Inner circle slicer

A technology of inner circle slicing and machine base, which is applied in metal processing and other directions, can solve the problems of poor slicing quality, low sensitivity and precision, etc., and achieve the effect of convenient adjustment, simple device setting and firm positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

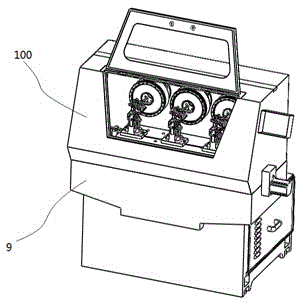

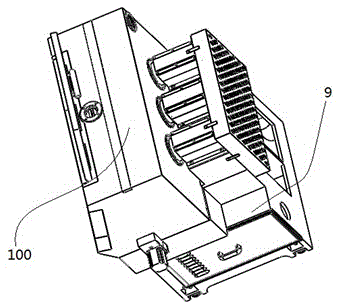

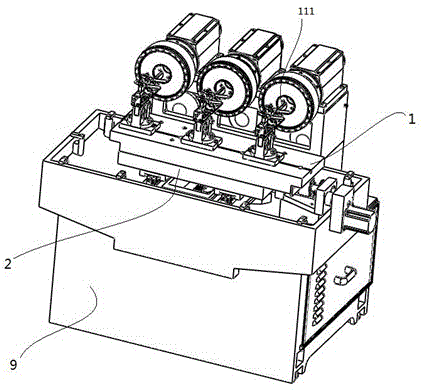

[0101] This embodiment provides a kind of inner circle slicer, such as Figure 1-6 As shown, it includes a base 9, a lower carriage 2 fixedly arranged on the top of the base 9, and an upper carriage 1 installed on the lower carriage 2, and a clip is fixed on the upper carriage 1. A material plate seat holding a material rod 111; the base 9 is also provided with a first feed mechanism for driving the lower carriage 2 and further driving the upper carriage 1 to move along the first direction, and A second feeding mechanism for driving the upper carriage 1 to move in the second direction relative to the lower carriage 2, the second feeding mechanism drives the lower carriage 2 after the first feeding mechanism No follow-up occurs when the carriage 2 moves along the first direction.

[0102] In this example, if Figure 7 , Figure 8 , Figure 9 with Figure 10 As shown, the above-mentioned first fittings are two drive blocks 31 fixedly arranged on the above-mentioned drive as...

Embodiment 2

[0116] This embodiment provides an inner circle slicer, which is an improvement on the basis of Embodiment 1, the difference is: as Figure 7 with Figure 8As shown, the driving block 31 includes a driving column 32 fixedly connected with the driving assembly, and a roller 33 rotatably sleeved on the driving column 32 , and the driving block 31 is in contact with the plane through the outer peripheral surface of the roller 33 . Above-mentioned roller 33 can be sliding bearing, also can be rolling bearing. The advantage of this arrangement is that the sliding of the drive block 31 relative to the slide plate 4 is converted into the rolling of the roller 33 relative to the slide plate 4, which is beneficial to slow down the wear of the relative sliding plane between the drive block 31 and the slide plate 4, thereby extending the slide plate. 4 and the service life of the driving block 31, and improve the sensitivity.

Embodiment 3

[0118] This embodiment provides an inner circle slicer, which is an improvement on the basis of Embodiment 1 or Embodiment 2, the difference is that: Figure 8 As shown, the second feed mechanism also includes a second internal thread member 52 sleeved on the first rotating shaft 51, arranged side by side with the first internal thread member 3 with a certain axial gap and having internal threads, and the second The internally threaded part 52 and the first internally threaded part 3 are mutually tensioned, so that the internal threads of the first internally threaded part 3 and the second internally threaded part 52 are closely fitted with the external threads of the first rotating shaft 51 respectively. .

[0119] The advantage of this arrangement is that since the first rotating shaft 51 and the first internal threaded member 3 are connected through thread fit, after a long time of use, a large thread gap is often formed between the threads, and this kind of thread gap is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com