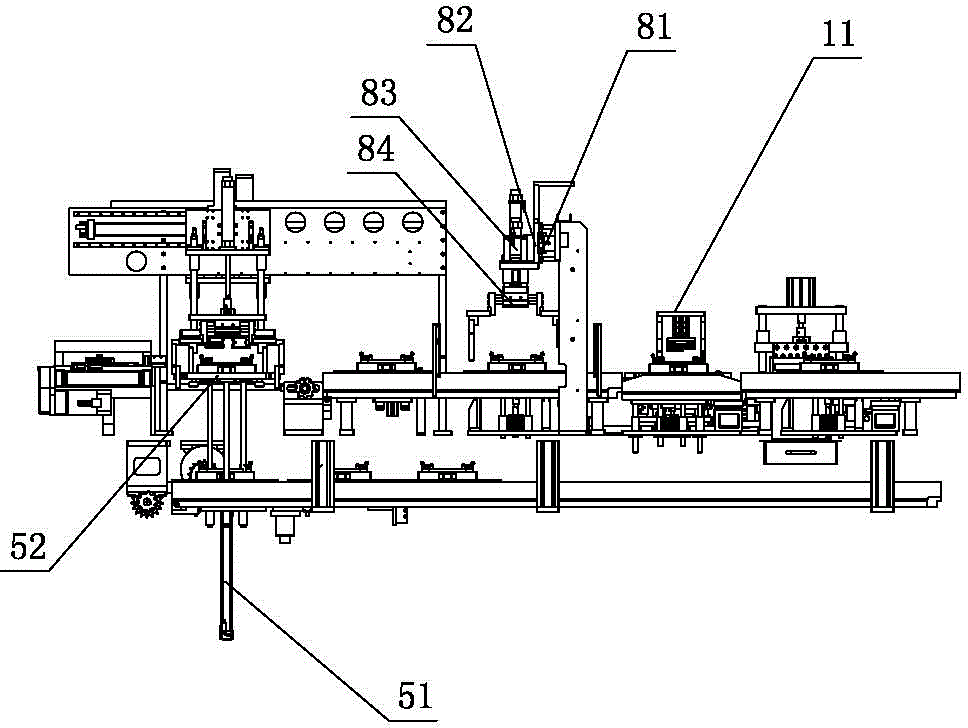

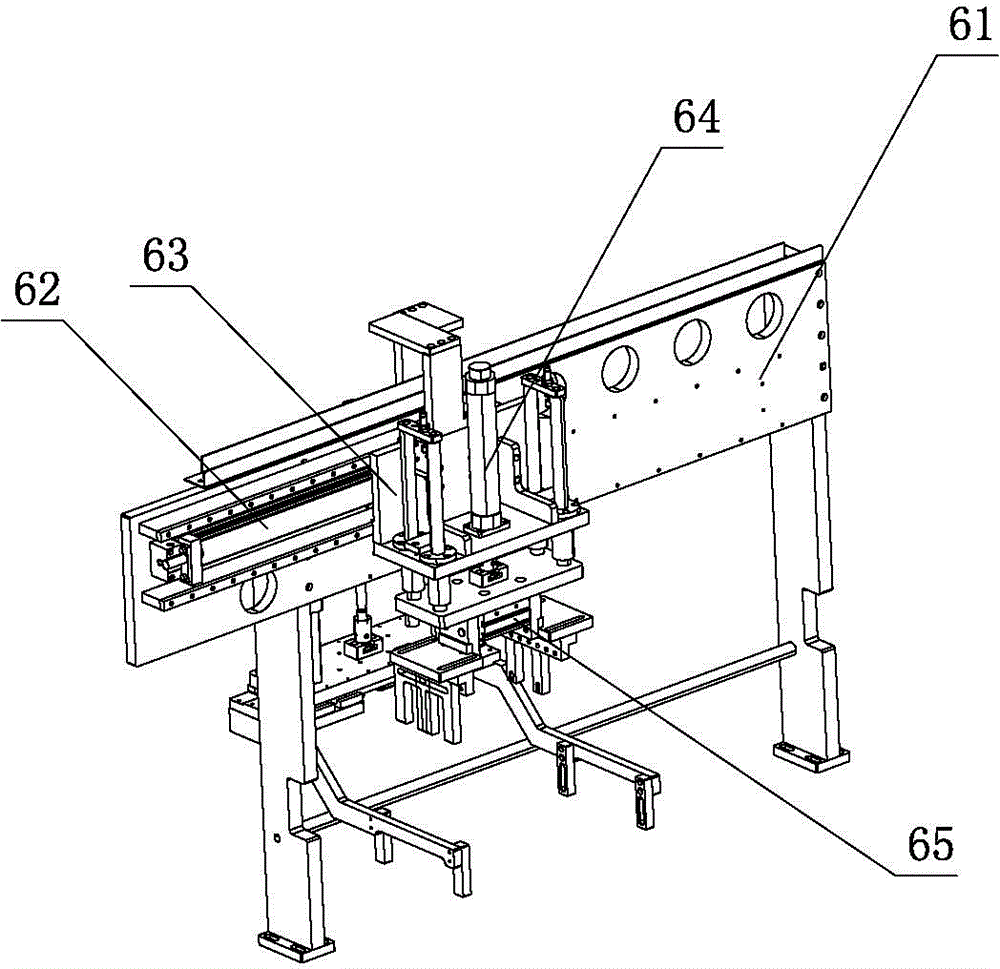

[0044] Such as Figure 1 to Figure 10As shown, a fully automatic welding line for single and double-head power batteries of the present invention includes a frame 1, and the frame 1 is provided with an upper transportation line 2 and a lower transportation line 3, and the upper transportation line 2 and the lower transportation line 3 are provided with a number of trolley fixtures 4 for installing batteries; the trolley fixture 4 includes a trolley part 41 and a fixture part 42, and the fixture part 42 is detachably connected to the trolley part 41; station 11; the front end of the frame 1 is provided with a jig lifting device 5 for sending the trolley fixture 4 from the lower transportation line 3 to the upper transportation line 2; part 41 and the clamp part 42 for splitting the clamp separation device 6; the bottom of the clamp separation device 6 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com